Wire edm machining

Overview

Our professional Wire EDM Machining service can meet the machining requirements of high-precision, complex-shaped parts,no cutting stress.

Tolerance: ±0.00004 inch

Material Options: Tool steels (D2, A2, H13),Stainless steel (304, 316, 17-4PH),Carbide,Titanium & titanium alloys,Aluminum alloys,Copper, brass, tungsten, molybdenum.

Applications & Part Types: Injection mold inserts and cavities,Progressive stamping dies,Precision gears & micro-gears,Aerospace turbine components,Medical device metal components,Custom metal brackets, shims, anthin-wall structures etc.

Price range: 20~500 USD/PCs

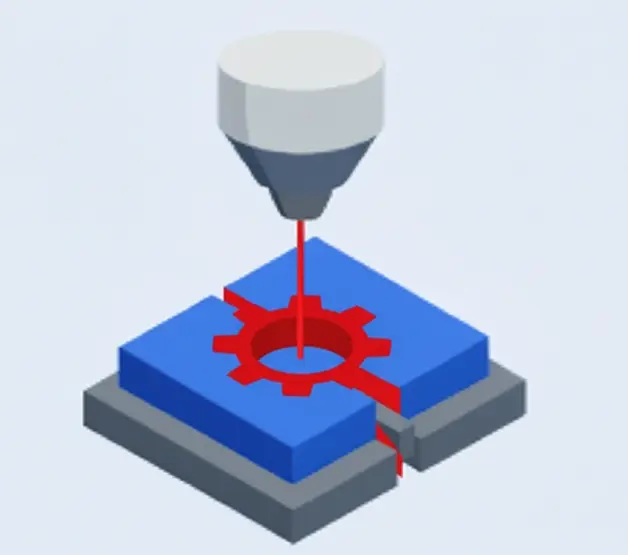

What is wire edm machining ?

Wire EDM (Electrical Discharge Machining) is a precision machining process that uses fine metal wire (usually copper or molybdenum) to create electrical sparks between the wire and the workpiece. The sparks melt or vaporize the material, enabling precise cutting. Wire EDM is widely used for machining complex shapes, high-precision parts, and hard materials in industries such as mold making, aerospace, and automotive. Its key advantages include no tool wear and high accuracy.

EDM is divided into fast wire, slow wire and medium wire EDM

Material for wire EDM machining

Wire EDM machining can process conductive materials with high hardness, complex shapes or that are difficult to process with traditional machining.

Material :

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Copper

Possesses electrical conductivity, tensile ductility, and antimicrobial properties, primarily used for processing into crafts, decorative items, and medical equipment.

Color :Orange,yellow.

Types : copper H59/H62/Hpb59-1/C36000/HAI77-2/HSN62-1/HPb/HMn/HAl/HSn/HNi.

Surface finish : Passivation, Electroplating, Chemical Plating, Shot Peening, Sandblasting, Chemical Film Treatment, Polishing, Bright Cleaning.

Delivery time : 1-5 days.

Bronze

Bronze is an alloy of copper and tin (possibly including lead, zinc, and phosphorus),low melting point (800-900°C) and excellent fluidity, along with corrosion resistance. Low-tin bronze exhibits a golden yellow hue, while high-tin bronze appears grayish-white or silver-gray. It is primarily used in mechanical manufacturing for sculptures, bearings, gears, valves, as well as in marine engineering components such as propellers, as well as marine engineering components like hull fittings and water pumps.

Color : gold/brown.

Types : Tin bronze, aluminum bronze, beryllium bronze, silicon bronze, manganese bronze.

Surface finish : Sandblasting, polishing, knurling, grinding, passivation, chemical film coating, impregnation coloring, brush/spray coloring, electroplating, anodizing, powder coating, brushing.

Delivery time : 1-5 days.

