مع تسريع التصنيع العالمي تحوله نحو إزالة الكربون وخفة الوزن والاقتصاد الدائري, سعر خردة الألومنيوم لم يعد مجرد "اقتباس داخلي" داخل صناعة إعادة التدوير. فهي تؤثر في الوقت نفسه على تكاليف المواد الخام لشركات التصنيع واستراتيجيات الشراء وقرارات التجارة عبر المناطق، وتعكس إلى حد ما وتيرة التغيرات في سوق الألومنيوم الأولي والطلب على المواد الخام.

والأهم من ذلك، يتميز الألومنيوم بخاصية قابليته لإعادة التدوير بشكل متكرر مع تدهور ضئيل للغاية في الأداء. يتزايد عدد البلدان والشركات التي تدمج الألومنيوم المعاد تدويره في أهداف سلسلة التوريد (التكلفة، البصمة الكربونية، الامتثال)، مما جعل الاهتمام بأسعار خردة الألومنيوم في ارتفاع مستمر. ستغطي هذه المقالة المصادر والدرجات، ومنطق التسعير، والمنتجات النهائية المعاد تدويرها، والتحكم في الشوائب، وطرق المعالجة الصناعية، ونطاقات الأسعار الدولية لمساعدتك على بناء إطار فهم كامل لسوق خردة الألومنيوم بسرعة.

المصادر والخصائص الصناعية لخردة الألومنيوم

إن خردة الألومنيوم ليست سلعة موحدة إلى حد كبير؛ فهي تُظهر اختلافات واضحة في الدرجة بسبب الاختلافات في المصدر، ونظام السبائك، ومستوى الشوائب، وصعوبة المعالجة. إن فهم "سبب تصنيف خردة الألومنيوم" هو الخطوة الأولى لفهم "سبب اختلاف الأسعار كثيرًا".

من من منظور التداول الصناعي، تنقسم خردة الألومنيوم عادةً إلى فئتين رئيسيتين: الخردة الصناعية (خردة جديدة) و خردة ما بعد الاستهلاك (الخردة القديمة).

الخردة الصناعية (خردة جديدة)

تأتي الخردة الصناعية من عمليات التصنيع، مثل التصنيع الآلي باستخدام الحاسب الآلي البُرادة ومخلفات الختم وبقايا البثق. وعادة ما يتسم هذا النوع من الخردة بخصائص التركيب الأكثر قابلية للتتبع والتلوث الأكثر قابلية للتحكم، مع مسار معالجة أقصر نسبيًا وتكاليف أقل للتكرير والفرز. ولذلك، في السوق الدولية، غالبًا ما يُنظر إلى الخردة الجديدة في السوق الدولية على أنها مواد وسيطة أعلى جودة لإعادة التدوير، وعادةً ما يكون خصم أسعارها أقل.

خردة ما بعد الاستهلاك (الخردة القديمة)

وتتنوع مصادر خردة ما بعد الاستهلاك، بما في ذلك مواد الألومنيوم من هدم المباني، وقطع غيار السيارات الخردة وأغطية الأجهزة والأبواب والنوافذ. وتتمثل مشاكلها الشائعة في انتشار المواد المختلطة على نطاق واسع والعديد من الشوائب غير المعدنية (الطلاء والطبقات اللاصقة والبلاستيك والمطاط وما إلى ذلك)، مما يتطلب تكاليف أعلى للفرز وإزالة الطلاء والتكرير، كما أنه من المرجح أن تتكبد خسائر في إعادة التدوير. ولذلك، غالبًا ما يكون سعر خردة الألومنيوم من الخردة القديمة أكثر تقلبًا، مع وجود مساحة خصم أكثر وضوحًا.

آلية التحديد الأساسية لسعر خردة الألومنيوم

لا يتم تسعير سعر خردة الألومنيوم بالوزن فقط؛ فهو نتيجة الجمع بين المحتوى المعدني القابل للاسترداد، وتكاليف المعالجة، وخسائر إعادة التدوير، والعرض والطلب في السوق. بشكل عام، يمكن فهم ذلك من خلال أربعة عوامل رئيسية:

- تثبيت سعر الألومنيوم الأساسي: تستخدم معظم خردة الألومنيوم سعر الألومنيوم الأولي كمعيار، ثم تطرح منه تكاليف مثل الفرز والتكرير والفاقد والخدمات اللوجستية.

