Applications of Aluminum Alloys in 4-Axis CNC Mill

Aluminum alloys have become one of the most widely used non-ferrous metals in 4-axis CNC mill due to their superior specific strength, machinability, and cost-effectiveness. Among these, the three internationally recognized grades—6061-T6, 7075-T6, and 2024-T3—dominate the automotive engineering, aerospace structural components, and high-strength fastener markets respectively. Understanding their performance differences and the logic behind matching their machining characteristics is crucial for precision manufacturing.The following is about 4 axis CNC mill analysis.

Core Alloy Performance Comparison

Below is a comparison of key parameters for these three representative aluminum alloys, with data compiled from international material standards and 4-axis CNC milling practices:

| Alloy Grade | Primary Alloying Elements | Tensile Strength (MPa) | Hardness (HB) | Density (g/cm³) | Machinability | Typical Applications |

|---|---|---|---|---|---|---|

| 6061-T6 | Si (0.6%), Mg (1.0%) | 240-290 | 95 | 2.7 | Excellent | Automobile chassis parts, mechanical supports/brackets, machine frames |

| 7075-T6 | Zn (5.6%), Mg (2.5%) | 570-640 | 150-160 | 2.81 | Medium | Aircraft wings, missile components |

| 2024-T3 | Cu (4.4%), Mg (1.5%) | 430-470 | 120 | 2.78 | Good | Aerospace fittings, high-pressure oil pipes |

Machining Accuracy and Material Selection for 4-Axis CNC Milling

The achievable precision of f-grade (precision grade, ±0.05 mm) and m-grade (medium grade, ±0.1 mm) tolerances under ISO 286 standards directly depends on the cutting stability of the material and the matching of 4-axis CNC milling machine parameters:

6061-T6: Due to its excellent machinability (low cutting forces, continuous chips), it is suitable for mass-production automotive parts requiring m-grade precision, such as transmission housings. Japanese Mazak technical documentation recommends spindle speeds of 1500-3000 rpm and feed rates of 0.1-0.3 mm/r, paired with high-speed steel tools, to meet 4-axis CNC milling requirements .

7075-T6: Its ultra-high strength (572 MPa) causes significant work hardening. Achieving f-grade precision necessitates carbide or PCD tools. The Haas Aerospace Machining Guide recommends 800-1500 rpm spindle speeds and 0.05-0.15 mm/r feed rates, with mist cooling to control thermal deformation. This is typically used for 4-axis CNC milling of aircraft landing gear components.

2024-T3: Its balanced combination of moderate strength and good machinability makes it the preferred choice for aerospace fasteners, reliably achieving tolerances of ±0.08 mm. DMG MORI recommends 2000-4000 rpm spindle speeds and prioritizes fine-pitch milling cutters to minimize surface tearing, which is critical for surface quality control in 4-axis CNC milling .

Key Conclusions: Material strength positively correlates with machining precision requirements, but processing challenges can be mitigated through tool upgrades (e.g., PCD tools for 7075) and parameter optimization. 6061-T6 dominates general engineering markets due to its cost-effectiveness, while 7075-T6 monopolizes high-end aerospace applications in four-axis CNC milling owing to its superior strength.

International Manufacturers’ 4-Axis CNC Mill Parameter References

Mazak 7075-T6 Machining Recommendations: Rough milling with φ20 mm carbide end mills, Vc=300-400 m/min, Ap=5-8 mm; switch to φ10 mm PCD tools for finish milling at Vc=1000-1500 m/min, ensuring Ra≤1.6 μm.

Trumpf 2024 Thin-Wall Machining Solution: Utilizing a high-speed spindle (30,000 rpm) and HSC technology, achieve four-axis CNC milling of 0.5 mm thin-walled components with thermal deformation controlled within 0.02 mm.

These data indicate that four-axis CNC milling of aluminum alloys requires establishing a ternary matching system of “material-tool-machine” to maximize efficiency while meeting ISO tolerance standards.

