What is CNC Plastic Machining ?

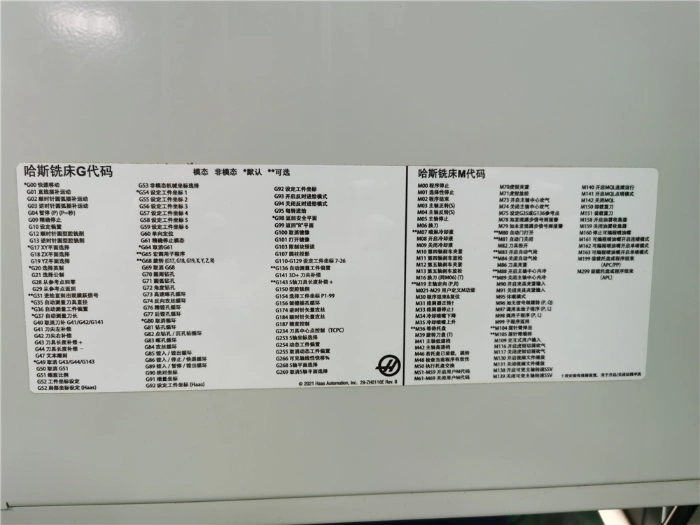

CNC plastic machining, fully known as Computer Numerical Control plastic machining, is a precision manufacturing technology that utilizes computer-programmed instructions to control automated machine tools for milling, turning, and cutting plastic materials. Unlike traditional manual processing, this technology does not require continuous human intervention during the machining cycle. Instead, it relies on pre-set computer program codes (G-codes and M-codes) to control tool path movements, achieving high precision and consistent machining results.The following is the relevant content of cnc plastic machining comprehensive guideline.

Its core principle involves converting two-dimensional or three-dimensional design data (typically in CAD format) into CNC code. This code drives machine components—such as cutting tools, spindles, work tables, and rotary axes—to move along multiple axes (commonly 3-axis, 4-axis, or 5-axis configurations). Based on the properties of plastic materials, operators select specialized cutting tools to remove excess plastic from raw material in a controlled manner. This process ultimately produces parts with precisely defined shapes and extremely tight tolerances—achieving tolerances as low as ±0.005mm in high-precision applications.

Whether producing simple plastic washers and gaskets or complex precision components for medical devices, aerospace plastic brackets, or display screen bezels—structures difficult to achieve through manual processing—CNC plastic machining delivers efficient solutions. It supports batch production with parts that fit seamlessly together, ensuring strong integrity. This has established CNC machining as a core technology in modern plastic manufacturing.

Why Choose CNC Plastic Machining ?

In plastic part manufacturing, CNC plastic machining effectively addresses the limitations of alternative processes like molded injection, extrusion molding, and 3D printing through its unique advantages in precision, efficiency, and adaptability, making it the preferred solution across numerous industries.

Ultra-High Precision for Demanding Tolerance Requirements

Industries like aerospace, medical, and electronics demand exceptional fit accuracy and operational stability from plastic components. Parts must integrate seamlessly with other assemblies or function reliably in high-risk, extreme environments. CNC plastic machining achieves tolerance control at ±0.01mm or even higher precision (minimum 0.005mm), depending on material and machine performance. For instance, plastic valve assemblies in surgical instruments for the medical field require precise control of fluid channel dimensions to prevent leakage from excessive tolerances—a core requirement consistently met by CNC plastic machining.

High Cost-Effectiveness for Small Batch Production

Injection molding and extrusion require expensive tooling upfront. While 3D printing eliminates tooling costs, it suffers from low batch production efficiency. CNC plastic machining requires no tooling investment and offers controllable costs from single-piece prototyping to small batches (tens to thousands of units). This significantly reduces upfront investment and shortens time-to-market for R&D-stage sample validation and customized part production (e.g., specialized electronic device housings).

Capable of Machining Complex Geometric Structures

Certain industry components feature intricate designs—including complex surfaces, hollow cavities, and deep recesses—that traditional methods struggle to replicate accurately. CNC plastic machining leverages multi-axis technology (e.g., 5-axis machining) to cut plastic blanks from multiple angles, effortlessly achieving complex geometries. For instance, aerospace plastic fairings require both lightweight construction and aerodynamic surfaces—CNC machining precisely replicates these intricate design specifications.