- السبيكة والدرجة: وكلما كان نظام السبيكة أكثر صفاءً وثباتًا كلما كان من الأسهل الدخول في طرق عالية القيمة مثل البثق/الدرفلة، وكلما ارتفع السعر.

- التلوث والخسائر: النفط، والرطوبة، والأكسدة، وشوائب الحديد/النحاس تقلل من إنتاجية استخلاص المعادن وتزيد من تكاليف المعالجة، مما يؤدي إلى خصومات.

- الاختلافات الإقليمية والسياسات: تؤدي الاختلافات في الطاقة، والامتثال البيئي، ونصف القطر اللوجستي، ومعايير الاستيراد إلى اختلافات في أسعار نفس النوع من خردة الألومنيوم في الأسواق المختلفة.

قيمة إعادة تدوير خردة الألومنيوم

منظور الموارد

وتقلل إعادة تدوير خردة الألومنيوم من الاعتماد على الموارد غير المتجددة مثل البوكسيت، وتخفف من تدهور الأراضي والأضرار البيئية الناجمة عن أنشطة التعدين، وتحسن كفاءة الاستخدام الكلي لموارد الألومنيوم. وعلى المدى الطويل، يساعد على تخفيف الضغط الناجم عن القيود المفروضة على الموارد.

المنظور الاقتصادي

بالمقارنة مع إنتاج الألومنيوم الأولي من الخام، ينطوي الألومنيوم المعاد تدويره على عملية إنتاج أقصر واستهلاك أقل بكثير للطاقة، مما يؤدي إلى انخفاض التكاليف الإجمالية بشكل كبير. وهذا يعطي خردة الألومنيوم قيمة اقتصادية مستقرة في السوق ويوفر لشركات التصنيع قدرة تنافسية أقوى من حيث التكلفة.

المنظور البيئي

يمكن إعادة تدوير الألومنيوم عدة مرات بأقل قدر من التدهور في الأداء. كما أن إعادة التدوير تقلل بشكل كبير من استهلاك الطاقة وانبعاثات الكربون، مع تقليل توليد الخبث وانبعاثات الملوثات أثناء الصهر. وبالتالي فهي مسار رئيسي نحو التصنيع منخفض الكربون والتنمية المستدامة.

المنظور الصناعي

تدعم إعادة تدوير خردة الألومنيوم سلسلة صناعية كاملة تشمل الجمع والصهر الثانوي والمعالجة النهائية. يُستخدم الألومنيوم المعاد تدويره الآن على نطاق واسع في السيارات والبناء والمعدات الصناعية، مما يعزز تطوير الاقتصاد الدائري ويوفر لقطاع التصنيع مصدرًا مستقرًا ومستدامًا للمواد الخام.

هل هناك فرق بين الألومنيوم المعاد تدويره والألومنيوم المنتج من الخام؟

من من منظور علم المواد، لا يتم تحديد الأداء الميكانيكي للألومنيوم من خلال ما إذا كان معاد تدويره، ولكن من خلال تركيبة السبيكة، والتحكم في الشوائب، والبنية المجهرية، وطرق المعالجة. عندما يكون التحكم في التركيب وظروف المعالجة متماثلة، يمكن للألومنيوم المعاد تدويره والألومنيوم الأولي المنتج من الخام أن يحقق نفس مستويات القوة والاستطالة والصلابة والأداء المتعلق بالتعب؛ وبالتالي، لا يوجد فرق متأصل في الأداء بين الاثنين.

