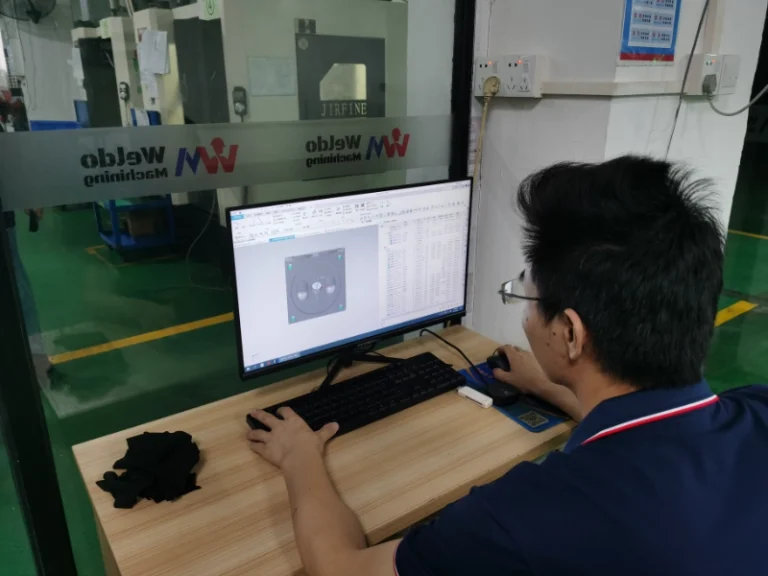

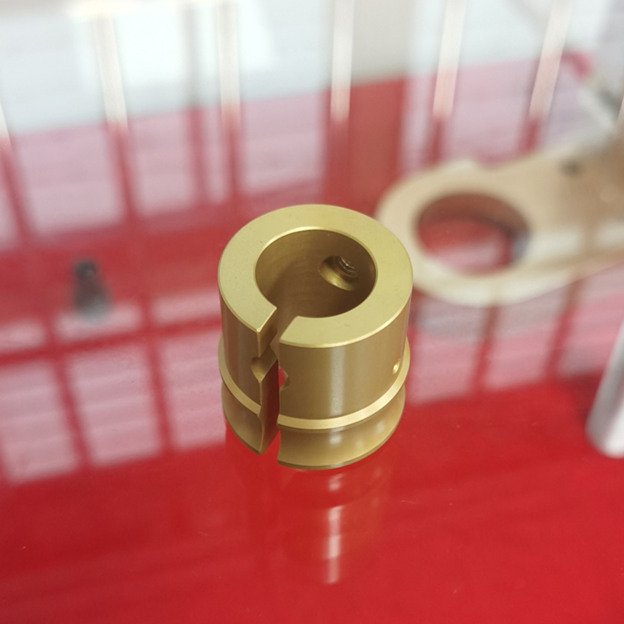

CNC machining bronze

CNC Machining Bronze refers to the process of using computer numerical control (CNC) technology to perform precision cutting, milling, drilling, turning, grinding, and other machining operations on bronze materials. This ultimately produces bronze components or products that meet the requirements of the design drawings (size, tolerance range). Bronze is an alloy of copper and tin (Sn), with certain types incorporating elements like lead (Pb), zinc (Zn), and phosphorus (P) to adjust properties. The automation and high precision advantages of CNC machining make it one of the core processes commonly used in mechanical manufacturing, precision instrumentation, aerospace, and other fields.

Price : 15-70 USD / PCs

Min wall thickness : 0.5mm

Tolerances : 0.001 mm

Max workpiece part : 2000mm*1000mm*1000mm

Other type bronze available in Weldo : Tin bronze,Aluminum bronze, bearing bronze, lead-tin bronze(C952,C932,C642,C863)

Physical Properties of Different CNC Bronze Alloys part

Tensile Strength, Fatigue Strength, Elongation at Break, Hardness, Density.