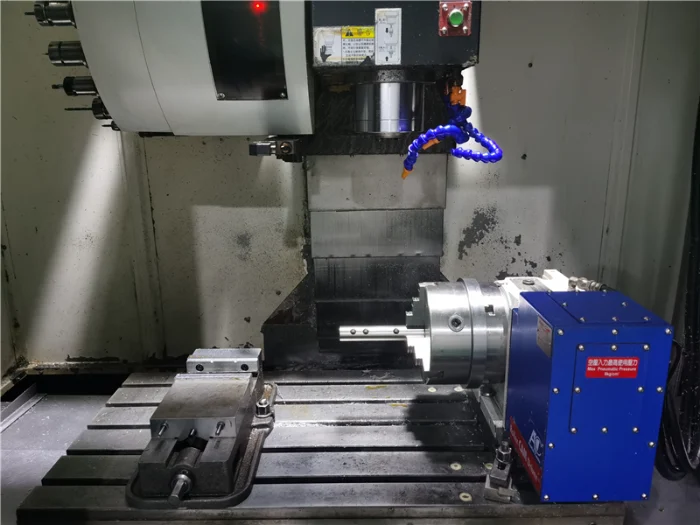

Technical Characteristics of 4-Axis CNC Milling for Aluminum Alloy Parts

4-axis CNC milling technology achieves multi-surface machining of complex aluminum alloy parts in a single setup through coordinated control of the X, Y, Z axes and a rotary axis (typically the A-axis), boosting efficiency by 40% compared to traditional three-axis machining. Its core advantages include reduced clamping frequency (from 3-5 times to just once) and minimized cumulative error (≤±0.01mm), making it particularly suitable for machining large aerospace structural components (e.g., integral blisks) and precision medical parts (e.g., artificial joints). A typical 4-axis CNC milling center features high-precision ball screws and linear guides, achieving positioning accuracy of ±0.006mm and repeatability of ±0.003mm. The rotary axis supports -90° to +90° swivel or 360° continuous rotation to meet multi-angle machining demands.

A comparison of key parameters for mainstream 4-axis CNC milling equipment reveals: The Haas UMC-750 excels in four-axis CNC milling of precision medical components with its ±0.002mm positioning accuracy and modular tool magazine design. DMG MORI’s high-speed four-axis drilling and milling center employs a dual-spindle configuration (9.6kW + 6.0kW) paired with a servo-driven rotary table. This setup enables simultaneous four-axis CNC milling of multiple features—such as beveled holes and lock holes—in aluminum window and door profiles, achieving a 50% efficiency gain over single-spindle models.

Regarding technical standards for 4-axis CNC milling: – ISO 230-1 (Machine Tool Performance Testing Standard) specifies linear axis positioning accuracy tolerance as (0.008 + 0.005L/1000) mm and rotary axis indexing accuracy ≤ ±5″, ensuring foundational equipment precision. The American National Standards Institute (ANSI) B5.54 establishes a comprehensive quality control framework through cutting force testing (deflection <0.01mm at ≤200N) and thermal stability verification (error ≤0.005mm after 4 hours of continuous machining). This system meets ±3μm tolerance requirements for aerospace aluminum alloy components. Real-time compensation via laser interferometer (±0.5μm/m accuracy) and AI-driven cutting parameter optimization (e.g., dynamic feed rate adjustment) achieve micron-level milling stability.

Key optimization points for 4-axis CNC milling

Aluminum alloy 4-axis machining requires specialized tools (e.g., 3-flute PCD milling cutters), cutting speeds of 2000 m/min, feed rates of 30-50 m/min, and micro-atomized cooling systems (pressure 0.5-0.8 MPa) to prevent tool adhesion and oxidation. For thin-walled components (wall thickness < 2 mm), adopt axial clamping with auxiliary support fixtures. Continuously adjust cutting parameters during milling via vibration monitoring (threshold ≤ 0.1g).

Application Case Analysis of 4-Axis CNC Milling Technology

4-axis CNC milling technology, leveraging its capability to process complex surfaces and high precision characteristics, has achieved deep application in critical sectors such as aerospace, automotive manufacturing, and medical equipment. This has formed a three-dimensional technology implementation system centered on “industry demand-material properties-process innovation.” The following analysis combines international manufacturers’ technical documentation with typical finishing case studies:

Aerospace Sector: 4-Axis CNC Milling for Lightweight, High-Strength Structural Components