العوامل الأساسية التي تحدد الأداء الميكانيكي

تعتمد الخواص الميكانيكية للألومنيوم بشكل أساسي على نظام السبيكة (مثل نسب Si وMg وCu وZn)، وما إذا كان يتم التحكم في عناصر الشوائب بشكل صحيح، وطريقة الصب أو طريقة معالجة التشوه، وظروف المعالجة الحرارية اللاحقة (مثل T4 أو T6). وطالما كانت هذه العوامل الرئيسية متسقة، فإن مصدر المادة نفسها لا يغير من أدائها الميكانيكي.

هل الألومنيوم المعاد تدويره أقل جودة في الأداء؟

وإذا لم تكن مراقبة الفرز والتركيب كافية، فقد يُظهر الألومنيوم المعاد تدويره تقلبات في الأداء. وبالإضافة إلى ذلك، يشيع استخدام الألومنيوم المعاد تدويره في التطبيقات المتوسطة والمنخفضة المخاطر مثل الأجزاء الهيكلية والأغلفة بينما تميل المجالات المتطورة إلى تفضيل الألومنيوم الأولي، مما يخلق انطباعًا بأن الاختلافات في التطبيق هي اختلافات في الأداء.

كيف يمكن للألومنيوم المعاد تدويره أن يحقق أداءً يضاهي أداء الألومنيوم الأولي؟

عندما يحافظ الألومنيوم المعاد تدويره على تركيبة سبيكة مستقرة، ويتم التحكم في الشوائب ضمن الحدود القياسية، ويتم تطبيق نفس طرق المعالجة والمعالجة الحرارية التي يتم تطبيقها على الألومنيوم الأولي، يمكن أن تتطابق خصائصه الرئيسية - مثل قوة الشد وقوة الخضوع والاستطالة وأداء التعب - مع خصائص الألومنيوم الأولي. في معظم التطبيقات الصناعية وتطبيقات التصنيع باستخدام الحاسب الآلي، لا يمكن التمييز بين الاثنين تقريبًا.

سيناريوهات استخدام الألومنيوم المعاد تدويره والألومنيوم الأولي

تطبيقات الألومنيوم المعاد تدويره:يُستخدم الألومنيوم المعاد تدويره على نطاق واسع في قطع غيار السيارات، وأغطية المعدات الصناعية، والمكونات الهيكلية، والمقاطع المعمارية، والأجزاء العامة المصنوعة باستخدام الحاسب الآلي. وتركز هذه التطبيقات بشكل أكبر على الأداء العام والتحكم في التكلفة واستقرار التوريد، ومع التحكم المناسب في تركيبة السبائك والشوائب، يمكن للألومنيوم المعاد تدويره أن يلبي معظم المتطلبات الصناعية.

تطبيقات الألومنيوم الأولي:يُستخدم الألومنيوم الأولي بشكل أكثر شيوعًا في مجال الطيران، والمكونات الهيكلية عالية السلامة، والتطبيقات ذات المتطلبات الصارمة للغاية لاتساق الدُفعات وإمكانية التتبع والاعتماد. وعادةً ما تتطلب هذه المجالات تحكمًا أكثر صرامة في المواد وأنظمة موحدة، مما يجعل الألومنيوم الأساسي الخيار المفضل.

أنظمة سبائك الألومنيوم الرئيسية المناسبة للألومنيوم المعاد تدويره

نظام Al-Si (سبائك الألومنيوم المصبوب)

نظام Al-Si هو أكثر أنظمة السبائك نضجًا واستخدامًا على نطاق واسع للألومنيوم المعاد تدويره، مع قدرة تحمل عالية نسبيًا للشوائب. وتشمل الدرجات الشائعة ADC12 وA380 وA380 وA380 AlSi9Cu3 وAlSi12. تُستخدم هذه السبائك بشكل أساسي في علب السيارات، وعلب المحركات، والأجزاء الهيكلية المصبوبة، وتمثل أعلى نسبة من تطبيقات الألومنيوم المعاد تدويره.

