Precise machining manufacturer

Aluminum | Copper | Bronze | Stainless Steel | Magnesium | Titanium | Plastic etc.

Fast Prototype to Bulk production

One-stop service from prototype to production

Customer service and engineers work closely together to swiftly transform drawings into prototype samples right before your eyes.

Weldo Precision designs according to your usage requirements, selects materials, provides rapid quotes, and handles prototype sampling—ensuring comprehensive control over precision, speed, and quality to give your component production a head start.

Weldo Precision has manufactured custom components to the satisfaction of customers in over 125 countries and regions worldwide.

Precision machining manufacturer service

With our own precision machining industrial park in Dongguan and a network of carefully vetted raw material suppliers across China,

we offer comprehensive services ranging from CNC machining to injection molding, sheet metal fabrication, and 3D printing.

From rapid prototyping to high-precision standardized mass production, we are your trusted partner in China.

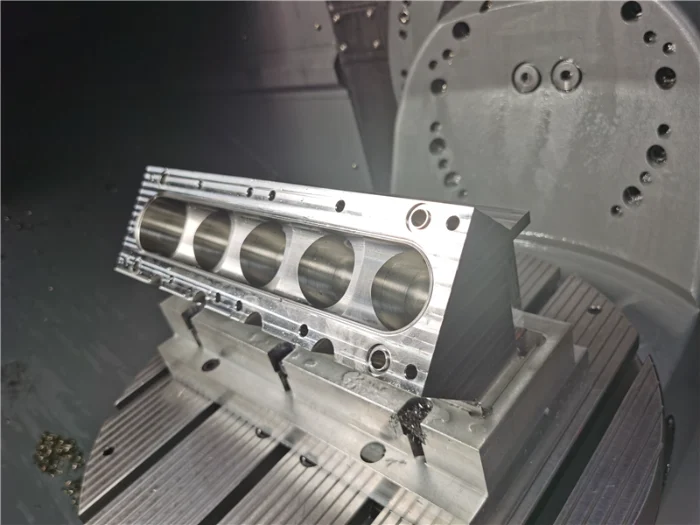

CNC machining service

CNC milling, turning, and other precision machining for prototypes and mass-produced parts. 0.002mm standard deviation, 1-3 day lead time.

Wire EDM

Sinker EDM and fast/medium speed wire cutting: sharp inside corners and thin walls. Smooth micro-machining with a kerf of 0.001-0.02 inches. Suitable for workpieces that cannot be touched or are less susceptible to stress.

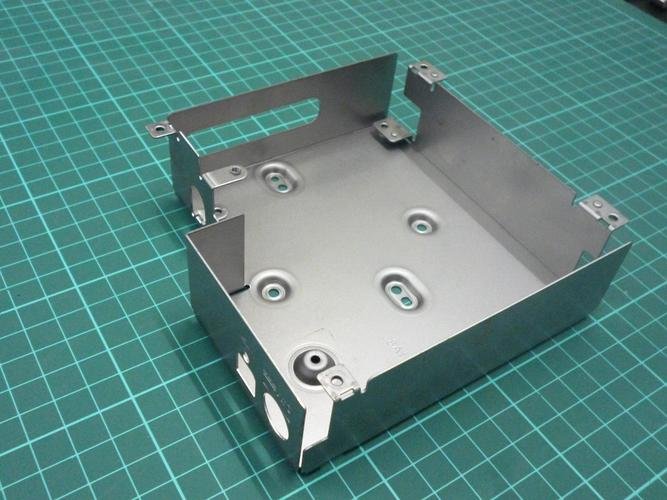

Metal sheet fabrication

Through laser cutting, bending, and welding, we can turn sheet metal prototypes into finished products within 1-4 days.