Wide Material Compatibility

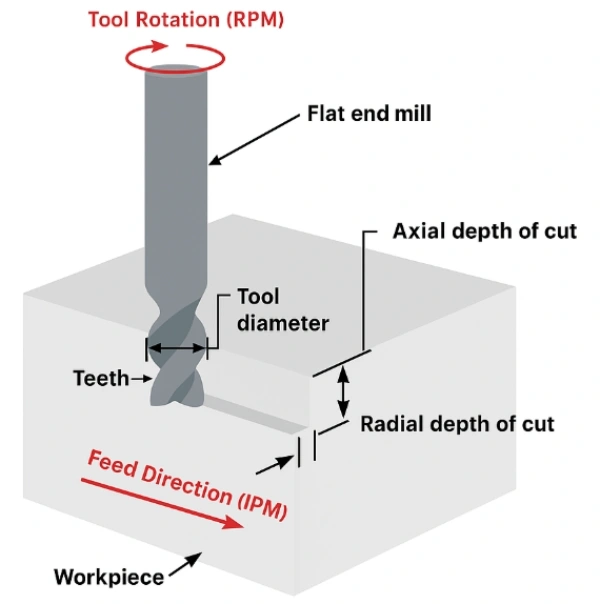

Whether processing high-hardness engineering plastics (e.g., PEEK, PC) or highly resilient elastomers (e.g., Nylon, TPE), CNC plastic machining achieves stable results by adjusting cutting parameters (spindle speed, feed rate, cutting depth) and tool size/type. This eliminates frequent equipment or process changes due to material properties, enhancing production flexibility.

Types of CNC Plastic Machining Services

CNC Plastic Milling

CNC plastic milling is a process that uses rotating milling cutters (end mills) to cut plastic workpieces, enabling the machining of structures such as flat surfaces, grooves, contours, holes, and complex curved surfaces. This process supports multi-axis interpolation (commonly 3-axis, 4-axis, or 5-axis) and can produce various parts ranging from simple plastic covers to complex medical instrument housings. For instance, in the electronics industry, the plastic heat sink chambers of routers are CNC-milled to precisely control chamber depth and inner wall smoothness, ensuring optimal heat dissipation. In the automotive sector, the three-dimensional patterns on interior plastic trim components are also achieved through milling, enhancing visual texture and quality.

CNC Plastic Turning

CNC plastic turning primarily processes cylindrical, conical, and cubic parts with rotational symmetry. This process involves the workpiece rotating at high speed around a spindle while a fixed cutting tool moves along the workpiece’s axis or radially to remove excess plastic. Offering high efficiency, stable precision, and rapid processing speeds, it is ideal for batch production of shafts, sleeves, and discs. For instance, in the home appliance sector, plastic bearing rings undergo turning to ensure coaxial alignment between the inner bore and outer diameter, guaranteeing smooth bearing operation. In the medical field, disposable plastic syringe plungers achieve precise diameter control through turning, preventing jamming during use.

CNC Plastic Drilling

CNC plastic drilling is a specialized process using drill bits to create circular holes in plastic workpieces, enabling precise hole positioning, diameter control, and depth control. Compared to manual drilling, CNC drilling eliminates issues like hole misalignment and inconsistent diameters while supporting simultaneous multi-station drilling to boost efficiency. For instance, plastic circuit board brackets in electronic devices require multiple mounting holes at precise locations. CNC drilling ensures these holes perfectly align with the circuit board’s screw holes. In the furniture industry, plastic connectors benefit from through-holes created by drilling, guaranteeing assembly stability.