The aerospace industry’s demand for lightweight aluminum alloy parts with complex geometries has driven breakthroughs in four-axis CNC milling technology. Taking the machining of 7075-T6 aluminum alloy engine blades as an example, Mazak 5-axis Linkage equipment (though a 5-axis case, four-axis technology serves as the foundational support) was employed. By combining A-axis rotation with XYZ-axis Linkage, the blade surface was machined in a single setup. This reduced clamping operations by 30% compared to traditional three-axis processes, significantly lowering cumulative errors. For thin-walled irregular components (with material removal exceeding 80%) processed by an aerospace enterprise, 4-axis milling with core shaft positioning technology (radial runout ≤0.01 mm, concentricity ≤0.02 mm) boosted processing efficiency by 75%, replacing the original five-axis solution. Additionally, the 2024-T4 aluminum alloy airframe structure employs a 4-axis milling layered process. This achieves a 15% weight reduction while maintaining a tensile strength of 470 MPa, meeting the stringent requirements of aircraft like the C919.

Automotive Manufacturing: 4-Axis CNC Milling for Precision Powertrain Components

Forty percent of the automotive industry’s CNC machine tool demand centers on four-axis CNC milling for aluminum alloy powertrain components. The 6061-T6 aluminum alloy cylinder block is processed using a Japanese Fanuc Robodrill machining center, implementing a “rough machining + two-stage finishing” process: Roughing removes 85% of stock at 120 mm²/min efficiency, while finishing achieves Ra 1.6 μm surface roughness via a 10,000 rpm high-speed spindle. For new energy vehicle battery tray machining, 4-axis CNC milling equipment utilizes U-axis oscillation to form complex T-slots in a single operation, controlling tolerances to ±0.05 mm to meet battery module sealing requirements. Automotive component manufacturers employ four-axis mill-turn technology for transmission housing machining, boosting production efficiency by 30% while achieving critical hole system positional accuracy ≤0.02 mm.

Medical Devices: Biocompatible 4-Axis CNC Milling for Implants

Demand for surface quality and geometric precision in aluminum alloy medical implants drives innovation in 4-axis CNC milling. When machining 2024 aluminum alloy orthopedic implants, GF Machining Solutions’ MIKRON HSM 400U achieves a Ra 0.8 μm mirror finish through 4-axis synchronized motion and ultra-hard coated tools (WC-Co material), reducing the risk of postoperative inflammatory reactions. In four-axis CNC milling of dental abutments, a distributed control system drives the A-axis for 360° continuous rotation. Paired with a 0.1 mm diameter ball-nose cutter, it completes complex annular engraving with surface transition errors ≤0.03 mm. For artificial joint stems produced by medical enterprises, 4-axis side-milling processes create porous structures, increasing osseointegration area by 40% compared to traditional methods.

Summary of 4-Axis CNC Milling Technology Features

Aerospace: Primarily utilizes high-strength aluminum alloys like 7075-T6 and 2024-T4, with core metrics being weight reduction rate (15%-20%) and surface profile accuracy (≤0.05 mm).

Automotive Manufacturing: 6061-T6 accounts for over 60% of applications, with breakthroughs focused on complex cavity machining efficiency (120-150 mm²/min).

Medical Field: 2024 aluminum alloy implants must simultaneously meet surface finish (Ra ≤ 0.8 μm) and biocompatibility requirements.

Applications across sectors demonstrate the technical logic of four-axis CNC milling: “reduce setups, boost efficiency, ensure precision.” Key differentiated challenges include material removal rates in aerospace, batch stability in automotive, and surface quality in medical devices. These demands drive four-axis milling equipment toward high-speed (spindle speeds 15,000–40,000 rpm) and intelligent (adaptive feed control) advancements.

Global Market and Industry Trends for 4-Axis CNC Milling

The global market size for 4-axis CNC milling machines reached $64.598 billion in 2025 and is projected to grow at a CAGR of 3.78%, reaching $83.756 billion by 2032. This growth is primarily driven by demand for high-precision aluminum alloy components in the aerospace and automotive industries. The aviation sector’s shift toward lightweight electric aircraft is boosting consumption of 7075-T6 aluminum alloy, while new energy vehicle manufacturers increasingly adopt 4-axis milling technology to process complex powertrain components, creating sustained growth momentum for the market.