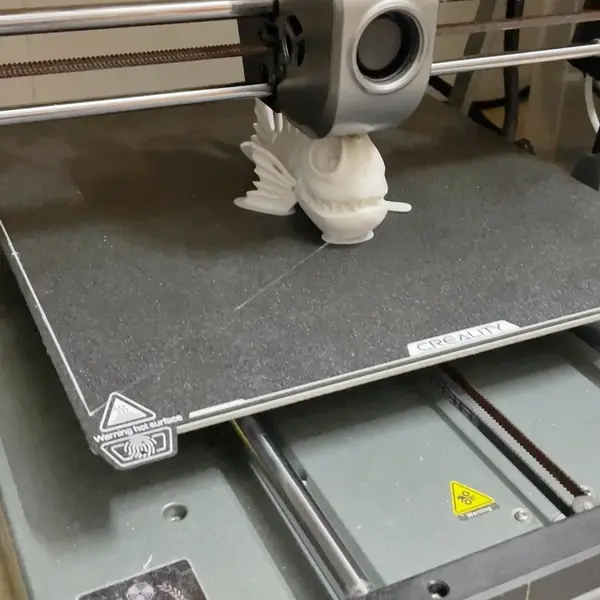

3D printing

PLA,ABS,PETG,NYNON,PEEK,TPU,ULTEM,RESIN,For fast production of prototypes/models for testing. Accuracy up to 0.009 inches. Delivery within 1-2 days.

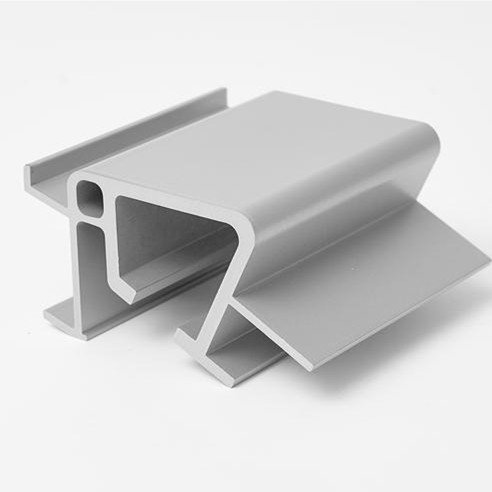

Metal extrusion service

Fast batch production of metal structural parts, delivery within 2-5 days, and more processing options can be provided

Die casting service

Large quantities of aluminum/zinc/magnesium/copper/alloys/stainless steel. 0.02 inch tolerance, 500+ unit batches.

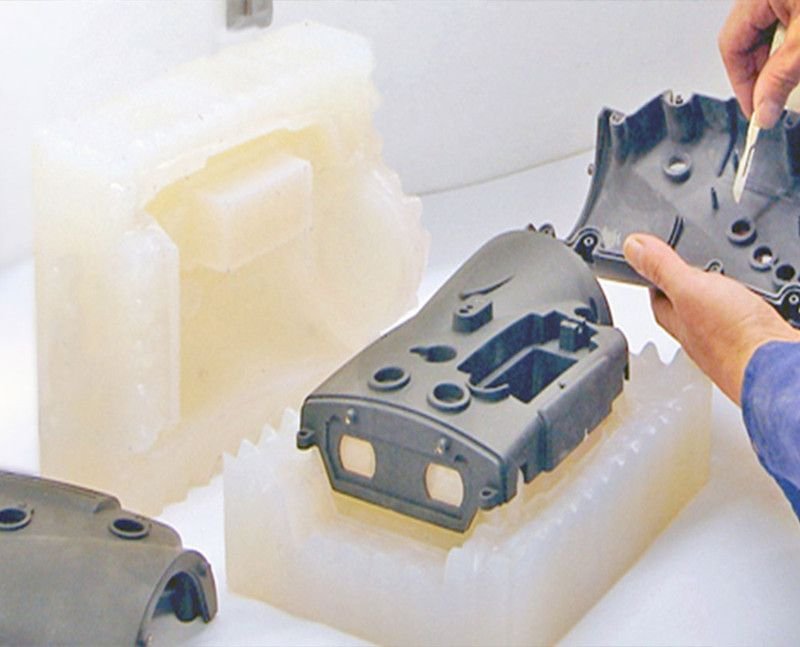

Vacuum casting

Plastic prototype production: Accuracy of ±0.002″, 15 parts can be completed in as fast as 10 days. Accelerate the production speed of your plastic parts and enhance brand competitiveness.