نظام Al-Si-Mg (سبائك الصب القابلة للمعالجة الحرارية)

بإضافة المغنيسيوم المغنيسيوم إلى نظام Al-Si، يمكن تحسين القوة والمتانة من خلال المعالجة الحرارية T6. تشمل الدرجات النموذجية A356 وA357 وA357 وASi7Mg، والتي تُستخدم على نطاق واسع في المكونات الهيكلية للسيارات والمسبوكات الحاملة. ومع التحكم المناسب في الشوائب، يمكن استخدام الألومنيوم المعاد تدويره بشكل موثوق في هذه السبائك.

نظام Al-Mg (السلسلة 5xxx)

تُعرف السلسلة 5xxx بمقاومتها الجيدة للتآكل وقابليتها للتشكيل. وتُستخدم الدرجات الشائعة مثل 5052 و5083 و5754 على نطاق واسع في بناء السفن والمعدات الكيميائية وأجزاء هياكل السيارات. وعادةً ما تسمح المنتجات من الدرجة الصناعية باستخدام نسبة محكومة من الألومنيوم المعاد تدويره تحت رقابة صارمة على الشوائب.

نظام Al-Mg-Si (السلسلة 6xxx)

إن السلسلة 6xxx هو نظام السبائك الرئيسي للمقاطع الجانبية المعمارية والصناعية، بما في ذلك 6061 و6063 و6082. وعلى الرغم من أنها تتطلب تناسقًا أعلى في التركيب، إلا أنه يمكن استخدام الألومنيوم المعاد تدويره بثبات ضمن نظام إعادة التدوير الناضج. وتُستخدم هذه السبائك بشكل شائع في المقاطع الجانبية ودعامات المعدات والأجزاء المشكّلة باستخدام الحاسب الآلي.

نظام Al-Cu (السلسلة 2xxx)

توفر السلسلة 2xxx قوة عالية ولكنها حساسة للشوائب. تشمل الدرجات النموذجية 2011 و2024، وتستخدم بشكل أساسي في المكونات الميكانيكية عالية القوة. وعادةً ما تتطلب التطبيقات الخاصة بالفضاء الجوي ألومنيوم أولي، بينما قد تستخدم التطبيقات الصناعية الألومنيوم المعاد تدويره بطريقة محكومة.

نظام Al-Zn-Mg (السلسلة 7xxx)

تتألف السلسلة 7xxx من سبائك فائقة القوة مثل 7003 و7075، والتي تتطلب رقابة صارمة للغاية على التركيب والشوائب. يُستخدم الألومنيوم المعاد تدويره بشكل أساسي في المكونات الهيكلية غير الحرجة وغير المتعلقة بالسلامة، ونطاق استخدامه محدود نسبيًا.

ما هي المنتجات الصناعية التي يمكن إعادة تدوير خردة الألومنيوم إليها؟

يفهم الكثير من الناس الألومنيوم المعاد تدويره على أنه "بديل منخفض الجودة"، ولكن في النظم الصناعية، تم استخدام الألومنيوم المعاد تدويره على نطاق واسع. ويكمن المفتاح في إمكانية التحكم في الشوائب من خلال الفرز والتكرير، وما إذا كان يمكن تثبيت تركيبة السبيكة بحيث تكون لها سمات صناعية يمكن التحقق منها ويمكن توريدها على دفعات.

سبائك الألومنيوم الثانوية

سبائك الألومنيوم الثانوية هي واحدة من أكثر أشكال التداول شيوعًا، مما يسهل التجارة الموحدة والنقل وإدارة المخزون، كما يسهل أيضًا عملية التجميع النهائي والتحكم في الدُفعات. وعادةً ما تكون بمثابة المادة الخام الأساسية لعمليات مثل الصب والصب بالقالب والبثق والدرفلة، مما يربط بين نهاية إعادة التدوير ونهاية التصنيع.

مواد سبائك الألومنيوم لصب القوالب والصب

تستخدم السيارات، والدراجات النارية، وأغطية المحركات، وأجسام المضخات، والأجزاء الهيكلية المختلفة للمساكن كمية كبيرة من الألومنيوم المعاد تدويره. بالنسبة لهذه التطبيقات، فإن "ما إذا كان الألومنيوم المعاد تدويره أساسيًا" ليس المؤشر الوحيد؛ حيث تولي الشركات اهتمامًا أكبر لما إذا كان أداء الصب والتحكم في الخبث والمسامية والقوة والاتساق يفي بالمعايير. وطالما أن نظام مراقبة الجودة ناضج، يمكن للألومنيوم المعاد تدويره أن يلبي الطلب بالكامل.

