Characteristics and Selection Strategies for CNC-Machined Aluminum Parts

CNC machined aluminum parts have become a common material in CNC precision manufacturing due to their high strength-to-weight ratio, corrosion resistance, and excellent machinability. When selecting materials for custom precision components, we must follow a “performance-to-application matching” logic, balancing three key factors: strength, cost, and machining difficulty (CNC machining precision).

Performance Comparison of Mainstream Alloys

Key parameters for three typical alloys (ASTM B221 standard) are shown in the table below:

| Alloy Type | Tensile Strength (MPa) | Density (g/cm³) | Machinability | Main Application Fields |

| 6061-T6 | 290 | 2.70 | Excellent | Automotive, General Engineering |

| 7075-T6 | 572 | 2.81 | Medium | Aerospace Structural Components |

| 2024 | 470 | 2.78 | Good | High-Strength Connectors |

Three Key Factors for Material Selection:

1. Strength Priority: Aerospace applications require 7075-T6‘s tensile strength of 572 MPa;

2. Cost Control: Recycled aluminum reduces raw material costs by 30%, suitable for automotive lightweight components;

3. Machining Efficiency: 6061 offers superior machinability compared to 7075, minimizing tool wear and processing time.

Engineers must prioritize corrosion-resistant alloys for marine environments and leverage 6061’s machining stability for high-precision components, achieving the optimal balance between material performance and manufacturing costs.

CNC Machining of Aluminum Parts: Processes and Technological Innovation

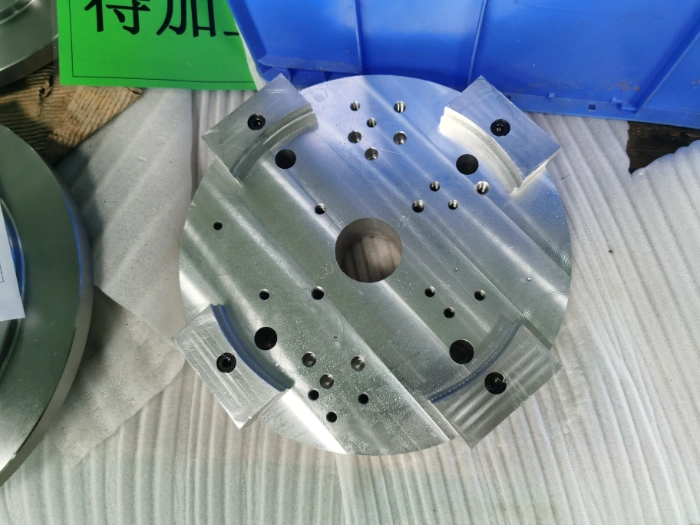

CNC machining of aluminum parts and technological innovation are undergoing profound transformation centered on the three-dimensional framework of “Precision-Efficiency-Intelligence.” In the precision enhancement dimension, 5-axis machining achieves integrated forming of complex surfaces through the coordinated movement of X, Y, Z linear axes and A, B rotary axes. Its ±0.003mm positioning accuracy and C-axis 360° continuous rotation capability reduce clamping errors by 70% compared to traditional three-axis machining (±0.01mm accuracy). Taking the machining of aerospace 7075 aluminum alloy wing spars as an example, five-axis equipment can complete complex internal cavity structures in a single setup, meeting ±0.005mm tolerance requirements. When equipped with a 24,000rpm high-speed spindle and PCD tools, machining centers achieve a mirror-like surface finish with a roughness Ra of 0.2μm, while boosting cutting efficiency by 40% compared to three-axis equipment.

Technical Comparison: Compared to traditional three-axis equipment (±0.01mm accuracy, 8000rpm spindle), the five-axis machining center (±0.003mm positioning accuracy, 24000rpm spindle) delivers 70% higher precision, 40%-50% greater efficiency, and 60% fewer clamping operations when machining complex aluminum surfaces.

