In the pursuit of both high performance and durability in automotive engines, 5-axis CNC machining technology has emerged as a critical solution for manufacturing automotive engine components. This advancement leverages its distinctive features of multi-axis coordination, high precision, and exceptional flexibility. This article examines Weldo Company’s machining case study of the EA855 engine’s 5-cylinder mid-block. It delves into how CNC technology overcomes constraints posed by complex geometries, difficult-to-machine materials, and stringent tolerances through spatial freedom control, material adaptability optimization, and intelligent compensation, thereby providing robust technical support for automotive powertrain systems.

Case Background: Manufacturing Challenges and Technical Requirements for the EA855 5-Cylinder Middle Block

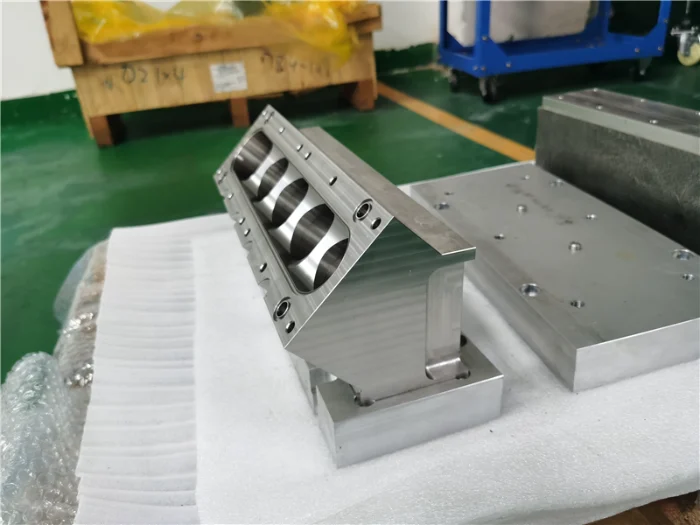

As a premier example of high-performance powertrains, the EA855 engine’s inline 5-cylinder middle block structure offers outstanding advantages in compactness and power output, yet presents immense manufacturing difficulties.

Structural Complexity

The 5-cylinder layout results in densely packed internal water channels, oil passages, and cylinder bores, imposing stringent demands on multi-surface machining and spatial surface precision. Traditional machining methods struggle to meet such intricate structural requirements, whereas multi-axis CNC milling technology effectively addresses this challenge.

Material Specificity

This engine utilizes 316L stainless steel, a material renowned for corrosion resistance and high strength. However, it exhibits pronounced work-hardening tendencies, leading to rapid tool wear and susceptibility to surface defects. Despite this, its hardness makes it easier to machine than cast iron while offering superior toughness, thereby elevating the engine’s horsepower modification potential.

Precision Demands

Tolerance requirements reach ±0.05mm (cylinder bore diameter, flatness) and surface roughness Ra 1.2μm (sealing surfaces, friction pairs), far exceeding conventional machining standards. This imposes near-demanding requirements on machining technology, making 5-axis CNC machining—with its high precision—the ideal solution to meet these standards.