مقاطع الألومنيوم المعاد بثقها والأجزاء الهيكلية الصناعية

بالنسبة للخردة عالية الجودة القابلة لإعادة البثق (خاصةً أنواع البثق النظيف)، يمكن أن يدخل الألومنيوم المعاد تدويره في مسار التشكيل الجانبي ويستخدم في إطارات المعدات الصناعية، وهياكل المباني، وأنظمة الأبواب والنوافذ، والأقواس الكهروضوئية، وما إلى ذلك. ونظرًا لأن البثق يتطلب اتساقًا أعلى للمواد الخام، فإن المواد الخام التي يمكن أن تدخل في هذا المسار عادةً ما يكون لها دعم سعر أقوى.

ألواح/قضبان الألومنيوم للتشغيل الآلي باستخدام الحاسب الآلي (بنسبة معاد تدويرها)

وعلى فرضية أن تركيبة السبيكة مستقرة ويتم التحكم في الشوائب، يمكن أيضًا استخدام الألومنيوم المعاد تدويره في المنتجات شبه المصنعة مثل ألواح الألومنيوم وقضبان الألومنيوم، كما يمكن أن يدخل في التصنيع باستخدام الحاسب الآلي. بالنسبة للعديد من التطبيقات غير المتعلقة بالفضاء الجوي، يوفر الألومنيوم المعاد تدويره توازنًا أفضل بين الأداء والتكلفة، مع تقليل البصمة الكربونية المتعلقة بالمادة.

كيفية إزالة الشوائب في عملية إعادة تدوير خردة الألومنيوم؟

لجعل خردة الألومنيوم مؤهلة كمواد خام صناعية، يجب أن تمر بعملية تنقية منهجية. لا يحدد التحكم في الشوائب ما إذا كان الألومنيوم المعاد تدويره يمكن أن يدخل في مسارات العمليات عالية المتطلبات فحسب، بل يؤثر أيضًا بشكل مباشر على عائد الاسترداد والاستقرار واتساق المنتج النهائي.

فرز فيزيائي متعدد المراحل: إزالة المكونات غير الألومنيوم قدر الإمكان أولاً

استخدم الفصل المغناطيسي لإزالة الحديد والفولاذ، واستخدم الفصل بالتيار الدوامي لفصل الألومنيوم عن المعادن الأخرى، ثم تعاون مع الغربلة وتصنيف حجم الجسيمات لتقليل الفاقد الناجم عن المعالجة غير المتساوية؛ وعندما تسمح الظروف، يمكن أيضًا استخدام الفرز الكثافة أو الفرز البصري لزيادة تقليل نسبة المواد المختلطة وتقليل عبء التكرير اللاحق.

التنظيف والمعالجة المسبقة: إزالة الزيت، وإزالة الماء، وإزالة المواد العضوية

بالنسبة للبُرادة/البُرادة بنظام التحكم الرقمي CNC، تُعد المعالجة المسبقة ذات قيمة خاصة: يمكن أن تقلل إزالة الشحوم من أبخرة الصهر والشوائب، ويمكن أن يقلل التجفيف من الرطوبة لتجنب مخاطر تناثر الصهر؛ وتساعد إزالة المواد العضوية مثل الطلاءات والطبقات اللاصقة على تقليل الشوائب غير المعدنية وتحسين معدلات تأهيل المنتج النهائي واستقرار المظهر.

