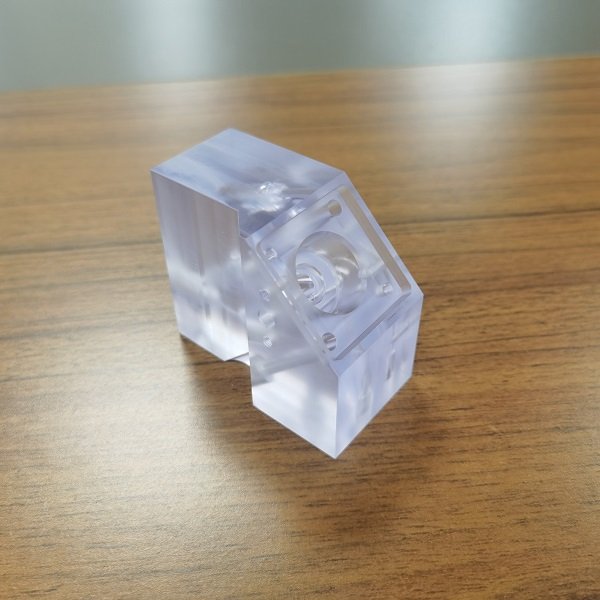

In the field of modern precision manufacturing, acrylic (PMMA) has become a widely used material in industries such as automotive, medical, and lighting due to its high transparency, excellent toughness, and ease of machining. Acrylic CNC machining, capable of meeting complex structural customization demands while ensuring consistency in mass production, has emerged as a crucial enabler for driving innovation in acrylic applications. Acrylic cnc machining guideline comprehensively explores the technical essentials and practical value of acrylic CNC machining through dimensions including material understanding, process characteristics, core advantages, and application scenarios.

What is Acrylic?

Acrylic, also known as polymethyl methacrylate (PMMA), is a common thermoplastic material renowned for its exceptional transparency and often referred to as “organic glass.” Unlike traditional inorganic glass, acrylic is significantly lighter—its density is only about half that of glass—and offers superior toughness and impact resistance, making it less prone to breakage. This material’s excellent machinability enables its widespread use across multiple industries, with acrylic CNC machining being one of the fastest and most efficient methods for producing precision components. Available in sheet, rod, and tube forms, acrylic can be CNC-machined into customized structural components tailored to specific application requirements.

Characteristics of Acrylic Material

Acrylic possesses a range of properties making it suitable for CNC machining and diverse industrial applications. First, it offers exceptional transparency with light transmittance exceeding 92%, surpassing some types of glass. This makes it ideal for parts requiring high clarity, such as display cases. Second, it possesses favorable mechanical properties—while not as hard as metals, its rigidity is sufficient for non-high-load components. Its high toughness also reduces cracking risks during CNC machining. Third, acrylic excels in weather resistance and UV protection, resisting yellowing and aging even under prolonged sunlight exposure, making it suitable for outdoor applications. Fourth, its chemical stability allows it to withstand most weak acids and alkalis, ensuring the longevity of CNC-machined parts. Additionally, acrylic is easily dyed, and dyed parts maintain their color without fading over time, further expanding its applications in decorative and appearance-oriented products.

What CNC Processing Techniques Are Suitable for Acrylic?

Acrylic (PMMA) can be processed through various techniques, each with distinct advantages and applications. The primary methods are outlined below:

(1) CNC Machining

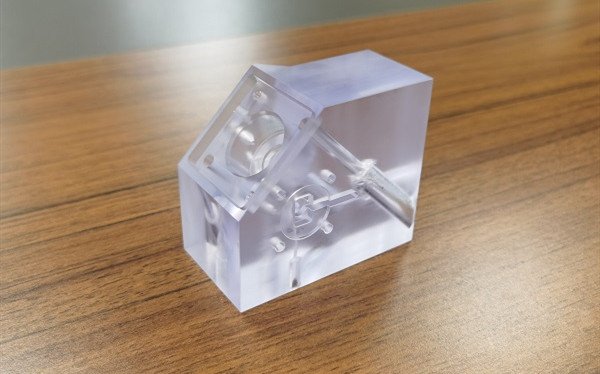

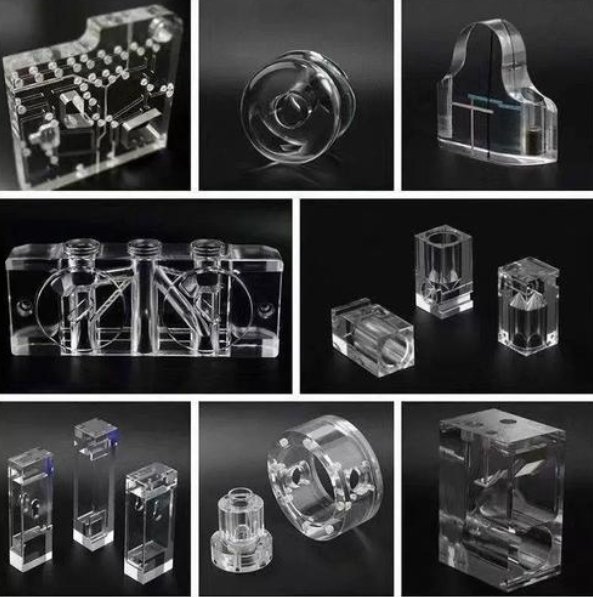

Acrylic CNC machining utilizes computer numerical control (CNC) machines to perform precision cutting, milling, drilling, and grinding on acrylic materials. This process excels at producing complex-shaped parts with exceptional accuracy—tolerances can be controlled within ±0.01mm, meeting the demands for precision components in industries such as medical devices and automotive. Acrylic CNC machining offers high flexibility, accommodating both small-batch custom orders and large-scale production. It eliminates the need for expensive molds and design time, reducing prototype development costs. Whether processing flat acrylic sheets or three-dimensional parts, optimized programming and appropriate tool selection ensure smooth surfaces and precise, uniform dimensions while minimizing material waste.

(2)Injection Molding

Injection molding is suitable for high-volume production of acrylic parts with lower precision requirements, such as acrylic lenses and everyday containers. The process involves injecting molten acrylic pellets into a mold, where they cool and solidify into the desired component. Compared to CNC machining, injection molding offers greater efficiency for large-scale production but requires mold design and fabrication, entailing higher upfront costs and time investment. Typically, injection molding becomes more cost-effective when production exceeds 10,000 units; for small batches or customized parts, acrylic CNC machining is more suitable.

(3) Acrylic Extrusion Molding

Extrusion molding is primarily used to produce acrylic products with continuous shapes, such as sheets, rods, tubes, and profiles. This process involves extruding molten acrylic through a die with a specific cross-sectional shape, cooling it to form the final product. Extruded acrylic products feature uniform thickness and stable properties, often serving as raw materials for CNC machining—for example, extruded acrylic sheets can be further processed into precision parts via CNC machining. This method efficiently produces standard-shaped raw materials, laying the foundation for subsequent precision machining.

(4) Acrylic Welding Techniques

Acrylic welding techniques are used to join multiple acrylic parts into a single structural unit. Common methods include solvent welding, hot-air welding, and laser welding.

Solvent welding softens the surface of acrylic parts using a special solvent, then bonds them together under pressure.

Hot-air welding melts the acrylic surface with heated air before fusing the parts. This technique is often applied after CNC machining, such as creating individual acrylic components via CNC processing and then welding them into larger products like display cases or machine housings. When executed properly, welded acrylic parts maintain excellent transparency and structural integrity.

(5) Acrylic High-Temperature Fusion

Acrylic high-temperature fusion is a process that melts and shapes acrylic material using high heat, commonly used to create curved or irregularly shaped acrylic products. Unlike CNC machining, which shapes material by removal, thermal forming is a “shaping” process. It involves bending or molding heated acrylic into desired forms, making it suitable for products like curved acrylic panels and decorative arches. However, this process offers lower precision than CNC machining and is primarily used for parts with high aesthetic requirements.