Technological Evolution and Innovation Drivers in 4-Axis CNC Milling

The industry is witnessing two transformative trends: AI-driven intelligent optimization and sustainable manufacturing practices. Software solutions like Mastercam 2025 integrate AI-powered tool life prediction algorithms, reducing four-axis milling errors by 18% and extending tool life by 22% through real-time parameter adjustments. On the hardware front, DMG MORI’s regenerative braking technology reduces energy consumption by 25% during spindle deceleration, aligning with EU carbon neutrality directives and lowering manufacturers’ operational costs. These advancements lay the foundation for robust growth in the four-axis CNC milling market, with Global Market Insights projecting a valuation of $83.756 billion by 2030.

Regional Market Dynamics for 4-Axis CNC Milling

North America is dominated by aerospace applications, accounting for 32% of global demand. Boeing and Lockheed Martin procure 4-axis CNC milling systems for turbine blade and structural component manufacturing. The region’s focus on next-generation military aircraft and commercial aviation modernization drives investment in high-torque horizontal machining centers.

Europe leads in automotive precision machining, with Germany’s automotive sector consuming 41% of regional four-axis CNC milling equipment for producing transmission housings and motor components. Italian and French manufacturers specialize in compact vertical four-axis CNC milling centers for luxury automotive interior parts, supported by the EU’s “Industry 5.0” initiative promoting smart factory integration.

Market segmentation reveals vertical 4-axis CNC milling centers command a 58% share due to their versatility in small-to-medium batch production, while horizontal models dominate high-volume automotive production lines with their pallet-changing capabilities. Leading manufacturers including Mazak, Haas, and DMG MORI maintain technological leadership through integrated automation solutions, capturing 67% of the high-end four-axis CNC milling market.

Quality Control of 4-Axis CNC Milling and International Standards

The quality control system for 4-axis CNC milling adopts international standards as its core framework, forming a closed-loop process of “standardization-inspection-application.” ISO 230-1:2012 (International Standard for Machine Tool Geometric Accuracy) specifies geometric accuracy requirements: linear axis positioning accuracy P ≤ 0.015 mm, rotary axis angular error ≤ ±0.001°, with trajectory perpendicularity error evaluated using least squares or endpoint methods. In contrast, the American National Standards Institute (ANSI) B5.54 (Machine Tool Performance Standard) establishes a performance evaluation system incorporating acceptance testing and periodic verification through standardized terminology and environmental impact handling methods, promoting comparability among four-axis CNC milling equipment.

Precision inspection relies on high-end metrology equipment. For instance, the Hexagon Tigo 565 CMM achieves repeatability accuracy of ±0.003 mm in aluminum alloy part inspection. When paired with a stylus-type profilometer, it enables surface roughness measurement ranging from Ra 0.025 to 12.5 μm. The aerospace sector commonly adopts ISO 2768-f tolerance standards, with tolerances of ±0.1 mm for dimensions ranging from 6 to 30 mm. Critical features require CPK ≥ 1.33, and factory acceptance rates must meet ≥99.5% (PPM ≤ 5000).

In practical applications, the Mazak VCN-530C utilizes VCS Complete error compensation technology to elevate 4-axis CNC milling positioning accuracy to ±0.001 mm, meeting IT5 precision requirements. For quality system certification, ISO 9001:2015 serves as the baseline requirement. Aerospace sectors additionally mandate AS9100 compliance, while the automotive industry adopts IATF 16949.

Core Control Metrics for 4-Axis CNC Milling

- Positioning Accuracy: Linear axes ≤ ±0.015 mm, rotary axes ≤ ±0.001° (ISO 230-1)

- Surface Finish: Ra 0.025–3.2 μm, crack-free, pit depth ≤ 0.01 mm

- Process capability: Critical dimension CPK ≥ 1.33, first article inspection pass rate ≥ 99%

The inspection process implements a three-tier verification system: initial part inspection confirms the 4-axis CNC milling process parameters, hourly patrol inspections monitor dimensional stability, and final part inspection analyzes trend changes. For example, the dimensional tolerance of liquid-cooled seal blocks is controlled within 0.03 mm, with a runout ≤0.02 mm during clamping, ensuring consistency in mass production.

Summary

If you’re currently seeking an exceptional four-axis machining service provider offering comprehensive advantages in quality standards, processing costs, and delivery speed, contact Weldo. Bring your design drawings, and we’ll promptly provide a quote to assist with your project cost calculations.