تكرير الصهر وتصحيح التركيب: جعل المادة "مستقرة"

في مرحلة الصهر، غالبًا ما يتم استخدام نزع الهيدروجين لتقليل عيوب المسامية، ويتم استخدام إزالة الخبث والترشيح لتقليل شوائب الأكسيد وجزيئات الشوائب، ثم يتم إجراء تعويض السبائك وفقًا للدرجة المستهدفة (مثل السيليكون والمغنيسيوم والعناصر الأخرى)، ويتم استخدام التحكم في الدُفعات لضمان تقلبات الأداء التي يمكن التحكم فيها. وغالبًا ما يحدد مدى إمكانية تنفيذ هذه الخطوة بشكل جيد ما إذا كان الألومنيوم المعاد تدويره قابلاً للاستخدام الصناعي.

هل يمكن استخدام خردة الألومنيوم كمادة خام صناعية؟

لا يمكن استخدام الألومنيوم المعاد تدويره كمادة خام صناعية فحسب، بل إنه في العديد من السيناريوهات يكون "فعالاً من حيث التكلفة". مقارنة بسيطة تجعل من السهل فهم الأمر: ألومنيوم أولي تأتي من البوكسيت وتحتاج إلى المرور عبر إنتاج الألومينا والصهر الإلكتروليتي؛ حيث إن العملية طويلة، واستهلاك الطاقة مرتفع، وهيكل التكلفة أثقل؛ في حين أن ألومنيوم معاد تدويره يتم الحصول عليها من خلال إعادة تدوير مواد الألومنيوم الموجودة وتنقيتها وصهرها وتعديل تركيبها لإعادة استخدامها، مع مسار معالجة إجمالي أقصر واستهلاك أقل للطاقة. أيضًا، نظرًا لأن خواص مادة الألومنيوم تحدد أنه يمكن إعادة تدويرها عدة مرات مع انخفاض طفيف للغاية في الأداء، فإن الألومنيوم المعاد تدويره له قيمة إعادة تدوير طويلة الأجل.

في التطبيقات العملية، طالما أن التحكم في الشوائب وثبات التركيب واتساق الدفعات بشكل جيد، يمكن للألومنيوم المعاد تدويره أن يدخل روابط التصنيع بشكل كامل ومستقر. كما أن العديد من العملاء الدوليين لم يعودوا يركزون على "ما إذا كان ذلك أساسيًا"، بل يركزون أكثر على إمكانية التتبع، وإمكانية التحقق، والتسليم المستقر، وهو أكثر عملية للمشتريات الصناعية.

تشمل الاستخدامات الشائعة السيارات والنقل (العلب، والأقواس، والأجزاء الهيكلية)، والمعدات الصناعية (العلب والإطارات)، وأنظمة البناء والمظهر الجانبي، وبعض الأجزاء الهيكلية للطاقة الجديدة، والأجزاء العامة المصنعة باستخدام الحاسب الآلي. ويعتمد مدى إمكانية استخدامه بشكل أساسي على الدرجة المستهدفة وحدود الشوائب ومتطلبات الأداء والمظهر الخارجي للمنتج.

طرق المعالجة الصناعية الرئيسية للألومنيوم المعاد تدويره

لا تكمن قيمة الألومنيوم المعاد تدويره في إعادة التدوير نفسها فحسب، بل تكمن أكثر في إمكانية دخوله في طرق معالجة ذات قيمة مضافة أعلى. إن طرق المعالجة المختلفة لها متطلبات مختلفة لنقاء المواد الخام، واستقرار التركيبة، والتحكم في العيوب، وستؤثر بدورها على مستوى سعر خردة الألومنيوم المعاد تدويره وتصنيفها.

1) الصب والصب بالقالب

يُعد الصب/السبك بالقالب أحد أكثر الوجهات النهائية شيوعًا للألومنيوم المعاد تدويره، وهو مناسب للأشكال المعقدة والإنتاج الضخم. وتولي الصناعة اهتمامًا أكبر للسيولة والتحكم في الخبث/المسامية وحدود الشوائب، لأن هذه العوامل تؤثر بشكل مباشر على قوة الصب وجودة السطح ومعدل الخردة.