Steel

Iron alloyed with carbon (typically 0.1%-1.7%) and other alloying elements (such as chromium, nickel, manganese, etc.). By adjusting composition and heat treatment processes, diverse properties can be achieved, including high strength, high toughness, wear resistance, and corrosion resistance. It is suitable for producing components such as bolts, shafts, gears, drill bits, milling cutters, and turning tools, and is also frequently used in manufacturing engine valves and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

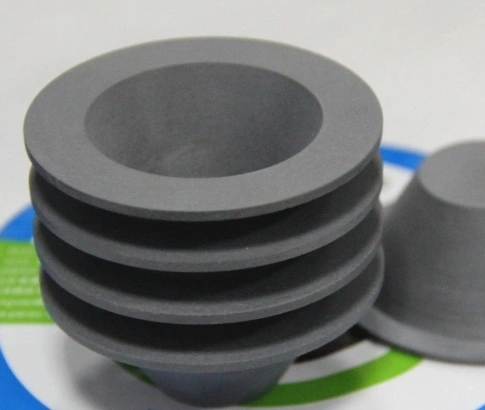

Graphite

Graphite conductivity is used for precision molding to avoid dust pollution caused by machining. It is mainly used for electrode manufacturing and EDM molds.

Color : Black.

Surface finish : Mechanical cutting, pickling, electrolytic treatment, coating, polishing, EDM surface strengthening.

Delivery time : 3-5 days

Conductive ceramic part

Conductive ceramics are used in aerospace and other fields due to their high hardness, brittleness, and excellent chemical stability, but they are difficult to process. Using pulsed discharge to generate high temperatures (approximately 10,000°C) to partially melt the ceramic allows for contactless processing, avoiding stress concentration and cracking caused by mechanical processing.

Type : Oxide/non-oxide conductive ceramics, composite conductive ceramics

Color : white, gold, pink black, etc.

Delivery time : 3-5 days

Surface finish for wire EDM machining

The parts processed by Wire EDM machining usually have certain melting marks and slight deformation on the surface, so they need to be post-processed to improve their performance and appearance. Common surface treatment processes include:

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance. suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

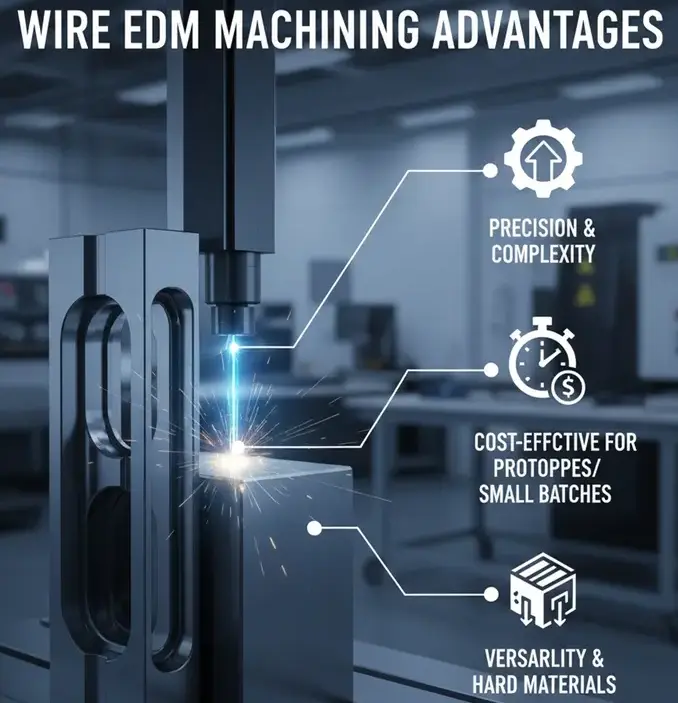

Wire EDM machining advantage

High Precision: Wire EDM machining achieves extremely high machining accuracy, with tolerances reaching ±0.001mm or even finer, making it suitable for manufacturing complex parts with demanding requirements.

No Physical Contact: During machining, the wire does not come into direct contact with the workpiece surface, preventing tool wear and thermal deformation. This makes it suitable for machining materials with varying hardness and softness.