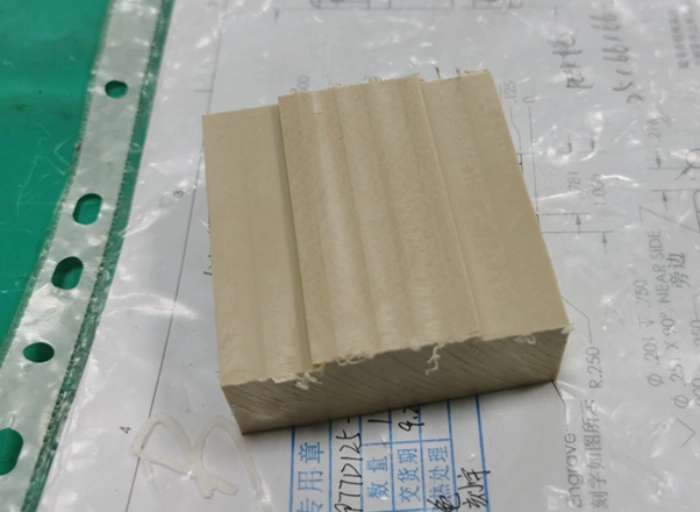

CNC Plastic Routing

CNC plastic routing primarily processes intricate patterns, text, shallow grooves, and other structures on the surface or interior of plastic workpieces. It typically employs small-diameter cutters and leverages high-precision CNC systems to achieve micron-level engraving accuracy. This process is widely used in the production of decorative and identification components. For instance, in consumer electronics, plastic phone cases can be engraved with logos or personalized designs. Instrument panels feature engraved scale lines and button recesses, enhancing operational convenience and visual recognition.

Material Types for CNC Plastic Machining

ABS (Acrylonitrile Butadiene Styrene Copolymer)

ABS plastic combines toughness, rigidity, and impact resistance. Its surface is easily processed (e.g., painting, electroplating) and it offers moderate cost, making it one of the most commonly used materials in CNC machining. Parts processed from ABS exhibit excellent dimensional stability and are resistant to deformation. It is suitable for electronic device enclosures (e.g., computer chassis, printer housings), automotive interior components (e.g., dashboard panels), toy parts, and more.

PC (Polycarbonate)

PC plastic offers high light transmission (approximately 90%, comparable to glass), exceptional impact resistance (250 times stronger than ordinary glass), and good heat resistance (operating temperature range: -40°C to 120°C). During CNC machining, cutting temperatures must be carefully controlled to prevent stress cracking. Primary applications include optical components (e.g., LED lamp covers, eyeglass frames), medical device housings (requiring transparency and sterilization resistance), and automotive lamp covers.

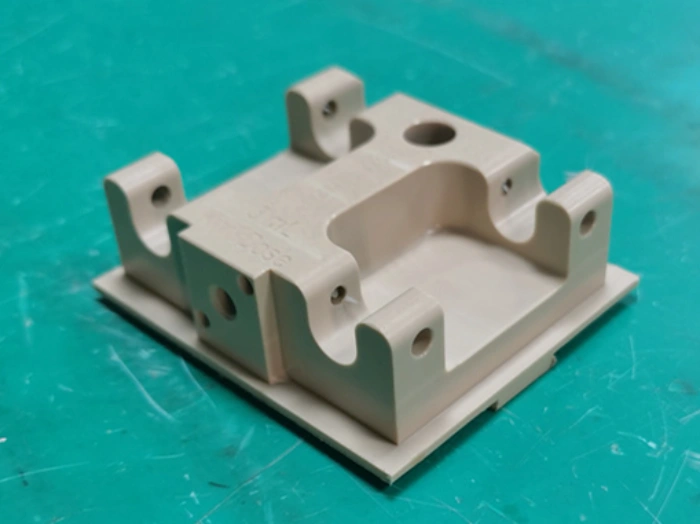

PEEK (Polyetheretherketone)

PEEK is a high-performance engineering plastic offering exceptional heat resistance (long-term service up to 250°C), chemical corrosion resistance (withstands most acid/alkali solutions), and mechanical strength, while meeting medical industry biocompatibility standards. Due to its high hardness and machining complexity, it is typically precision-machined using 5-axis CNC machines. Today I observed a PEEK machining project on a 5-axis machining center. Five planar surfaces underwent drilling and milling operations. The specific application remains confidential to the client. Below are actual photos of the part. Designed for repeated use in high-temperature sterilization environments, it requires precise clamping force control. PEEK’s properties and the precision of 5-axis machining perfectly meet these demands. PEEK is also used in aerospace for high-temperature structural components (e.g., plastic assemblies around engines).

POM (Polyoxymethylene, also known as Acetal)

POM plastic offers high hardness, excellent wear resistance, low friction coefficient, and superior dimensional stability. Machined parts feature smooth surfaces, often eliminating the need for post-polishing. It is ideal for components requiring frequent motion and low wear, such as gears (e.g., toy gears, home appliance transmission gears), bearings, and fasteners (e.g., screws, nuts). POM is widely used in the automotive and home appliance industries.