What Are the Advantages of Using Acrylic CNC-Machined Parts?

Leveraging the precision and flexibility of CNC machining, acrylic CNC-machined parts are widely favored across multiple industries.

First, they offer high precision and excellent consistency. CNC machining relies on computer programs to control machine tools, eliminating human operational errors. This ensures near-perfect dimensional consistency across every batch of parts—a critical requirement for applications demanding assembly accuracy, such as automotive dashboards and medical device components. Second, it enables complex shape machining. Unlike some traditional processes limited to simple structures, acrylic CNC machining handles intricate designs like hollow patterns, multi-step grooves, and precision holes, meeting innovative product requirements. For example, in lighting fixtures, CNC-machined acrylic lampshades with complex patterns enhance light diffusion. Third, it offers short processing cycles. For small-batch production or prototyping, acrylic CNC machining eliminates the need for mold preparation. After completing CAD design, inputting the program (G-code) into the CNC machine initiates processing. Typically, a batch of small parts can be completed within hours to a day, accelerating product development and time-to-market. Fourth, it delivers superior surface quality. Acrylic parts processed via CNC machining feature smooth surfaces with minimal burrs. Simple post-processing (e.g., polishing) achieves high gloss while preserving the material’s inherent transparency. This eliminates the need for additional coatings or painting, reducing production steps. Fifth, controllable material utilization. Through optimized programming in acrylic CNC machining (such as efficient nesting of parts on acrylic sheets), raw material waste can be minimized. For higher-cost specialty materials like flame-retardant acrylic, this advantage significantly reduces production costs.

What are the application fields for CNC-machined acrylic parts?

Leveraging the precision and versatility of CNC machining, acrylic parts find extensive use across multiple industries. Specific application scenarios include:

(1) Automotive and Motorcycle Accessories Industry

In this sector, CNC-machined acrylic produces components like dashboard covers, LED light housings, and decorative trim strips. Acrylic’s high transparency ensures clear visibility for instrument panel covers, enabling drivers to read data effortlessly. Its impact resistance guarantees component durability during vehicle operation. CNC machining achieves precise dimensions compatible with other automotive parts, ensuring gap-free and misalignment-free integration. For instance, CNC-machined acrylic lamp housings for motorcycles can be custom-shaped to match vehicle models, balancing functionality and aesthetics.

(2) Lighting Fixtures Industry

The lighting fixtures industry represents a primary application market for CNC-machined acrylic components. Through CNC processing, acrylic can be formed into lampshades, diffusion panels, and lamp bases featuring diverse patterns and shapes. Acrylic’s excellent light transmission ensures uniform illumination distribution, while its colorability enables the creation of colored lampshades to cultivate distinct lighting atmospheres. For instance, in indoor lighting, CNC-machined acrylic diffusion panels with micro-patterns soften harsh light to protect vision. In outdoor lighting (e.g., street lamps), CNC-machined acrylic components offer strong weather resistance for long-term stable operation.

(3) Medical Devices

In the medical device sector, CNC-machined acrylic is essential for producing precision components such as transparent covers for diagnostic equipment, housings for surgical instrument sets, and test tube racks. Acrylic’s chemical stability prevents reactions with medical reagents, ensuring accurate test results. The high precision of CNC-machined acrylic meets stringent tolerance requirements for medical devices—for instance, blood cell analyzer covers require ultra-flat surfaces to maintain optical detection accuracy. Additionally, acrylic’s ease of cleaning and sterilization complies with healthcare hygiene standards.

(4) Construction Industry

In construction, CNC-machined acrylic parts serve decorative components, transparent partitions, and signage. CNC processing transforms acrylic sheets into ornamental wall panels, ceiling fixtures, and other shapes that lend modern aesthetics to buildings. Transparent acrylic partitions are lighter and easier to install than glass, making them ideal for offices and retail spaces. Text and patterns on acrylic signage produced via CNC machining offer high precision, durability, and fade resistance, remaining clearly visible even in outdoor environments.

