If you’re new to the precision machining industry, you might wonder: What is the CNC machining per hour cost? However, this figure isn’t a fixed “one-size-fits-all” price. It’s determined by both your design drawings and the company’s capabilities, encompassing factors like drawing complexity, material type, precision requirements, quantity, the CNC machine setup chosen by the factory, material costs, material waste, packaging, and shipping fees. Prices can vary significantly across different projects and service providers. Understanding these variables is crucial for effective budget planning, supplier negotiations, and achieving cost reduction and efficiency gains in CNC machining services.

Key Factors Determining CNC Machining Hourly Costs

Before discussing average costs, let’s break down the core elements driving CNC machining hourly rates. These factors directly influence service providers’ pricing logic and can sometimes cause final hourly rates to fluctuate by over 50%.

1. Equipment Type and Complexity

The type of CNC equipment used is a primary cost influencer. Basic 3-axis CNC milling machines or lathes (primarily handling simple parts requiring linear cutting) typically have lower hourly CNC machining costs than advanced 5-axis equipment. 5-axis CNC equipment enables multi-axis rotation of parts (e.g., in Haas precision machining, the A-axis rotates the base while the C-axis rotates vertically on the side), facilitating complex geometries. However, such equipment demands more advanced technical support, higher maintenance costs, and greater operator skill, consequently driving up hourly rates.

2. Labor Costs

Skilled CNC operators and programmers are essential for achieving precise, efficient machining, and their expertise inevitably carries a cost. Regions with higher living costs (e.g., North America, Western Europe) typically command higher labor rates, directly inflating CNC machining hourly costs. Conversely, areas with lower labor costs (e.g., certain Asian countries, Eastern Europe) may offer lower hourly rates. However, a balance between “cost” and “quality” must be considered: inexperienced operators may cause machining errors, rework, or material waste, ultimately increasing overall project expenses.

3. Material Costs

Although material costs are typically billed separately from hourly machining fees, they indirectly influence the hourly cost of CNC machining. Harder or more specialized materials (such as titanium alloys, Inconel alloys, carbon fiber) require specialized cutting tools, lower cutting speeds, and more frequent tool changes. This reduces the hourly machining efficiency of the equipment.Therefore, service providers may charge higher hourly rates to compensate for longer machining times and additional tool wear. Softer materials like aluminum and plastic, however, can be machined faster, resulting in lower hourly costs for CNC machining.

4. Tooling and Maintenance Costs

CNC equipment relies on high-precision tools (such as end mills, drills, and inserts), which wear down over time and require periodic replacement. Specialized tools for unique machining scenarios are typically factored into hourly rate calculations. Additionally, regular maintenance—including calibration, lubrication, and component replacement—is essential to maintain CNC machining accuracy. Service providers allocate these ongoing expenses across the equipment’s operational hours, reflecting them in the CNC machining hourly cost to maintain optimal machine performance.

5. Operational and Facility Costs

Rent, utilities, insurance premiums, and design software (e.g., CAD/CAM programs for part design) constitute operational overhead (indirect costs). These costs are allocated across the equipment’s actual operating hours. Consequently, larger factories or businesses utilizing cutting-edge software may charge slightly higher hourly rates for CNC machining to cover these indirect expenses. Smaller workshops with lower operational costs may offer more competitive pricing, but such facilities typically operate fewer machines and have limited capacity for large-scale projects or high-precision requirements.

CNC machining per hour cost: Actual Market Range Reference

Having understood the influencing factors, what is the actual hourly cost range for CNC machining? Below is a general range categorized by equipment type and region, though note this represents only averages—specific project costs may fall above or below this range.

• Basic 3-axis CNC machining: Rates typically range from $20–50/hour in low-labor-cost regions. In high-labor-cost regions, expect $50–100/hour. This equipment is suitable for machining simple parts like brackets, housings, and shafts.

·4-Axis CNC Machining: Adding a rotary axis (e.g., rotary table) enables more complex cutting operations. In low-cost regions, CNC machining costs $60–120 per hour; in high-cost regions, $100–150 per hour. Commonly used for multi-surface machining without part repositioning.

·5-axis CNC machining: As the most advanced type, 5-axis machines process precision parts (e.g., aerospace components, medical devices). In low-cost regions, CNC machining costs $80–180 per hour; in high-cost regions, rates reach $150–300 per hour (or higher). Higher fees stem from the equipment’s complexity, demanding operator skills, and its efficient turnaround for intricate parts.

·Specialized CNC Machines: Equipment tailored for specific applications (e.g., CNC waterjet cutting, laser cutting, EDM) exhibits greater rate variation. For instance, waterjet cutting may cost $40–100 per hour, while EDM for machining hard materials ranges from $70–200 per hour depending on location and machine size.