Injection molding

A professional team of engineers helps to quickly design mold production, with a minimum order quantity of 10 units

Reliable CNC Machining Partner in China. Fast machining manufacturer

Weldo is located in Dongguan City, Guangdong Province, China. We employ over 50 professional engineers and inspection personnel with extensive experience in the CNC machining industry (our longest-serving employee has 15 years of experience). Our machining centers,From manual milling (turning) machines to CNC machining centers (3-axis, 4-axis, 5-axis), along with high-speed, medium-speed, and slow-speed wire EDM machines, our mature manufacturing system enables rapid and precise part fabrication services tailored to your requirements.We also offer global shipping services, with deliveries to North America and Europe arriving in as little as 3-5 days.

How to cooperate with WELDO Precision

Quotation Cost Accounting

Select materials, receive accurate quotations and production feasibility assessments along with adjustment recommendations based on processing steps and order quantities, then place the order.

Shipping

Measure and compare part dimensions against the original drawings, conduct quality inspection, then ship.

One-stop service solution for new parts development

Weldo provides full-cycle product manufacturing solutions from drawing prototyping to mass production and reliability packaging, helping creative companies around the world to bring products/improved parts to market more safely and quickly.

Design on Demand

From initial production concepts to design based on customer needs, Weldo can accurately and quickly transform customer design concepts (design drawings) into reliable, high-quality prototypes.

Preliminary Design (optional)

Based on a rough sketch of the concept design, supplement with renderings and rough appearance parameters.

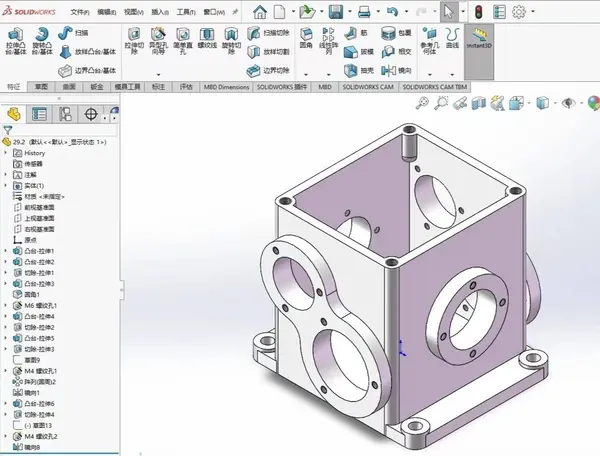

Mechanical Structure

Detailed structural parameters are determined, and 2D/3D drawings and engineering documents are created for further structural adjustments.

Design

Materials, colors, and processing techniques are planned, ensuring quality, appearance, and functionality meet customer requirements.

Cost Estimation

Production costs are calculated based on the required raw material size and process difficulty.

Prototype production & standard production testing

Our experienced team of engineers and high-standard quality control personnel work closely together to quickly transform drawings into high-quality structural parts.

Manufacturing plan

Select the most suitable materials, optimize the structure, and optimize the production process.

Assembly testing

Optimize process details and generate summary documentation based on customer assembly requirements.

Small-batch standardized production

Perform small-batch standard production testing according to the summarized production specifications, laying the foundation for subsequent large-scale production.

Optimization and mass production

Leveraging years of production experience, we successfully integrate reliable suppliers and transparently manage our factories and logistics personnel from procurement, production, quality inspection, packaging, and inventory.

Reliable Raw Material Supply Chain

We regularly conduct comprehensive supplier assessments and maintain partnerships.

Raw Material Procurement and Testing

We regularly develop procurement plans and conduct professional quality inspections.

Production Technical Support and Improvement

We provide further optimization solutions across the entire production chain to improve large-scale production efficiency, address production deficiencies, and enhance product quality.

Time and Cost Control and On-Time Delivery

We rationalize order scheduling, ensure orderly processing according to factory production schedules, estimate further costs, and ensure safe packaging and delivery.