How to Improve Workpiece Utilization and Machining Precision in Acrylic CNC Processing?

Enhancing workpiece utilization and machining precision is key to optimizing the efficiency and quality of acrylic CNC processing. This approach reduces costs while boosting brand competitiveness in the market.

(1) Improving Workpiece Utilization

Optimize nesting design: Utilize specialized nesting software to arrange multiple parts on a single sheet of acrylic. The software automatically calculates the most compact layout, minimizing gaps between components. For instance, when machining small acrylic assemblies, software nesting increases the number of parts per sheet by 15%-30% compared to manual nesting, directly enhancing material utilization.

Recycle Scrap Material: Collect acrylic scraps generated during CNC machining, sorting them by size and thickness. Reuse these scraps as raw material for small parts or prototypes to minimize waste. For instance, scraps unsuitable for large components can be machined into small parts like acrylic spacers or washers.

Select Appropriate Material Sizes: Choose acrylic sheets or rods matching the final part dimensions to avoid using oversized materials for small components, preventing unnecessary waste. For instance, when machining a 50mm×50mm acrylic part, using a 60mm×60mm sheet is more efficient than a 100mm×100mm sheet in CNC processing.

(2) Enhancing Machining Precision

Regularly calibrate CNC machines: Before initiating acrylic CNC machining, calibrate the machine’s positioning accuracy and spindle speed, while inspecting tool wear and length. Use precision measurement tools like dial indicators or laser interferometers to check and adjust machine parameters. Regular calibration ensures sustained precision and minimizes deviations from prolonged use.

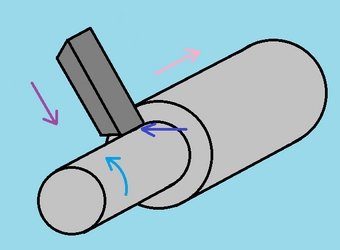

Select appropriate tools: Use tools specifically designed for acrylic. Sharp carbide tools are ideal as they minimize friction and heat generation during cutting. Dull tools or those intended for metals can cause acrylic to melt or crack, compromising precision. For example, employing end mills with high helix angles in acrylic CNC machining improves chip evacuation and reduces the risk of dimensional errors caused by chips adhering to the workpiece.

Optimize cutting parameters: Adjust spindle speed, feed rate, and cutting depth based on acrylic thickness and hardness. For thin sheets, use lower feed rates and shallower depths to prevent vibration. For thicker sheets, higher spindle speeds can boost efficiency without compromising precision. For example, when machining 10mm-thick acrylic, setting the spindle speed to 10,000-15,000 rpm and feed rate to 500-800 mm/min in acrylic CNC machining balances efficiency and precision.

Use high-quality fixtures: Secure acrylic material with fixtures featuring soft clamping surfaces (e.g., rubber pads) to prevent deformation or displacement during acrylic CNC machining. Fixtures must align with the machine coordinate system to ensure precise workpiece positioning. For instance, vacuum cups evenly distribute clamping force when securing acrylic sheets, preventing localized deformation that compromises accuracy.

Conclusion of this article

Acrylic has become a critical material across numerous industries due to its exceptional transparency, impact resistance, and machinability. Acrylic CNC machining is the core technology unlocking its application potential. This guide covers acrylic fundamentals, machining processes, advantages of CNC-machined acrylic parts, application fields, and methods to enhance machining efficiency and precision. Whether you operate in automotive, lighting, medical, or construction industries, acrylic CNC machining delivers customized, high-precision parts tailored to your specific requirements. For any acrylic CNC machining needs—including prototype development, small-batch customization, or mass production—contact Weldo for a detailed quote. Our professional team will tailor the most suitable acrylic CNC machining solution for you, ensuring both product quality and cost-effectiveness.