| Material | Grade | Tensile Strength | Fatigue Strength | Elongation | Hardness | Density | Notes |

|---|---|---|---|---|---|---|---|

| Tin Bronze | CuSn10 (GB/T 5231) | 310-550 MPa | 120-180 MPa | 10%-40% | 65-110 HB | 8.7-8.9 g/cm³ | 9%-11% Sn, Cast |

| CuSn6 (ASTM B103) | 280-480 MPa | 110-160 MPa | 15%-45% | 60-100 HB | 8.6-8.8 g/cm³ | 5%-7% Sn, Annealed | |

| Aluminum Bronze | CuAl10Fe3 (GB/T 5231) | 650-850 MPa | 250-320 MPa | 5%-15% | 180-240 HB | 7.5-7.8 g/cm³ | 9%-11% Al, Forged |

| CuAl11Ni6Fe5 (ASTM B150) | 750-950 MPa | 280-350 MPa | 3%-10% | 200-260 HB | 7.6-7.9 g/cm³ | 10%-12% Al, Quenched | |

| Bearing Bronze | CuSn10Pb1 (GB/T 1176) | 280-450 MPa | 100-150 MPa | 8%-25% | 60-95 HB | 8.6-8.8 g/cm³ | 9%-11% Sn, 0.5%-1.5% Pb |

| CuPb15Sn8 (ASTM B22) | 220-350 MPa | 80-130 MPa | 15%-30% | 50-80 HB | 8.5-8.7 g/cm³ | 14%-16% Pb, 7%-9% Sn | |

| Lead-Tin Bronze | CuSn5Pb5Zn5 (GB/T 5231) | 250-400 MPa | 90-140 MPa | 12%-35% | 55-90 HB | 8.4-8.6 g/cm³ | 4%-6% Sn, Pb, Zn |

| CuSn10Pb5 (ASTM B505) | 300-500 MPa | 110-170 MPa | 10%-30% | 70-105 HB | 8.7-8.9 g/cm³ | 9%-11% Sn, 4%-6% Pb |

Surface finishes for cnc machining bronze

Bronze inherently possesses excellent corrosion resistance and generally requires no surface treatment. However, to further enhance its durability or meet aesthetic and functional requirements, we at Weldo offer services such as sandblasting, electrolytic polishing, painting, electroplating, and chemical coating.

| Process | Description |

|---|---|

| As machined | After CNC milling, turning, grinding, and other machining processes, the original surface condition is maintained. |

| Polishing | Abrades the surface to smoothness and luster, eliminating scratches and enhancing reflectivity. Ra ranges from 0.025–0.1 µm |

| Sand blasting | Uses high-speed abrasive jets (e.g., quartz sand) to create uniform rough/matte textures, removing oxides or improving coating adhesion. |

| Tumbling | Rotates parts with abrasives in a drum to deburr, round edges, and refine surfaces, ideal for small-batch parts. |

| Electropolish | Removes micro-protrusions via electrolysis for a bright, smooth surface; boosts corrosion resistance, used for stainless steel precision parts. |

| Alodine | A chemical conversion coating for bronze, forming an oxide layer to enhance corrosion resistance and aid paint adhesion. |

| Heat treatment | Alters material structure via heating/cooling to improve hardness/strength (e.g., quenching), no direct appearance change. |

| Black oxidize | Forms a black oxide film on bronze workpiece for rust prevention, decoration, or reducing glare; thin, minimal size impact. |

| Electroless Nickel | Deposits a uniform nickel layer via chemical reaction (no electricity), wear/corrosion-resistant, controllable thickness. |

| Chrome Plating | Electrolytically deposits chromium; decorative chrome (bright) or hard chrome (wear-resistant), used for auto parts, sanitary ware. |

| Powder Coating | Electrostatically applies dry powder, cured at high temperature for a tough, color-varied coating; wear/corrosion-resistant. |

| Brushed Finish | Rubs the surface in one direction to create continuous fine lines; decorative and wear-resistant, used for bronze appliances. |

Pros and Cons of Bronze CNC Machining

Pros

1. Good machinability: Bronze is relatively soft, with low cutting resistance. It causes less tool wear and suits complex-shaped parts.

2. Excellent wear resistance: Tin-containing bronze has moderate surface hardness, making machined parts ideal for friction components like bearings and gears.

3. Strong corrosion resistance: Better than ordinary steel in air, seawater, etc., suitable for outdoor or humid environments.

4. Good thermal and electrical conductivity: Retains bronze’s inherent properties, fit for heat-dissipating or conductive parts.

