GRINDING SERVICE:

Grinding process overview:

Grinding is a critical process in component manufacturing, enhancing surface finish and dimensional accuracy. By removing minute amounts of material through abrasive wheels, grinding offers superior control over workpiece precision and tolerances compared to milling or turning. Primarily employed in metalworking, tool manufacturing, and parts production, grinding addresses demanding requirements for surface smoothness and dimensional accuracy at the micrometer level. It is particularly well-suited for machining hard materials such as steel, alloys, and ceramics.

Types and applications of grinding

Grinding is a critical machining process in modern manufacturing, especially when customers demand tight tolerances, high accuracy, and superior surface finish. Different grinding methods are designed to solve specific challenges in precision machining. Below are the most common types of grinding and their industrial applications:

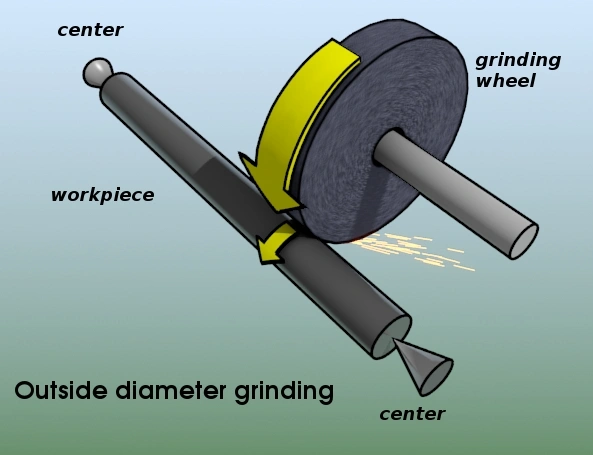

Cylindrical Grinding (External Grinding):

Characteristics:

Designed for machining the outer diameter of cylindrical parts. It ensures roundness and dimensional accuracy with minimal deviation.

Applications:

Widely used for shafts, rollers, and precision spindles, often in the machinery, robotics, and energy sectors.

Cylindrical Grinding (External Grinding):

Characteristics:

Designed for machining the outer diameter of cylindrical parts. It ensures roundness and dimensional accuracy with minimal deviation.

Applications:

Widely used for shafts, rollers, and precision spindles, often in the machinery, robotics, and energy sectors.

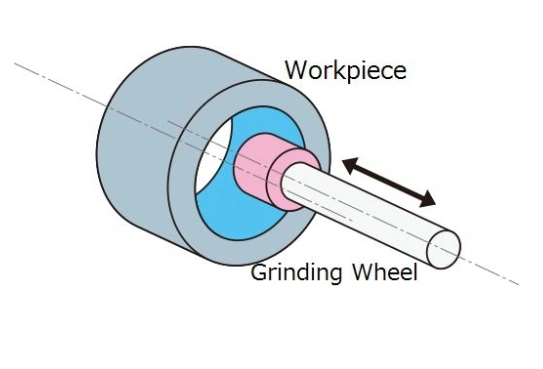

Internal Grinding:

Characteristics:

Focuses on machining internal bores or holes with tight tolerance machining. Capable of reaching deep and narrow cavities.

Applications:

Essential in producing bearing races, bushings, hydraulic cylinders, and other components where internal precision is vital.

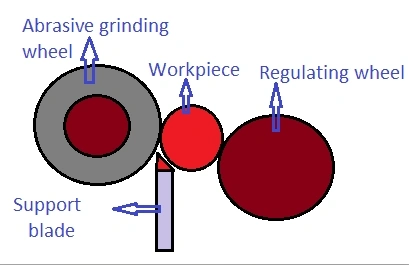

Centerless Grinding:

Characteristics:

Unlike cylindrical grinding, centerless grinding does not require a spindle. Workpieces are supported between a grinding wheel and a regulating wheel. This allows for high-speed production and consistent accuracy.

Applications:

Ideal for mass production of precision parts like pins, rods, and tubes. Frequently used in the medical, automotive, and electronics industries.