2) البثق

البثق أكثر "انتقائية" فيما يتعلق بالمواد الخام ويتطلب اتساقًا أعلى في نظام السبائك والدُفعات. يمكن للمواد الخام غير المستقرة أن تؤدي بسهولة إلى حدوث عيوب في السطح وتقلبات في الأداء وتآكل القالب، لذلك غالبًا ما تكون الخردة عالية الجودة التي يمكن أن تدخل في مسار البثق (مثل البثق النظيف) ذات سعر أفضل.

3) الدرفلة: مسار الصفيحة/الشريط/الرقاقة

تُستخدم الدرفلة لإنتاج منتجات نصف مصنعة مثل صفائح الألومنيوم وشريط الألومنيوم، وهي أكثر حساسية للشوائب والثقوب وجودة السطح، لذا فإن متطلبات تنقية المواد الخام والتحكم في الدُفعات أكثر صرامة. عندما يتم التحكم فيها بشكل صحيح، يمكن أن يوفر الألومنيوم المعاد تدويره مصدرًا مستقرًا للصفائح/الشرائط الصناعية؛ في حين أن تطبيقات التعبئة والتغليف عادةً ما يكون لها عتبات أعلى للشوائب وعيوب السطح.

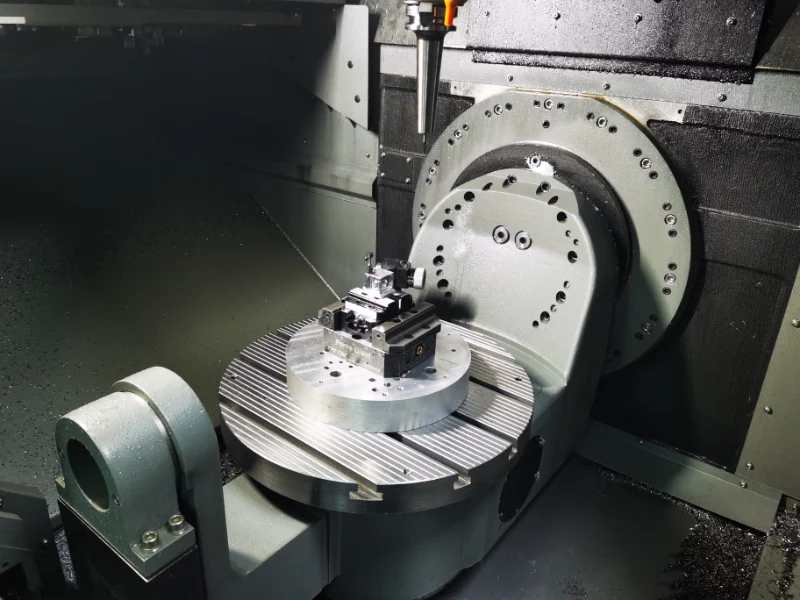

4) التصنيع الآلي باستخدام الحاسب الآلي

عادةً ما يُصنع الألومنيوم المعاد تدويره أولاً في سبائك الألومنيوم أو ألواح الألومنيوم أو قضبان الألومنيوم، ثم يدخل في عمليات الطحن والخراطة والحفر والاستدقاق باستخدام الحاسب الآلي للقطع الصناعية العامة ومكونات معدات التشغيل الآلي والأجزاء الهيكلية. يركز هذا المسار بشكل أكبر على اتساق دفعة المواد والتحكم في العيوب (مثل الشوائب/البقع الصلبة، والمسامية، وجودة السطح)، لأنها تؤثر بشكل مباشر على استقرار التصنيع الآلي، وعمر الأداة، واتساق مظهر الطلاء بأكسيد الألومنيوم/طلاء الأجزاء اللاحقة.

5) التزوير

في السيناريوهات ذات المتطلبات الأعلى للكثافة ومقاومة الإجهاد، يمكن لبعض الألومنيوم المعاد تدويره (بعد التحكم في التركيب والبنية المجهرية) أن يدخل أيضًا في عمليات التشكيل. يمكن للتشكيل أن يحسّن البنية المجهرية والموثوقية بشكل كبير، ولكن له متطلبات أكثر صرامة للمواد الخام وأنظمة المعالجة الحرارية، وينتمي إلى مسار عتبة أعلى.