CNC Machining of Aluminum Components: Applications and Case Studies

Leveraging advantages such as material lightweighting, high machining precision, and strong process adaptability, CNC machined aluminum components excel in critical sectors including aerospace, new energy vehicles, and consumer electronics.

Aerospace Sector: Integrated Breakthroughs in High-Strength Materials and Five-Axis Machining

The aerospace sector imposes stringent requirements on structural components for both strength (tensile strength ≥500 MPa) and lightweighting (weight reduction ≥20%). 7075-T6 aluminum alloy emerges as the core material selection, offering tensile strength of 572 MPa and fatigue strength of 160 MPa. Combined with 5-axis machining technology, it enables the integrated forming of complex components. Case Study: Critical structural components for the C919 and ARJ21 aircraft—including wing panels and spars—were produced via monolithic milling instead of traditional assembly methods. This approach reduced component weight by 30% while maintaining machining tolerances within ±0.02 mm. This field also pushes process boundaries through deep-hole machining of titanium-aluminum composites (diameter-to-depth ratio >10). Utilizing internal-cooling drills (8 MPa pressure) with G83 peck drilling cycles ensures hole wall surface roughness Ra≤1.6 μm.

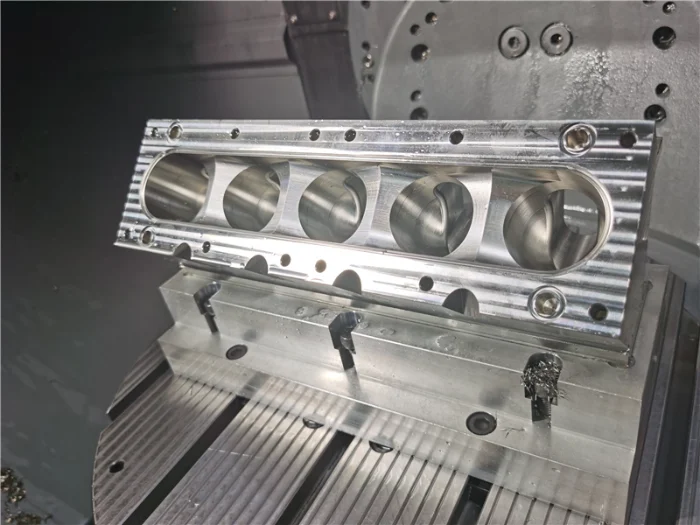

New Energy Vehicle Sector: Synergistic Optimization of Structural Safety and Precision Machining

Load-bearing components like battery housings and motor parts in new energy vehicles must maintain structural stability under vibration conditions. Recycled aluminum alloys, with a tensile strength of 310 MPa and 12% elongation, have become the mainstream material. Machining employs high-speed spindles (24,000 rpm) with 5-axis simultaneous milling to achieve mirror-finish T-slot machining (Ra 0.4 μm) on battery trays. Microchannel structural design further enhances the casing’s thermal conductivity by 15%. Processing efficiency for automotive lightweight components (e.g., Al-6061 T6 bases) triples compared to traditional methods. After adopting this technology, one automaker achieved a 45 kg reduction in aluminum component weight per vehicle, increasing driving range by 8%.

Consumer Electronics Sector: Customized Integration of Surface Treatment and Flexible Manufacturing

Demand for aesthetic quality and rapid iteration in consumer electronics drives widespread adoption of 6063 aluminum alloy. Its excellent anodizing performance (film thickness uniformity ±5%) enables diverse finishes like matte and high-gloss. Modular flexible production lines enable small-batch customization. A case study from a 3C company shows production line changeover time reduced to 10 minutes, supporting over 10 product types including smartphone midframes (tolerance ±0.01 mm) and smart wearable casings (ultra-thin walls 0.3 mm). Small-batch order delivery cycles were compressed from 15 days to 3 days.