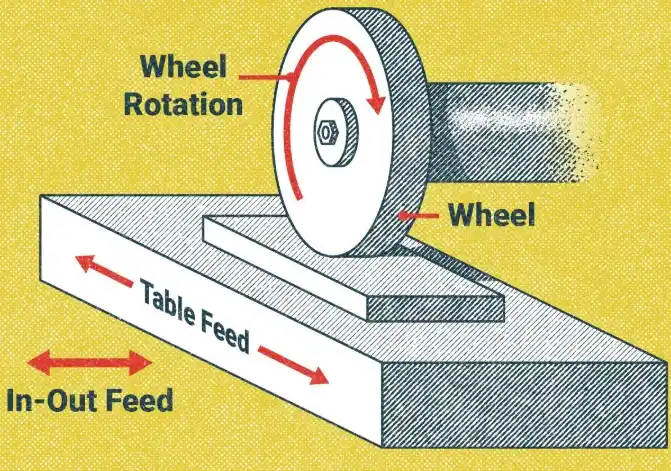

Creep Feed Grinding:

Characteristics:

A less common but highly specialized grinding technique. It uses a very slow feed rate and a large depth of cut, removing material efficiently in a single pass.

Applications:

Particularly useful for machining turbine blades, aerospace alloys, and heat-resistant materials where conventional methods struggle. Known for reducing the number of operations and increasing productivity in complex geometries.

Manual Grinding (Hand Grinding):

Features:

Manual grinding is the most traditional method, relying on operators to use grinding wheels, stones, or handheld tools to finish or repair parts. It is highly flexible and suitable for small-batch, non-standard, or complex-shaped components. Although less efficient, it remains irreplaceable in applications where operator skill and tactile control are required.

Applications:

Commonly used for mold repair, weld grinding, deburring, and small-batch custom work. In maintenance, tool shops, and trial production of special processes, manual grinding provides quick adaptability and complements automated equipment.

FAQ of grinding service

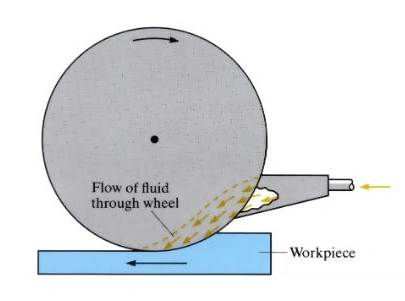

What is the basic principle of grinding?

Grinding is a machining process that uses abrasive particles to micro-cut the workpiece surface through relative motion between the grinding tool and the workpiece, achieving high precision and low surface roughness. Its core lies in the micro-cutting action of the abrasive and the geometric replication of the grinding tool.

What materials are suitable for grinding?

Grinding is applicable to most metals (such as steel, cast iron, and non-ferrous metals) and non-metallic materials (such as ceramics, glass, and crystals). It is particularly suitable for the precision machining of difficult-to-machine materials such as cemented carbide and heat-resistant alloys.

How to choose the right abrasive for grinding?

The selection of abrasives should take into account the hardness of the workpiece material, machining accuracy, and surface quality requirements. For example:

Corundum (aluminum oxide) is suitable for common materials such as hardened steel and cast iron;

Silicon carbide is suitable for high-hardness materials such as cemented carbide and ceramics;

Diamond abrasives are suitable for the precision machining of superhard materials or optical glass.

How to control surface roughness during grinding?

Weldo engineer said :This can be controlled by:

Selecting the appropriate abrasive grit size (fine abrasives reduce roughness);

Adjusting grinding pressure and speed;

Using lubricating coolant to minimize surface damage;

Using multi-stage grinding (rough grinding → fine grinding → polishing).

What are common defects in grinding, and how can they be addressed?

Common defects include:

Surface burn: Frictional heat causes material annealing; reducing the grinding speed or increasing cooling is recommended;

Dimensional deviations: Lapping tool wear or unstable positioning; regular lapping tool repair and fixture inspection are recommended;

Scratches: Embedded abrasive particles or impurities in the lapping tool; cleaning the lapping tool and workpiece is recommended, and using pure abrasive.

What are the differences between lapping, polishing, and superfinishing?

Lapping: Primarily involves micro-cutting, used to remove excess material and correct form accuracy;

Polishing: Primarily involves plastic deformation, primarily reducing surface roughness and improving gloss;

Superfinishing: Further improving surface integrity (such as reducing waviness) beyond lapping; commonly used for precision parts such as bearings.