Nylon (PA)

Nylon plastic offers high toughness, fatigue resistance, and moderate oil resistance and wear resistance. However, its moisture absorption requires attention during processing—pre-drying is essential to prevent post-processing cracking. Depending on the grade (e.g., PA6, PA66, PA610), it can be used for automotive fuel line fittings, electronic device cable protectors, and wear-resistant shims in industrial machinery.

PE (Polyethylene, including HDPE/LDPE)

PE plastics are categorized into high-density polyethylene (HDPE) and low-density polyethylene (LDPE): HDPE offers higher hardness and chemical resistance, suitable for chemical storage tanks and food packaging containers; LDPE provides superior toughness and flexibility, commonly used in plastic films, hoses, and toy components. When CNC machining PE, note its tendency to deform. Secure workpieces properly and control cutting speeds.

PMMA (Polymethyl Methacrylate, commonly known as Acrylic)

PMMA boasts exceptional light transmission (up to 92%, surpassing PC), excellent surface gloss, and ease of engraving and polishing, making it the preferred material for “transparent plastic processing.” However, PMMA is relatively brittle, requiring avoidance of severe impacts during machining to prevent material fracture. Primary applications include advertising light boxes, display stands, optical lenses, and transparent panels for instruments and meters.

PP (Polypropylene)

PP plastic has low density (approximately 0.9 g/cm³, one of the lightest common plastics), excellent chemical resistance (tolerates most organic solvents), good heat resistance (can withstand short-term use around 100°C), and superior flexural fatigue resistance (commonly known as “flex-resistant plastic”). When CNC machining PP, note its tendency to stick to cutting tools; specialized anti-stick tools are required. Suitable for food contact parts (e.g., plastic tableware, water cups), chemical pipelines, and automotive bumper liners.

PBT (Polybutylene Terephthalate)

PBT plastic offers excellent high-temperature resistance (long-term service temperature around 120°C to 150°C), weather resistance, and electrical insulation properties, coupled with high mechanical strength. It is often reinforced with glass fiber (e.g., PBT+30% GF) to enhance toughness. Suitable for components requiring high-temperature resistance and insulation in the electronics industry, such as connectors, relay housings, and automotive sensor casings.

PEI (Polyetherimide)

PEI is a high-performance, high-temperature-resistant plastic with a long-term service temperature up to 170°C. It offers excellent mechanical strength, electrical insulation, and radiation resistance while meeting medical biocompatibility standards. CNC machining is challenging and requires high-hardness cutting tools. Primarily used in aerospace electronic component housings, radiation sterilization components for medical devices, and high-temperature resistant parts for premium home appliances.

PET (Polyethylene Terephthalate)

PET plastic offers high mechanical strength, wear resistance, excellent chemical resistance, and strong barrier properties (particularly against oxygen and water vapor). Common applications include food packaging (e.g., plastic beverage bottles—though typically blow-molded, customized caps and stoppers can be CNC-machined), membrane switches in electronics, and interior trim components in the automotive industry.

PS (Polystyrene)

PS plastic offers good transparency (standard PS has approximately 80% light transmittance), low processing difficulty, and low cost. However, it is relatively brittle and has poor impact resistance. It is suitable for applications with low mechanical strength requirements, such as disposable tableware, toy casings, internal support components for electronic devices, and advertising display models.

PVC (Polyvinyl Chloride)

PVC plastics are categorized into rigid PVC and flexible PVC: Rigid PVC offers high hardness and excellent chemical resistance, making it suitable for plastic pipes, door/window profiles, and industrial equipment housings. Flexible PVC (containing plasticizers) provides superior flexibility and is commonly used in hoses, electrical cable insulation, and waterproof membranes. When CNC machining rigid PVC, note that harmful gases may be released during processing, necessitating ventilation equipment.

Teflon (Polytetrafluoroethylene, PTFE)

Teflon plastic boasts an extremely low friction coefficient (earning it the title “King of Plastics”), outstanding chemical resistance (withstanding strong corrosive solutions like aqua regia), and high-temperature tolerance (operating range approximately -200°C to 260°C). However, it presents significant processing challenges, carries high costs, and exhibits low mechanical strength. Suitable for manufacturing sealing components in the chemical industry (e.g., valve seals), corrosion-resistant parts in the medical field, and custom seals via CNC machining.