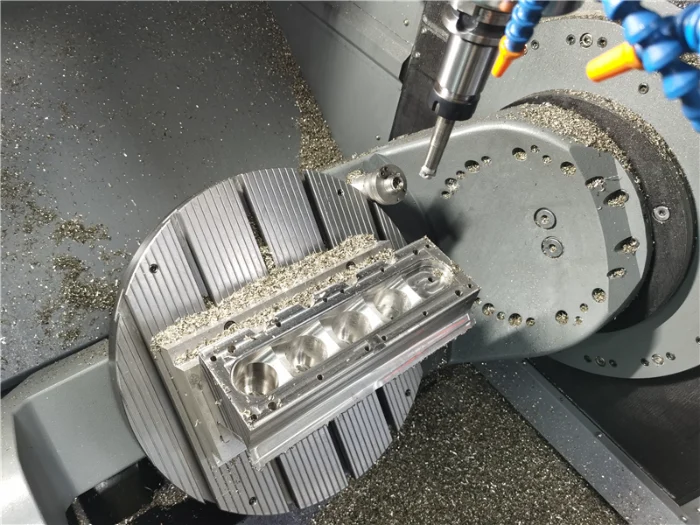

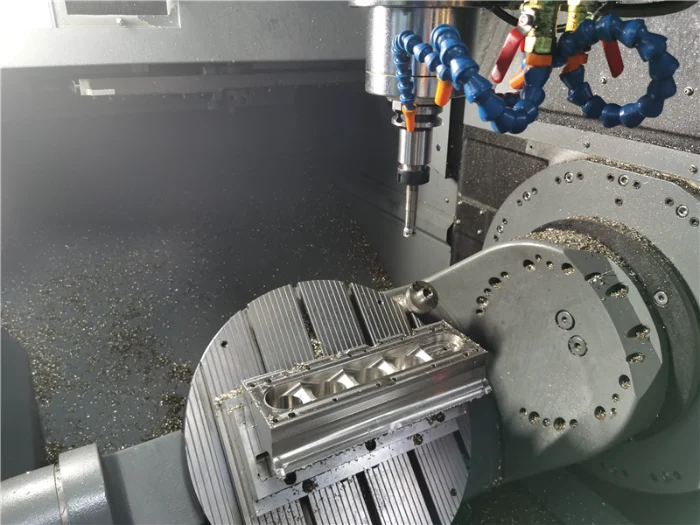

Traditional three-axis machining struggles to balance efficiency and precision due to frequent clamping changes and limited toolpaths. 5-axis CNC, however, controls tool feed along the X, Y, and Z axes through programming. Combined with servo motors and the workpiece base’s rotational axes (A and B axes), it achieves smooth machining of the five combustion chamber surfaces. This ensures the chamber’s surface finish, laying the foundation for normal piston movement and significantly reducing the likelihood of piston ring wear and oil burning caused by aggressive driving.

Analysis of 5-Axis CNC Machining Advantages:

Comprehensive Breakthroughs from Efficiency to Precision

Single-Setup Tooling for Accumulated Error Reduction

The addition of A and C rotary axes in 5-axis CNC enables multi-surface machining with a single workpiece setup, effectively eliminating positioning errors accumulated through multiple setups in traditional three-axis machining. In the machining of the EA855 five-cylinder engine’s middle cylinder, 5-axis technology drastically reduced clamping operations from 6 to just 2. Cylinder bore diameter tolerance was stabilized within ±0.04mm, with flatness error ≤0.03mm—representing a 40% precision improvement over conventional methods. This advantage fully demonstrates CNC milling’s exceptional capability in precision control.

Toolpath Optimization Enhances Machinability of Difficult-to-Machine Materials

For challenging materials like 316L stainless steel, 5-axis CNC machining dynamically adjusts tool angles and periodically lifts the cutter during drilling. This ensures uniform distribution of cutting forces, reducing the risk of overheating during machining. Combined with a high-pressure internal cooling system, cutting temperatures are lowered by 30%, tool life is extended by 30%, and surface roughness is stabilized within Ra 1.2μm. This technological advantage equally applies to machining materials like titanium alloys and high-temperature alloys in components such as turbocharger housings and intake manifolds, demonstrating CNC machining‘s formidable material adaptability.

