Over the past century, aerospace technology has enabled humanity to realize the dream of flight while gathering atmospheric and geographical data from space and other planets. The success of every mission relies on the seamless coordination of millions of precision components within aircraft (or other flying vehicles).CNC machining technology provides a solid foundation for manufacturing these components. The following content serves as a Cnc machining aerospace guide, analyzing major incidents in human aerospace history and their causes to profoundly illustrate the critical importance of CNC machining.

Cnc machining part for Aerospace: Micron-level precision requirements

Traditional hand-milled and ground components are relatively coarse and only suitable for everyday equipment. They cannot match the advanced CNC lathe machining technology in terms of dimensional tolerances, surface finish on different planes, surface treatment, and other performance requirements.

During flight, especially when ascending beyond Earth’s gravity, aircraft (aircraft) endure high temperatures, high pressure, vibrations, and stresses from various directions. Therefore, the production precision and machining requirements for each component are extremely high.

Micron-Level Precision and Reproducibility: Advanced CNC machining achieves tolerances at the micron or even sub-micron level, ensuring precise component assembly and optimizing overall structural performance.

This standardized computer-programmed machining is crucial for mass production, guaranteeing consistent manufacturing standards and reducing reliance on manual inspection.

High-Standard Complex Shapes: To meet lightweighting standards and aerodynamic requirements, modern spacecraft demand numerous complex geometries, curved surfaces, and thin-walled components that defy manual fabrication. 4-axis and 5-axis CNC machining precisely produces prototypes and batch parts according to blueprints.

Minimizing High-Value Material Waste: Titanium alloys and nickel-based superalloys, prized for their exceptional properties, are extensively used in critical spacecraft components—yet these materials carry significant cost. Under reliable computer program control, CNC machining enables tools to mechanically execute precise path movements and cutting strategies, preventing damage to workpieces during processing that could occur with manual intervention.

Review of Aerospace Accident Cases

Defective components can lead to mission failure and even significant human loss in space exploration—truly demonstrating how “a thousand-mile dyke collapses through an ant’s hole.” These tragic lessons underscore how crucial CNC machining is for ensuring component quality and flight safety.

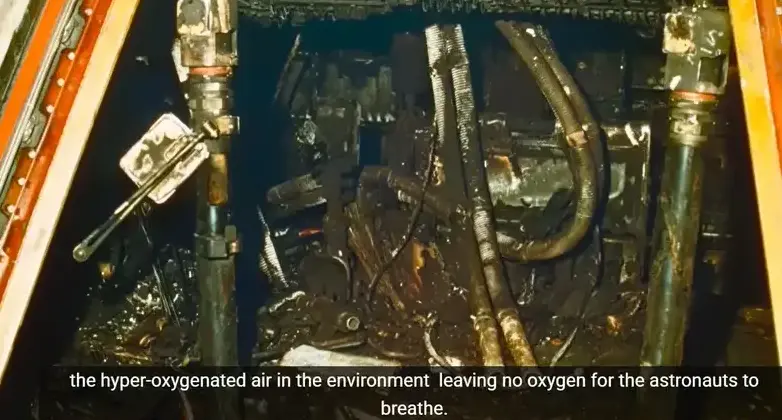

Apollo 1 Fire (1967)

During a routine test, a fire erupted inside the Apollo 1 command module, tragically killing all three astronauts.

The accident resulted from multiple factors: a pure oxygen environment, flammable materials, and electrical short circuits. The investigation revealed numerous manufacturing and assembly defects, including faulty wiring harness routing and insulation, as well as flaws in the hatch design, production, and installation.

This incident underscores that in aerospace manufacturing, no step can be overlooked. Material selection, machining precision, and assembly quality must meet the highest standards—any lapse risks triggering a chain reaction.

CNC machining enhances the precision of metal and plastic components like wire clamps, connectors, and hatch latches on space shuttles, ensuring dimensional accuracy and reliable operation. This significantly reduces the probability of accidents and casualties caused by mechanical wiring failures.

Challenger Space Shuttle Disaster (1986)

Just 73 seconds after liftoff, the Challenger suddenly exploded and disintegrated, killing all seven astronauts.

The direct cause was the failure of the O-ring seals in the right solid rocket booster (SRB) during flight. Extreme cold had frozen the O-rings, causing them to lose elasticity and seal integrity. This allowed hot combustion gases to leak, eventually burning through the external fuel tank.

CNC machining proved critical here. While the O-ring itself was rubber, the grooves and connecting fittings it interacted with were metal. The dimensional accuracy, surface finish, and geometric tolerances of these metal components directly impacted the O-ring’s sealing effectiveness.

If the groove dimensions are machined inaccurately or the surface roughness fails to meet aerospace standards, the O-ring may malfunction—even if the O-ring itself is flawlessly manufactured. This case made me realize that every minute metal/plastic component,along with the precision and performance requirements of their connecting parts, plays an indispensable role in the overall safety of an aircraft. And this is precisely where CNC machining excels.