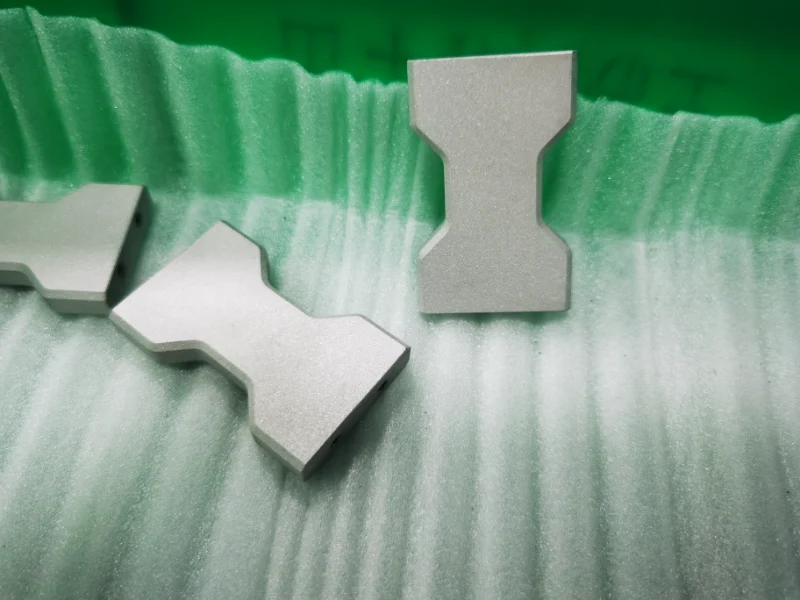

Machining Complex Shapes: Wire EDM is particularly well-suited for machining parts with complex geometries or fine details, such as internal holes and tiny cuts.

Suitable for High-Hardness Materials: Wire EDM can process materials with hardnesses of up to 60HRC or higher, making it suitable for machining materials difficult to machine with traditional cutting methods, such as carbide, stainless steel, and titanium alloys.

No Mechanical Stress: Since there is no mechanical contact during machining, stress concentration on the material is reduced, helping to maintain part stability and dimensional accuracy.

High Surface Quality: The machined surface is typically smooth with low surface roughness, requiring less post-processing.

Long-Term Stable Operation: Wire EDM offers high continuous machining capabilities, making it suitable for high-volume production and long-term stable operation.