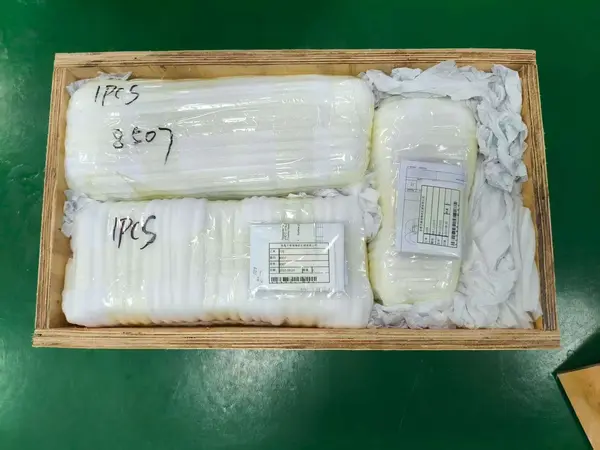

Safe packaging

We can help you design safe and effective product packaging to keep your goods safe and maximize space utilization.

Packaging Design

We create 2D/3D packaging drawings based on your product design.

Reliable Packaging Suppliers

We regularly evaluate the quality and expertise of our packaging suppliers based on the current situation and make adjustments as necessary.

Packaging

We procure packaging and raw materials, test packaging materials, and securely pack the goods, followed by final inspection.

Custom Manufacturing: Balancing Cost and Quality

Weldo has a team of over 60 quality engineers. To achieve a 95% production yield rate, we carefully plan before production, collaborate with multiple parties during the production process, and meticulously test prototypes with professional quality inspectors. Furthermore, our ISO 9001-2015-certified processes meet international standards for industrial equipment manufacturing.

Reliable Inspection Equipment

Our production facility features over 20 inspection tools, including projectors, height gauges, coordinate measuring machines (CMMs), 2D measuring machines, XRF analyzers, gauges, micrometers, and vernier calipers. These tools ensure that the products we ship to our customers meet dimensional standards and meet detailed specifications.

Professional Inspection Reports

We can provide prototype inspection documentation, RoHS certificates, and detailed dimensional and functional testing feedback for each processed component.

Complete Certification Documentation

WELDO holds ISO 9001:2015, CE, and FCC certifications, enabling us to undertake manufacturing projects for industries with stringent quality and safety requirements, such as aerospace, automotive, consumer electronics, and medical devices.

FAQ of precision machining manufacturer

Metals: Stainless steel (304/316L), titanium alloy (Ti-6Al-4V), aluminum alloy (7075/6061), nickel-based alloy (Inconel 718), copper alloy (C36000), etc.

Plastics: PEEK, PPS, PTFE, nylon (PA66), polycarbonate (PC);

Composites: Carbon fiber reinforced plastic (CFRP), ceramic matrix composite (CMC).

For high-temperature alloys or carbides, we use diamond-coated tools and cryogenic cooling technology to avoid work hardening. For example, the surface roughness of an Inconel turbine blade machined for an aircraft engine customer reached Ra 0.4μm.

Design Support: Perform design for manufacturing (DFM) analysis using SolidWorks/UG to optimize the structure and reduce manufacturing costs;

Prototyping: Rapid proofing within 3 days, supporting small-batch trial production (10-100 pieces);

Mass Production: Automated production lines achieve a daily capacity of over 5,000 pieces, equipped with in-line inspection systems (such as Keyence laser sensors);

Post-Processing: We offer surface treatments such as anodizing, electroplating, sandblasting, and laser engraving, and support assembly testing (such as airtightness testing).

A medical client previously used this service to reduce their catheter connector development cycle from 8 weeks to 3 weeks.

Equipment Calibration: All CNC machine tools undergo monthly laser interferometer calibration to ensure positioning accuracy of ±0.002mm;

Process Control: We utilize SPC statistical process control to monitor cutting forces, vibration, and other parameters in real time;

Inspection Standards: We perform first article inspection (FAI), patrol inspections, and final inspections in accordance with AS9100D (Aerospace) or ISO 13485 (Medical) requirements;

Traceability System: Each part is assigned a unique QR code that records information such as processing time, operator, and inspection data.

For example, we have produced vacuum chambers for a semiconductor equipment customer with a zero-defect record of 100,000 units.

Prototypes: 3-5 business days;

Small batches (100-1000 pieces): 7-15 business days;

Large batches (>1000 pieces): By negotiation, partial delivery is possible.

MOQ: No hard limit, with a minimum order of 1 piece. For complex parts (such as five-axis machining), a minimum of 10 pieces is recommended to spread the programming costs.