Below we summarize the characteristics and applications of CNC plastics machining in a table

| Material | Key Properties | Typical Applications |

|---|---|---|

| ABS | Tough, dimensionally stable, easy to surface finish (painting, electroplating), moderate cost | Electronic housings (computer chassis, printers), automotive interior parts, toy components |

| PC | High transparency (~90%), excellent impact resistance, good heat resistance (-40~120°C) | Optical components (lamp covers, eyeglass frames), medical housings, automotive lamp covers |

| PEEK | High strength, long-term heat resistance up to 250°C, chemical resistance, biocompatible | Aerospace structural parts, medical implants, high-temperature components |

| POM | High hardness, wear resistance, low friction, excellent dimensional stability, smooth surface finish | Gears, bearings, sliders, screws, nuts |

| PA | High toughness, fatigue resistance, wear resistance, but high moisture absorption (requires pre-drying) | Automotive fuel line fittings, cable protectors, industrial wear pads |

| PE | HDPE: high hardness, chemical resistance; LDPE: high toughness, flexibility | Chemical tanks, food containers, plastic films, toy parts |

| PMMA | Excellent transparency (92%), glossy surface, easy to polish but brittle | Light boxes, display stands, optical lenses, transparent panels |

| PP | Low density (~0.9 g/cm³), chemical resistance, good heat resistance (~100°C short-term), flexural fatigue resistance | Food-contact parts, chemical pipelines, automotive bumper liners |

| PBT | Heat resistance (120~150°C), weather resistance, high electrical insulation, strong mechanical properties | Electronic connectors, relay housings, automotive sensor casings |

| PEI | High strength, heat resistance (up to 170°C), electrical insulation, radiation resistance, biocompatibility | Aerospace electronic housings, sterilizable medical components, high-end appliance parts |

| PET | High strength, wear resistance, chemical resistance, excellent barrier properties | Food packaging (caps, stoppers), electronic membrane switches, automotive trim |

| PS | ~80% transparency, low cost, easy to process but brittle and low impact resistance | Disposable tableware, toy casings, electronic device supports |

| PVC | Rigid PVC: high hardness, chemical resistance; Flexible PVC: high flexibility | Pipes, window/door profiles, cable insulation, waterproof membranes |

| PTFE | Extremely low friction, outstanding chemical resistance, wide temperature range (-200~260°C), but low strength and high cost | Chemical seals, corrosion-resistant medical parts, valve sealing components |

How to Select the Most Suitable Plastic for Processing ?

When choosing plastic materials for precision machining, it is recommended to comprehensively consider the part’s application scenario, performance requirements, processing costs, and process compatibility. Follow these specific steps:

Define Core Performance Requirements

First, determine the part’s key performance metrics:

If transparency is required (e.g., optical components), prioritize PMMA (highest light transmittance) or PC (better impact resistance); For high-temperature resistance (e.g., aerospace, medical sterilization), choose PEEK (250°C long-term use), PEI (170°C), or Teflon (260°C); For wear resistance (e.g., gears, bearings), select POM (low friction coefficient), Nylon (fatigue resistance), or Teflon (low friction); For food contact applications (e.g., tableware), select PP (chemical resistance, non-toxic) or PET (safe and stable).

Consider the operating environment

Evaluate environmental factors:

Chemical environments (acid/alkali exposure): Teflon (high corrosion resistance), HDPE (chemical resistance), or PP (resistance to most solvents); For humid environments (e.g., bathrooms, underwater), choose POM (non-absorbent) or PE (water-resistant), avoiding Nylon (water-absorbent). For low-temperature environments (e.g., cold chain equipment), select PE (excellent low-temperature resistance) or PP (usable down to -40°C), avoiding PMMA (becomes brittle at low temperatures).

Balance processing costs and efficiency

High-performance materials (e.g., PEEK, PEI) offer superior properties but come with high costs and complex machining requirements (5-axis machines, specialized tools), making them suitable for high-end precision applications (medical, aerospace). For general consumer parts (e.g., toys, standard enclosures), opt for low-cost, easy-to-machine ABS, PS, or PP to reduce upfront investment and CNC processing time.

Adapting to CNC Machining Processes

Certain materials have specific machining requirements that must be verified against machine tool capabilities: PEEK requires 5-axis high-precision machines; if only 3-axis machines are available, material substitution is necessary. Nylon requires drying treatment; if production facilities lack drying equipment, advance planning is essential. PMMA exhibits high brittleness; for parts with complex deep cavities, assess fracture risk during machining and switch to impact-resistant PC if warranted.