6) تعدين المساحيق وتصنيع المواد المضافة (المسحوق/التصنيع الإضافي)

سيقوم عدد قليل من التطبيقات المتطورة بتحضير مواد الألومنيوم المتطورة إلى مسحوق لتحويلها إلى مسحوق تعدين أو تصنيع المواد المضافة. هذا المسار له متطلبات عالية للغاية من حيث النقاء وتوزيع حجم الجسيمات والتحكم في محتوى الأكسجين، وهو أكثر ملاءمة كاتجاه تكميلي للاتجاه لتغطية تطوير العمليات المستقبلية واحتياجات التطبيقات المتطورة.

7) إعادة الصهر والسبك والدرجات المخصصة (إعادة الصهر والسبك)

من خلال التحكم في تناسب السبائك وتكريرها، يمكن إعادة تعريف الألومنيوم المعاد تدويره كمادة هندسية تلبي متطلبات الأداء المحددة، وتخدم أنظمة مثل سبائك صب السيارات، وسبائك الأجزاء الهيكلية الصناعية، وسبائك الآلات العامة، مما يحقق ترقية من "خردة" إلى "مادة خام صناعية يمكن التحقق منها".

النطاق المرجعي لأسعار خردة الألومنيوم في السوق الدولية (بالدولار الأمريكي)

ويساعد فهم نطاقات الأسعار الدولية في الحكم على ما إذا كانت الأسعار المحلية تنحرف عن مستوى معقول، كما يسهل أيضًا وضع معايير مرجعية للصادرات أو المشتريات عبر الأقاليم. وفيما يلي نطاقات التداول الشائعة في السوق الدولية (وهي تتقلب حسب بورصة لندن للمعادن والمعادن الأخرى، والعرض والطلب الإقليمي، وحجم الدفعة، والمواصفات، ودرجات الجودة):

| النوع | نطاق السعر (دولار أمريكي/طن متري) |

|---|---|

| بثق الألومنيوم النظيف | $1,600 - $2,200 |

| الألومنيوم UBC (علب المشروبات المستعملة) | $1,300 - $1,900 |

| خردة الألومنيوم المصبوب | $1,100 - $1,600 |

| خراطة الألومنيوم | $800 - $1300 |

| خردة الألومنيوم المختلطة | $700 - $1,100 |

| سبائك الألومنيوم الثانوية | $1,900 - $2,400 |

من منظور إقليمي: غالبًا ما تكون تكاليف الامتثال والتوحيد القياسي في أمريكا الشمالية والاتحاد الأوروبي أعلى، لذلك من المرجح أن تحمل المواد عالية الجودة علاوة؛ أما جنوب شرق آسيا والهند فهي أكثر حساسية للأسعار وأكثر تقلبًا؛ وقد يُظهر الشرق الأوسط، بسبب هيكل الطاقة ومزايا تكلفة الصهر، منطقًا مختلفًا للتكلفة والتسعير لفئات معينة.

الخاتمة

بشكل عام، يُعد سعر خردة الألومنيوم إشارة رئيسية لسلسلة التوريد التي تربط بين إعادة التدوير والصهر الثانوي والتصنيع: فهو يتحرك مع ظروف سوق الألومنيوم الأولية بينما يعكس أيضًا قابلية استخدام الخردة وصعوبة المعالجة والطلب النهائي. إذا كنت تعمل في مجال إعادة التدوير أو التجارة أو المشتريات، فابحث فيما وراء التسعير الحالي من خلال تتبع التغيرات في عائد الاسترداد وتكاليف المعالجة، والتحولات في الطلب عبر المسارات الرئيسية (الصب والبثق والدرفلة والحاسوب باستخدام الحاسب الآلي)، وانقطاع الإمداد المحتمل من السياسة أو الخدمات اللوجستية أو السعة - حتى تتمكن من الربط بين السعر والدرجة والاستخدام النهائي لاتخاذ قرارات أكثر استقرارًا ودقة.