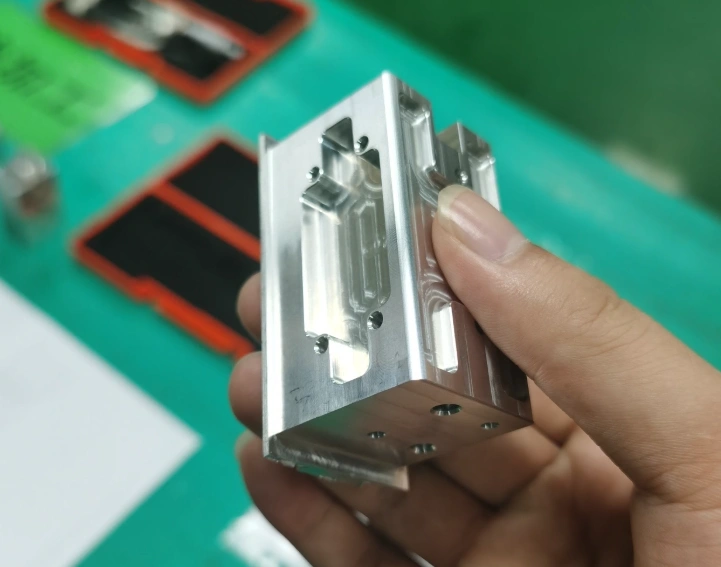

Weldo possesses over 20 years of expertise in CNC machining technology and cost control capabilities. Our pricing for machining costs on 3-axis, 4-axis, and 5-axis equipment is determined by comprehensively evaluating machine precision, material processing complexity, and process requirements. Below are several recent machining examples.

Weldo 3-Axis, 4-Axis & 5-Axis CNC Machining Cost Comparison Table

| Machine Type | Core Features | Material Cost Range (USD/Hour) | Typical Case Details | Case Hourly Cost (USD) | Key Advantage Data |

|---|---|---|---|---|---|

| 3-Axis CNC Machining | Focuses on linear cutting; suitable for parts with simple geometries | Aluminum alloy (easy to machine): 10-20; Stainless steel (medium hardness): 15-25 | 6061 aluminum alloy housing for electronics industry (120mm×80mm×30mm), requiring surface milling, drilling, and simple slot machining | 15 | Cutting speed up to 3000rpm; processes 8-10 pieces per hour; tool wear cost accounts for only 5% |

| 4-Axis CNC Machining | Additional 1 rotational surface machining capability; reduces clamping times and positioning errors | Brass: 18-25; 304 stainless steel: 25-35 | Brass gear for automotive parts (φ80mm×25mm), requiring 12 tooth slots and end face threads machining | 20 | Completes all processes in one clamping; 40% higher efficiency than 3-axis; unit cost 20% lower than multi-step machining |

| 5-Axis CNC Machining | Additional A-axis (base rotation) & C-axis (vertical side rotation) linkage; suitable for high-end complex parts (aerospace, medical) | Titanium alloy (Ti6Al4V): 40-50; Superalloy: 50-70 | Ti6Al4V blade for aerospace industry (200mm×120mm×80mm), with ±0.005mm surface tolerance; uses tungsten carbide coated tools | 55 | Cutting speed 800rpm; overall cost 30% lower than traditional multi-machine machining solutions |

How to Optimize Budgets and Reduce Hourly Costs for CNC Machining

To lower hourly CNC machining costs without compromising quality, consider the following strategies:

Simplify part design: Complex geometries (e.g., tight tolerances, deep cavities, sharp corners) increase machining time and require specialized tools. Simplifying designs without compromising functionality—such as adjusting tolerances to industry-standard ranges or incorporating rounded corners—enhances production efficiency and lowers hourly rates.

Select appropriate materials: Prioritize materials that balance “functional performance” with “machinability.” For instance, using aluminum alloy instead of titanium when it meets part requirements enables faster machining speeds, thereby reducing hourly CNC machining costs.

Batch production: Service providers typically offer lower hourly rates for high-volume orders. Machining 100 parts in one operation is more efficient than 10 separate runs of 10 parts each—reducing setup frequency, ensuring tool stability, and accelerating overall production.

Shop Around: Don’t settle for the first quote. Operational costs, labor expenses, and equipment capacity vary among providers. Comparing 2-3 quotes helps identify the most cost-effective hourly CNC machining solution.

Conclusion: Beyond the Hourly Rate

While understanding the “hourly cost of CNC machining” is crucial, it’s not the only factor to consider. Excessively low hourly rates may conceal risks: such as machining service providers potentially exceeding machining tolerances, using substandard materials, or delaying delivery times, ultimately leading to additional costs. Conversely, experienced suppliers with slightly higher hourly rates can save you long-term costs through faster delivery speeds, fewer rework cycles, and finished products that meet specifications.

When budgeting for CNC machining projects, we recommend thoroughly discussing project details with potential suppliers to understand their equipment capabilities, operator expertise, and quality control processes. Only by precisely aligning your requirements with a supplier’s strengths can you ensure reasonable value for the hourly cost of CNC machining while receiving high-quality finished products that drive business growth.

WELDO brings over 20 years of manufacturing expertise. Our in-house machining facility houses more than 50 3-axis machines, over 40 4-axis CNC machines, and over 20 5-axis CNC machines. We also operate high-speed wire EDM machines, grinding machines, and CNC lathes. medium-speed wire EDM machines, grinding machines, and CNC lathes. We have served clients from over 100 countries and regions, offering precision machining services for approximately 100 common materials including metals and plastics. Our minimum tolerance control reaches the micron level (0.001mm). If you have such requirements, contact our professional customer service team to obtain a machining solution and quote for your design. We can produce prototype samples in as little as one day, accelerating your product launch timeline.