Case Study Summary: 3 Key Elements

Aerospace: 7075-T6 (572 MPa) + Five-axis integrated forming (30% weight reduction)

New Energy Vehicles: Recycled Aluminum Alloy (310 MPa) + 24,000 rpm High-Speed Milling (Ra 0.4 μm)

Consumer Electronics: 6063 (Anodizing Compatible) + Flexible Production Line (10-Minute Tool Change)

Quality Control of CNC-Machined Aluminum Parts and the International Standards System

International Tolerance Standards System

The ISO 2768 series serves as the core tolerance framework for CNC-machined aluminum parts. The 2025 edition further clarifies unspecified tolerance specifications, divided into ISO 2768-1 (linear/angular dimensions) and ISO 2768-2 (geometric tolerances). Linear dimensional tolerances are categorized into three grades: f (fine), m (medium), and c (coarse), each with distinct typical applications: Aerospace sectors universally adopt f-grade tolerances due to structural safety requirements; general mechanical processing primarily uses m-grade to balance precision and cost; c-grade is suitable for scenarios with lower fit requirements, such as heavy equipment. The numerical values for linear dimensional tolerances (0.5–30 mm range) are shown in the table below:

| Accuracy grade | Size range(mm) | Allowable tolerance(±mm) |

| f(Precision) | 0.5 – 3 | 0.05 |

| 3 – 6 | 0.05 | |

| 6 – 30 | 0.1 | |

| m(Medium) | 0.5 – 3 | 0.1 |

| 3 – 6 | 0.1 | |

| 6 – 30 | 0.2 | |

| c(Coarse) | 0.5 – 3 | 0.2 |

| 3 – 6 | 0.3 | |

| 6 – 30 | 0.5 |

High-Precision Inspection Technology

The dimensional tolerances of CNC-machined aluminum components rely on advanced inspection equipment:

Laser interferometers utilize laser wavelength standards to achieve positioning accuracy calibration of ±0.5 μm, effectively quantifying machine positioning errors (typically required to be ≤ ±0.005 mm);

Coordinate measuring machines (CMMs) utilize contact or optical probes to perform full-dimension inspection of complex surfaces and inaccessible locations, controlling repeatability errors to ±0.002 mm. This meets geometric tolerance verification requirements for precision components like aerospace engine blades. Inspection protocols must cover positioning accuracy, repeat positioning accuracy (≤ ±0.003 mm), and thermal stability testing to ensure long-term machining consistency.

Intelligent Process Control Solutions

Process control achieves error compensation through hardware optimization combined with intelligent algorithms:

The thermal deformation compensation system dynamically corrects machine structural deformation based on real-time temperature sensor data, reducing errors by 40% after implementation on a machining center;

AI vision inspection technology identifies surface defects via deep learning algorithms with a response time of just 0.5 seconds and a detection rate of 99.9%.

Standard – Process Integration Key Points: 5-axis machining achieves positioning accuracy within ±0.005 mm through real-time error compensation (thermal deformation, tool wear) and high-precision closed-loop detection, meeting aerospace F-grade tolerances. For general machinery requiring M-grade tolerances, optimized cutting parameters (feed rates 500–1000 mm/min) balance efficiency and precision.

Difference between cnc machined aluminum part and steel part

In CNC material selection, aluminum alloys dominate lightweight, high-precision applications due to their low weight, machinability, and corrosion resistance. Alloy steels remain irreplaceable in extreme conditions owing to their high strength and heat resistance. This differentiation stems from matching material properties with processing requirements.

CNC Machining Characteristics Comparison: Aluminum Alloy vs. Alloy Steel

Aluminum alloy’s core advantages in CNC machining lie in dual dimensions: material machinability and functional adaptability. With a density of only 2.7–2.8 g/cm³ (approximately one-third that of steel), machining forces are significantly reduced. Tool wear rates are slowed by 40%–60% compared to machining alloy steel. Combined with excellent chip breaking properties, this enables machining efficiency 2–3 times higher than that of alloy steel. Simultaneously, the natural oxidation of aluminum alloys forms an Al₂O₃ protective layer (approximately 0.1 μm thick), granting superior corrosion resistance compared to untreated alloy steel, particularly in humid or marine environments. Furthermore, its high specific strength (e.g., 7075-T6 boasts a strength of 572 MPa at a density of only 2.81 g/cm³) and 100% recyclability (recycling energy consumption is just 5% of primary aluminum) further solidify its application advantages.