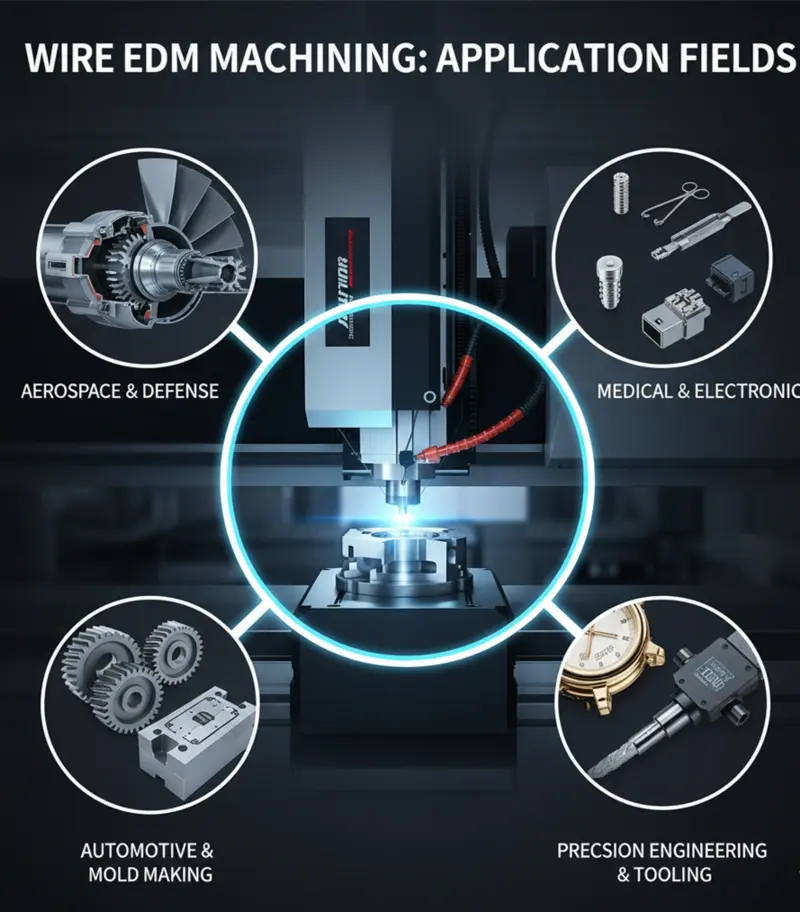

Application of wire EDM machining parts

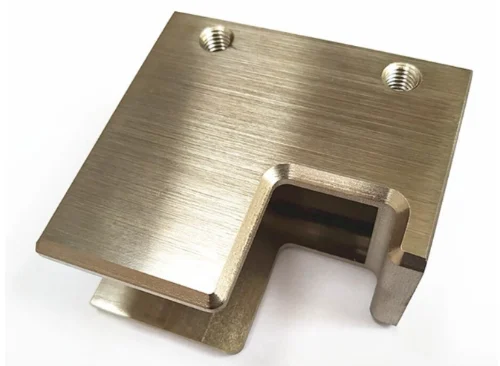

Mold Manufacturing: Wire EDM can be used to produce precision mold components, such as mold cavities, cavities, and complex cooling channels. Wire EDM particularly demonstrates its advantages in the production of high-precision plastic molds and stamping dies.

Aerospace: Aircraft components typically require high precision and complex shapes. Wire EDM can be used to process high-precision parts such as aircraft engine components, gas turbine blades, and gears.

Automotive: Wire EDM has important applications in the manufacture of automotive parts, precision tools, engine components, and precision parts. Wire EDM is an ideal machining method for high-precision automotive accessories such as cooling holes and fuel nozzles.

Medical Devices: Many medical devices and instrument components (such as surgical tools and dental equipment) require high precision and surface finish, and wire EDM is widely used in this field.

Precision Machinery: Wire EDM can be used to manufacture high-precision mechanical components such as gears, bearings, cutting tools, and transmission systems, especially in applications requiring complex geometries and details.

Energy Industry: For example, the manufacturing of components for nuclear power plants and wind turbines. Wire EDM can process high-strength and corrosion-resistant materials, ensuring the stability of these components in high-temperature and high-pressure environments.

Metalworking: Wire EDM is also used in jewelry and artwork, enabling the creation of intricate metal engravings and decorative patterns.

FAQ of wire EDM machining

- Metals: Hard alloy steel, titanium alloy, stainless steel, copper, aluminum, etc.

- Special materials: High-temperature alloys, die steel, EDM-specific materials.

Limitation: Non-conductive materials (e.g., ceramics, plastics) cannot be processed.

Industry applications: Aerospace (turbine blades, discs), medical (implants, surgical instruments), mold making (complex cavities), electronics (micro-components).

Advantages:

- Can cut narrow slots (0.05mm wide) and sharp internal corners (R0.1mm or less);

- High repeat positioning accuracy for mass production;

- Often requires no subsequent polishing.

Case: In aerospace, turbine blade cooling holes must be machined within ±0.003mm tolerance, making Wire EDM the only viable solution.

- Single-piece speed: Slower than milling (~50-200mm²/min), but ideal for complex shapes;

- Mass production advantage: Enables 24/7 unattended operation with automatic wire threading (AWT) and CNC programming;

- Material adaptability: More efficient than milling for hard materials (e.g., HRC60+).

Comparison with milling:

- Advantages: No cutting force (preventing workpiece deformation); can process ultra-hard materials;

- Disadvantages: Slower than milling; may form oxide layers requiring post-cleaning.

Treatment methods:

- Mechanical removal: Sandpaper grinding, sandblasting;

- Chemical cleaning: Acid or alkaline washing;

- Electrochemical polishing: Improves surface finish.

Industry practice: For medical implants, oxide layers must be completely removed to ensure biocompatibility.

- Electric shock: High-voltage sparks may cause electrocution;

- Mechanical injury: Wire breakage or workpiece ejection;

- Fire: Abnormal conductivity of deionized water or flammable oil-based coolants.

Prevention measures:

- Equipment protection: Install lightning protection and emergency stop buttons;

- Operation norms: Never touch the wire; keep electrical cabinets closed during processing;

- Environment control: Maintain dry work areas and regularly inspect coolants.

- Equipment depreciation: High-end machines cost ~$70,000-$280,000;

- Consumables: Wire (~$70-$280 per roll), deionized water (requires regular replacement);

- Energy consumption: ~5-15kWh per hour of machining;

- Labor costs: Requires skilled programmers/operators.

Optimization suggestions:

- Mass production: Reduce manual intervention with CNC programming;

- Material selection: Prioritize highly conductive materials (e.g., copper) to shorten processing time;

- Process optimization: Use rough+finish two-step machining to balance efficiency and precision.