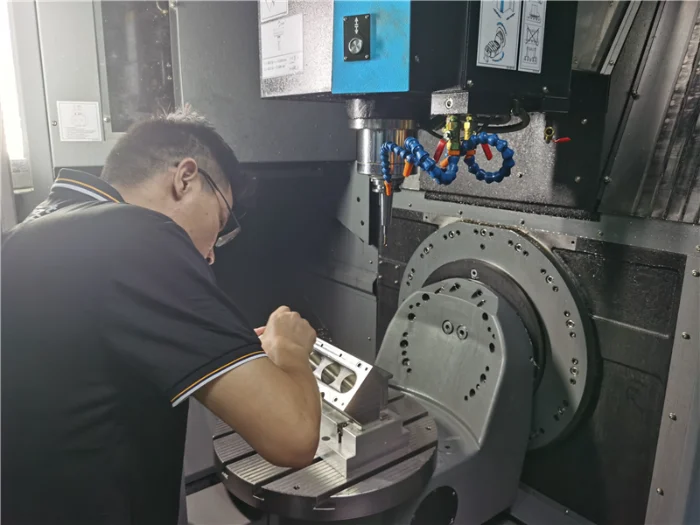

High-Precision Curved Surface Machining

Engine sealing surfaces (e.g., cylinder head gasket contact surfaces) and friction pairs (e.g., piston pin bores) demand extremely high surface roughness (Ra ≤ 1.6 μm). The RTCP function (Rotary Tool Center Positioning) and vibration suppression technology in multi-axis CNC machining ensure the tool remains perpendicular to the machined surface, eliminating surface waviness caused by angular deviation in conventional machining. In EA855 cylinder block seal surface machining, surface roughness achieved Ra 1.0–1.2 μm—a 25% improvement over three-axis machining—significantly reducing leakage risk and ensuring engine sealing performance.

Efficient Deep Cavity and Angled Hole Machining

The A/C-axis linkage in 5-axis CNC machining enables tool feed along any spatial direction, achieving “single-pass” machining of deep cavity structures like engine cylinder waterways and oil passages, as well as inclined injector holes. For instance, single-piece processing time for the waterway in the five-cylinder middle cylinder was reduced from 45 minutes to 18 minutes, boosting production efficiency by 60%. This also eliminates leakage risks caused by tool mark lines, enhancing product reliability.

Multi-Variety Engine CNC Customization Capability

5-axis CNC machining rapidly adjusts toolpaths via CNC programs. Combined with modular fixtures, it enables processing of engine components for different displacements and cylinder counts on a single machine. After integrating 5-axis machining centers into Weldo’s flexible production line, a single line can now process both EA855 five-cylinder and four-cylinder engine blocks. Changeover time has been reduced from 4 hours to 0.5 hours, while equipment utilization has increased to 92%, meeting market demand for customized, multi-variety, small-batch engine products.

Years of multi-axis machining expertise drive material innovation

For lightweight materials like aluminum and magnesium alloys, 5-axis CNC machining employs high-frequency sampling control algorithms and active vibration-damping toolholders to suppress vibration amplitude below 5μm, preventing deformation in thin-walled components. For instance, in aluminum alloy cylinder head machining, wall thickness tolerance improved from ±0.15mm to ±0.08mm. This reduced weight by 15% while maintaining structural integrity, providing robust support for engine lightweight design.

Case Study Outcomes of 5-Axis CNC Milling

Through 5-axis CNC machining technology, the EA855 five-cylinder mid-block project achieved the following performance enhancements:

Efficiency Improvement

Processing cycles were drastically reduced from 12 hours to 4.5 hours, with equipment utilization increasing by 65%, significantly boosting production efficiency.

Precision Compliance

First-pass yield for critical dimensional tolerances and surface roughness reached 99.2%, while scrap rate decreased from 3.5% to 0.8%, ensuring stable product quality.

Cost Optimization

Tool wear rate decreased by 40%, and per-unit processing cost was reduced by 28%, effectively lowering production expenses.

Industry Value of 5-Axis CNC Machining

The advantages of 5-axis CNC machining extend beyond enhancing efficiency in individual processes. It drives a paradigm shift in engine manufacturing—transitioning from “subtractive manufacturing” to “hybrid additive-subtractive manufacturing,” and from “rigid production lines” to “flexible intelligent production lines.” Taking the EA855 five-cylinder mid-block as an example, 5-axis technology delivers a replicable solution for small-batch, customized production of high-performance engines through process integration, material adaptation, and precision control. This empowers the automotive industry to maintain core competitiveness in internal combustion engine technology during its electrification transition.

Conclusion

5-axis CNC machining technology, centered on “spatial freedom control,” redefines the precision boundaries and efficiency limits of engine manufacturing through innovations like single-setup machining, dynamic compensation, and flexible production. This fully demonstrates the technology’s pivotal role in automotive engine manufacturing. For further CNC precision machining needs related to engines, please consult Weldo Company. We can recommend suitable metal materials and machining precision standards tailored to your cost and engine performance requirements, significantly enhancing your product’s cost-effectiveness while meeting your driving needs.