Reference Similar Cases and Industry Standards

For established industry applications (e.g., automotive connectors, electronic enclosures), consult common industry materials: automotive interiors typically use ABS (cost-performance balance), electronic connectors use PBT (high-temperature resistance + insulation), and medical surgical instruments use PEEK (biocompatibility + sterilization resistance). Simultaneously, comply with industry standards (e.g., medical applications require ISO 10993 biocompatibility compliance; food contact requires FDA certification).

6 Common Surface Finishes for CNC Plastic Machining

Sand Blasting

Sand (Bead) blasting uses high-pressure airflow to propel fine abrasives (e.g., glass beads, plastic beads) onto plastic part surfaces, creating a uniform matte or frosted texture. This non-contact process prevents scratches and conceals machining marks (e.g., CNC tooling lines), enhancing part appearance consistency. Suitable for ABS, PC, PMMA, and similar materials, it is commonly used on electronic device housings (e.g., laptop bases) and automotive interior components (e.g., air vent panels) for aesthetic appeal and fingerprint resistance.

Painting

Painting involves uniformly coating parts with specialized plastic paints (e.g., acrylic, polyurethane) using spray equipment. This achieves diverse color effects (e.g., matte black, metallic finishes) and gloss levels (high-gloss, matte), while enhancing scratch resistance and weatherability. Prior to processing, the part surface must be cleaned (removing grease and dust). Certain materials (e.g.,PP) require surface activation treatment to ensure paint adhesion. Suitable for all types of plastics, this process is widely used in consumer electronics enclosures (e.g., phone cases), toys, and home appliance exterior components.

Brushing/Polishing

Brushing: Unidirectional friction applied to the part surface using grinding wheels or brushing cloths creates uniform linear patterns, enhancing a metallic texture (though applied to plastic, it simulates a brushed metal effect). Suitable for moderately hard materials like ABS and PC, commonly seen in automotive interior trim and electronic device bezels (e.g., tablet frames).

Polishing: Refining the part surface with tools like grinding wheels and polishing compounds to achieve a mirror-like finish (particularly suitable for transparent materials like PMMA and PC). For instance, acrylic display stands gain enhanced light transmission and visual quality through polishing; plastic lenses require polishing to ensure optical performance.

Powder Coating

Powder coating involves applying plastic powder (e.g., epoxy resin powder) to a part’s surface via electrostatic adhesion, followed by high-temperature curing to form a uniform coating. This coating offers substantial thickness (typically 50-150μm), excellent impact resistance, strong chemical corrosion resistance, and environmental friendliness (no solvent emissions). Suitable for high-temperature-resistant plastics like HDPE, PVC, and ABS (curing temperatures usually range from 120-180°C, requiring material tolerance), it is commonly used for industrial machinery housings and outdoor plastic components (e.g., plastic parts for park benches).

Electroplating

Plastic electroplating involves surface activation (e.g., chemical copper or nickel plating) followed by electrolytic deposition of metallic layers (e.g., chrome, nickel, gold). This process achieves metallic luster (e.g., silver, gold) while enhancing conductivity, wear resistance, and oxidation resistance. Suitable for materials like ABS (offering best plating adhesion) and PC, it’s commonly used for decorative parts (e.g., automotive wheel hub plastic caps, cosmetic packaging bottles) and conductive electronic components (e.g., connector contacts). Note that electroplating involves complex processes, higher costs, and potential water pollution risks.

Water Transfer Printing

Water Transfer Printing involves floating a transfer film printed with patterns (e.g., wood grain, carbon fiber texture, camouflage) on water. Water pressure transfers the film onto the part surface, followed by drying and sealing to achieve precise replication of complex designs. This process enables printing on irregular curved surfaces (e.g., plastic handles, automotive interior curved components) with strong pattern adhesion and rich color reproduction. Suitable for most plastics including ABS, PC, and PMMA, it is widely used in toys, home appliance exterior parts, and automotive interiors (e.g., plastic door panels simulating wood grain).

CNC Plastic Machine Usage Tips

Equipment Debugging and Parameter Settings

Before machining, adjust spindle speed and feed rate based on material properties:

For high-hardness materials like PEEK and POM, increase spindle speed (3000-5000 rpm) and reduce feed rate (50-100 mm/min) to prevent tool wear. For machining tough materials like Nylon and PE, appropriately reduce spindle speed (1500-3000 rpm) and increase feed rate (100-200 mm/min) to prevent material adhesion to the tool.