5. High dimensional stability: Minimal post-machining deformation, ensuring high precision for precision parts.

Cons

1. High material cost: Bronze is more expensive than steel, aluminum, etc., leading to cost pressure in mass production.

2. High density: Machined parts are heavy, which may increase overall equipment weight—unsuitable for lightweight needs.

3. Limited machining efficiency: Though easy to cut, high-hardness bronze alloys (e.g., aluminum bronze) may cause tool adhesion during high-speed machining.

4. Surface treatment limitations: Some bronze alloys have average post-machining gloss; extra polishing is needed for high decorativeness.

5. Poor weldability: Harder to weld than steel or aluminum; mechanical joining is preferred for assembly after machining.

Application Fields of CNC Machining Bronze Parts

Due to bronze’s excellent corrosion resistance, durability, and chemical stability, we frequently manufacture CNC machined components for our clients. Below are the primary application areas:

Industrial Machinery and Transmission Sector: Leveraging bronze’s wear resistance and low friction coefficient, primarily producing sliding bearings, gears, worm gears, and hydraulic valve spools.

Marine Engineering and Shipbuilding Sector: Utilizing bronze’s resistance to salt and alkali corrosion, primarily manufacturing components for ship propulsion systems, marine instrument accessories, and port machinery parts.

Aerospace Sector: Bronze’s high-temperature resistance, electrical conductivity, moderate strength, and corrosion resistance enable production of valve bodies, conduit fittings, bronze waveguides, and precision bushings.

3C Electronics Sector: Bronze’s thermal and electrical conductivity facilitates manufacturing of signal connectors for high-end instruments, conductive terminals for circuit boards, protective housings for sensors, heat sinks for chips, and thermal pads.

Medical Equipment Sector: Medical bronze alloys offer biocompatibility for prosthetic joint connectors, CT machine guide rails, positioning components in diagnostic instruments, and dental handpiece bearings.

Artistic and Vintage Processing: Bronze’s textured finish and antique decorative appearance are utilized primarily in bronze carvings, bronze handles, clock gears, valve cores for wind instruments, and key shaft sleeves.

FAQ about CNC Machining Bronze Parts

Aluminum bronze: Commonly used for manufacturing heavy-duty mechanical parts demanding high strength and wear resistance, such as bearings and gears. Due to its high hardness, wear-resistant tools like carbide inserts are required.

Lead bronze: Demonstrates significant advantages when machining complex-shaped parts like hydraulic valve spools. Its outstanding chip-breaking properties reduce chip entanglement during CNC machining.

Thin-walled part deformation: Bronze's low rigidity makes thin-walled structures prone to vibration-induced deformation during machining. Solutions involve optimizing toolpaths (e.g., layered cutting), employing soft-clamping fixtures (e.g., rubber pads), and selecting low-cutting-force parameters.

Small hole or edge burrs: Bronze's ductility causes burrs on precision areas. Add post-processing steps like burnishing or laser deburring, paired with sharp, high-precision tools (e.g., high-helix micro drills).

Electropolishing: Improves surface smoothness and removes microscopic burrs. Suitable for precision instruments or decorative parts like musical instrument valves.

Tin or Nickel Plating: Enhances wear resistance and conductivity. Commonly used for bronze connectors or conductive contacts in electronic devices.

Blackening: Creates a black matte finish to meet aesthetic or anti-glare requirements, such as for vintage machinery or optical equipment components.

Streamline Process Flow: For non-critical surfaces with minimal decorative requirements, adopt a “machined raw surface” approach. Consolidate features into a single toolpath to shorten machining cycles.

Batch Production Planning: For small-batch orders (10–50 pieces), allocate setup time across multiple parts. For large-volume orders (>100 pieces), utilize high-speed CNC machines to boost efficiency and reduce unit labor costs.

Influencing Factors: Higher machine tool precision is preferable (positioning accuracy ≤ 0.003mm); utilize high-rigidity cutting tools to minimize vibration-induced deviations; promptly replace tools during machining to reduce error probability; control processing environment temperature (e.g., 20±2°C); avoid prolonged continuous machining of large components to mitigate thermal expansion issues.