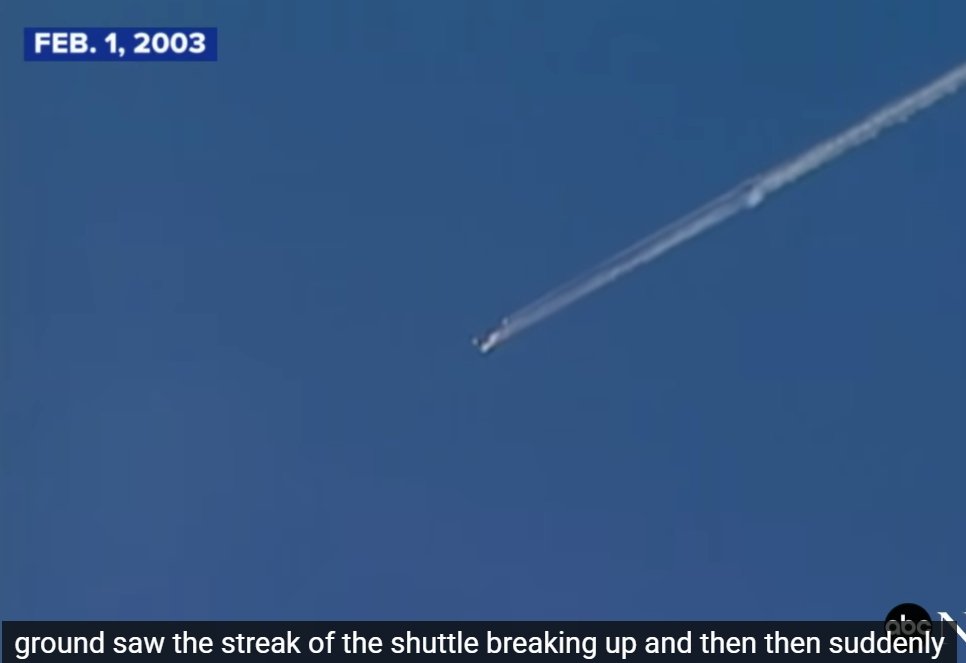

Space Shuttle Columbia Disaster (2003)

The Columbia disintegrated during reentry, killing all seven astronauts aboard.

The accident occurred when a piece of foam insulation detached from the external fuel tank during launch, striking the leading edge of the shuttle’s left wing and causing damage. Upon atmospheric reentry, the damaged wing section could not withstand extreme temperatures. High-pressure hot gases penetrated the wing structure, ultimately leading to its disintegration.

While the foam loss was the immediate cause, the shuttle’s wing leading edge was constructed from reinforced carbon-carbon (RCC) panels requiring exceptionally precise installation. The mounting brackets, connectors, and impact-resistant surface design in the damaged area all fell short of the highest standards.

CNC machining is essential for ensuring the structural integrity, dimensional accuracy, and precise geometric tolerances of these components.

Key Applications and Challenges of CNC Machining in Aerospace

Past incidents clearly demonstrate the critical importance of CNC precision manufacturing. Consequently, CNC-machined parts are now ubiquitous in aerospace component production:

Examples of CNC machined aircraft parts

Engine Components: Turbine blades, blade disks, and combustion chamber assemblies owe their complex curved geometries to 5-axis CNC machining. These parts are milled from solid metal blocks, ensuring structural integrity, safety, and exceptional precision. This enables them to withstand extreme environments and maintain functionality even under unexpected conditions.

Airframe Structures and Skin: Major structural components like the fuselage skeleton, wing spars, and connectors—some made of aluminum alloys, others of titanium alloys—are CNC-machined to achieve both lightweight and robust properties.

Landing Gear System: Precision landing gear components endure immense impact forces during landing. These parts are primarily fabricated from high-strength steel or titanium alloys, achieved through CNC machining.

Avionics Enclosures and Mounts: Sensitive electronic components within avionics require enclosures and mounts capable of withstanding shock and vibration to ensure reliable operation—a capability realized through CNC machining.

Challenges of high-precision CNC machining industry

As aircraft structural designs grow increasingly complex and incorporate various detection equipment, weight inevitably increases. Consequently, CNC machining faces significant challenges in aerospace applications:

Difficult-to-Machine Materials require high standard dimension

To meet additional performance requirements, materials like titanium alloys and nickel-based superalloys incorporate other metallic elements, significantly increasing hardness and making CNC machining considerably more difficult and time-consuming.

Multi-axis program experience requirements and talent shortage

Multi-axis machining path optimization is complex and prone to errors, demanding advanced programming expertise. The industry also requires a steady influx of young talent to sustain CNC machining operations.

Future CNC machining trends

To prevent future issues, aerospace manufacturing standards will inevitably tighten. Future CNC machining trends are projected to evolve as follows:

Smart Manufacturing and Industry 4.0: Integrating AI, big data, and IoT to enable self-optimizing production processes and predictive maintenance, enhancing component reliability.

Hybrid Manufacturing: Combining additive manufacturing (3D printing) with subtractive manufacturing (CNC machining) to enhance efficiency in producing complex components.

Integrated Materials Science and Processing: Developing specialized CNC machining methods for new materials like ceramic matrix composites and carbon fiber-reinforced composites.

In summary, CNC machining serves as the cornerstone of aerospace industry development. Its role in ensuring component precision, reliability, and flight safety is paramount. Failure of any machined part can lead to mission failure.

Ending of Cnc machining aerospace guide

Summary of Cnc machining aerospace guideIf you have component design or production plans for aerospace equipment or aircraft, contact WELDO for the latest quotes. Alternatively, email our customer service team to learn about the capabilities and manufacturing standards of our WELDO precision machining facility.