Check tool accuracy and wear: Calibrate tip radius compensation for new tools. Replace tools promptly if chipping or wear occurs (e.g., burrs on machined surfaces) to maintain machining precision.

Adapt workpiece clamping to material properties:

For brittle PMMA, use soft fixtures (e.g., rubber pads) to prevent breakage from excessive clamping force. PE and PP are prone to deformation, requiring multi-point clamping to ensure workpiece stability during machining.

Machining Process Monitoring and Quality Control

Conduct a “test cut” during initial machining: After processing 1-2 sample parts, verify dimensional tolerances using calipers and micrometers. Proceed with batch production only after confirming compliance to prevent batch scrap due to parameter errors.

Monitor cutting conditions in real time: Immediately halt operations and inspect if abnormal noises (e.g., tool-workpiece collisions) or smoke (e.g., excessive cutting temperatures) occur during machining. Address issues like tool wear or loose workpieces.

Control environmental temperature and humidity: Certain materials (e.g., Nylon, ABS) are humidity-sensitive. Maintain workshop humidity between 40%-60% to prevent moisture absorption causing post-machining part deformation. For high-precision parts, maintain stable workshop temperatures (e.g., 20±2°C) to prevent machine errors caused by thermal fluctuations.

Equipment Maintenance and Care

After daily operations, clean the machine bed and guideways: Use compressed air to remove plastic debris, then wipe guideways with a cloth and apply lubricant to prevent scratches or rust.

Regularly inspect cutting fluid: Cutting fluid cools tools and reduces friction. Weekly checks are required for fluid level and concentration. Replenish promptly when low, and replace completely when degraded (especially when machining materials like PVC or PE that generate significant debris, requiring frequent fluid changes).

Protect equipment during extended downtime: If equipment remains unused for over one week, clean tools and spindles, apply rust-preventative oil, disconnect power, and cover with a dust cover to prevent dust ingress that could compromise precision.

Application Fields of CNC Plastic Parts

Aerospace Industry

The aerospace sector demands parts with extreme lightweight properties, high-temperature resistance, and radiation tolerance. CNC plastic machining meets these stringent requirements. For instance:

Engine-peripheral plastic brackets machined from PEEK operate stably at high temperatures (250°C) while weighing only one-third of metal counterparts, reducing overall aircraft weight. Satellite electronic component housings machined from PEI exhibit radiation resistance, shielding internal circuits from intense space radiation. Additionally, plastic trim components for aircraft interiors (e.g., seat armrests, instrument panel covers) achieve compliance with aviation safety standards (such as flame retardancy) while enhancing passenger experience through CNC milling and surface painting.

For Electronic Industry

Electronic components typically feature small, high-precision structures requiring insulation and temperature resistance. CNC plastic machining enables efficient, accurate production. For instance:

Router housings machined from ABS feature CNC-milled cooling vents and interface recesses for precise alignment with internal circuit boards; Connectors machined from PBT + glass fiber offer high-temperature resistance (150°C) and insulation, enabling stable signal transmission within electronic devices; LED display transparent covers machined from PMMA achieve 92% light transmittance after polishing, ensuring optimal display performance; Additionally, internal support components and spacers (e.g., machined from POM) maintain dimensional tolerances within ±0.01mm, ensuring compact assembly without loosening.

Medical Applications

The medical field imposes stringent requirements on parts’ biocompatibility, sterilization resistance, and precision. CNC plastic machining (especially 5-axis machining) is one of the core processes. For example: – Minimally invasive surgical instrument gripper heads machined from PEEK comply with ISO 10993 biocompatibility standards, withstand high-temperature/high-pressure sterilization (134°C), and achieve precision within ±0.005mm, ensuring accurate tissue grasping during surgery; Transparent panels for medical monitors machined from PC resist alcohol disinfection while offering high light transmittance, facilitating data monitoring by medical staff. Syringe seals machined from Teflon feature low friction coefficients and chemical corrosion resistance, preventing medication contamination. Additionally, prosthetic components (e.g., joint connectors machined from Nylon) achieve personalized fit through CNC machining, enhancing patient comfort.

Automotive Industry

Automotive components require weather resistance, vibration resistance, and lightweight properties. CNC plastic machining meets both mass production and customization demands. For instance, ABS-machined dashboard panels undergo surface brushing for enhanced texture and withstand temperatures from -40°C to 80°C, adapting to diverse climates. POM-machined door lock gears deliver superior wear resistance, ensuring long-term durability. PP-machined automotive bumper liners offer high toughness and light weight to absorb collision energy. Additionally, battery housing components for new energy vehicles (e.g., PC + glass fiber) provide insulation and high-temperature resistance to safeguard battery safety. CNC-turned air conditioning vent adjustment knobs (e.g., Nylon) achieve precise diameter control for smooth operation.

New Energy Sector

Components for new energy applications (e.g., photovoltaics, wind power, energy storage) require weather resistance, insulation, and chemical resistance. CNC plastic machining delivers stable, reliable solutions. For instance:

Photovoltaic inverter housings made from HDPE withstand UV radiation and rain erosion, safeguarding internal circuits during prolonged outdoor operation; PVC-machined insulation layers for wind turbine cables offer superior insulation and low-temperature resistance (-30°C operational capability), adapting to harsh wind power environments; PP-machined energy storage battery trays are lightweight and chemically resistant, preventing electrolyte leakage. Additionally, plastic enclosures for new energy vehicle charging stations (e.g., manufactured from ABS + flame retardant) feature flame resistance and impact resistance, ensuring charging safety.

Contact Weldo

For CNC plastic processing needs (e.g., custom parts, batch production) or to explore industry application cases (e.g., medical PEEK part manufacturing, aerospace plastic structural components), contact the Weldo team via:

Official Email: Send your request to cg@weldomachining.com. Our staff will respond within 12 hours with tailored solutions and quotations.

On-site Visit: Visit Weldo’s production base (Address: No. 109 Baxin Road, Wanjiang District, Dongguan City, Guangdong Province) to inspect our CNC machining center.

Mention “CNC Plastic Machining Inquiry” when contacting us to receive a complimentary copy of the Weldo CNC Plastic Machining Case Study Handbook (featuring 100+ real-world examples across aerospace, medical, electronics, and other industries, detailing material selection, machining processes, and cost analysis).

CNC plastic machining guideline FAQ

1. What tolerance accuracy can CNC plastic machining achieve?

Tolerance accuracy varies by material and machine configuration:

– Standard 3-axis machines machining ABS, PC, etc., can achieve tolerances of ±0.01mm.

– 5-axis high-precision machines machining PEEK, PMMA, etc., can achieve tolerances as low as ±0.005mm.

– For higher precision requirements (e.g., ±0.002mm), customized cutting tools and temperature-controlled machining environments are necessary.

Specific requirements can be discussed with Weldo’s technical team based on part specifications.

2. For small-batch production (e.g., 50 pieces), should I choose CNC plastic machining or injection molding?

Prioritize CNC plastic machining. Injection molding requires tooling (typically costing tens of thousands of RMB with a 2-4 week lead time), making tooling costs disproportionately high for small batches.

CNC machining eliminates tooling requirements, producing 50 parts in just 3-5 days at 1/3 to 1/2 the cost of injection molding. It also allows for immediate design adjustments (e.g., part dimension changes), making it ideal for R&D prototypes and customized small-batch needs.

3. Why do plastic parts deform after machining? How to resolve it?

Common causes and solutions:

① Material moisture absorption (e.g., Nylon, ABS): Place material in a drying oven (80-100°C, 4-6 hours) before machining to remove moisture.

② Excessive cutting temperature (e.g., machining PC, PEEK): Reduce spindle speed, increase coolant flow to cool the tool and workpiece.

③ Improper workpiece clamping (e.g., PE, PP): Use multi-point clamping (3+ fixed points) or vacuum suction cups to prevent displacement and deformation during machining.

4. Do surface treatments (e.g., electroplating, water transfer printing) affect part dimensional tolerances?

Minor effects occur, requiring advance allowance. For example:

– Electroplated layers typically measure 5-20μm thick; reduce part dimensions by 5-20μm during machining to ensure final size compliance post-plating.

– Water transfer printing coatings are approximately 10-15μm thick.

For parts with stringent tolerances (e.g., ±0.01mm), dimensions must be adjusted during machining or a surface treatment with minimal dimensional impact should be selected (e.g., bead blasting, which has negligible dimensional effect).

Specific allowances can be determined in consultation with Weldo’s surface treatment team based on the process type.