Limitations of aluminum alloys: Their hardness generally falls below 150 HB (approximately 95 HB for 6061-T6), with a melting point of only 660°C. Their thermal expansion coefficient (23.1 × 10⁻⁶/°C) exceeds that of steel by more than twofold, rendering them inadequate for high-impact applications (e.g., heavy machinery gears), sustained high-temperature environments (e.g., engine combustion chambers), or extreme load scenarios.

Alloy steels fill the application gap for precision aluminum alloy components with their superior mechanical properties. Their tensile strength at room temperature can exceed 1000 MPa (e.g., 4140 alloy steel), with a melting point around 1400°C. Combined with quenching and tempering processes, they can achieve hardness above HRC 50, making them suitable for manufacturing critical components like gears and molds subjected to alternating loads. However, their high density (7.85 g/cm³) increases cutting forces during machining, reducing tool life by 30%–50%. Additional surface treatments (e.g., zinc or chrome plating) are required to enhance corrosion resistance, resulting in overall machining costs 20%–40% higher than aluminum alloys.

Application Segmentation and Synergy

Aluminum alloys and alloy steels exhibit distinct application scenarios. Aluminum alloys dominate aerospace (wing components, landing gear), automotive (chassis parts, motor housings), and consumer electronics (laptop casings, heat sinks) due to their balanced lightweight-precision-efficiency profile. For instance, the Airbus A350 fuselage utilizes 2024 and 7075 aluminum alloys, achieving a 15% weight reduction while maintaining structural integrity. The Tesla Model 3 battery casing employs 6061-T6 aluminum alloy, where CNC machining enhances structural precision to ±0.02 mm.

Alloy steels focus on high-strength, wear-resistant, and high-temperature applications, such as heavy machinery (excavator gearboxes), mold manufacturing (cold work tool steel D2), and energy equipment (turbine blades). Typical examples include: W18Cr4V high-speed steel milling cutters achieve HRC 62–65 hardness, offering over 10 times the service life of aluminum alloy tools.

Common CNC-Machined Aluminum Materials: Classification and Properties

Aluminum alloys form diverse systems through alloying element control. The following six representative alloys cover over 90% of CNC machining applications:

| Aluminum Alloy Grade | Main Alloying Elements | Core Properties | Typical Application Scenarios |

| 2024 – T3 | Cu (3.8% – 4.9%) | Tensile strength 440 MPa, excellent fatigue strength (145 MPa@10⁷ cycles), good machinability | Aircraft fuselage skin, wing stringers, missile cabin |

| 5052 – H32 | Mg (2.2% – 2.8%) | Density 2.68 g/cm³, elongation 15%, seawater corrosion resistance (no red rust after 5000 hours salt spray test) | Ship decks, fuel tanks, welded structural components |

| 6061 – T6 | Mg (0.8% – 1.2%), Si (0.4% – 0.8%) | Yield strength 276 MPa, anodizable, thermal conductivity 167 W/(m·K) | Bicycle frames, automobile wheels, electronic heat sinks |

| 6063 – T5 | Mg (0.45% – 0.9%), Si (0.2% – 0.6%) | Elongation after fracture 8%, easy extrusion forming, surface finish Ra 1.6 μm | Architectural door and window profiles, furniture frames, LED lamp housings |

| 7075 – T651 | Zn (5.1% – 6.1%), Mg (2.1% – 2.9%) | Hardness 150 HB, elastic modulus 71 GPa, plane strain fracture toughness 29 MPa·m^(1/2) | Aero engine blades, racing car suspension arms, high-precision molds |

| 6082 – T6 | Si (0.7% – 1.3%), Mg (0.6% – 1.0%) | Strength close to 6061, 15% higher cutting speed, welding joint efficiency 85% | Construction machinery structural parts, automobile drive shafts, robot joints |

These alloys achieve targeted performance design through optimized compositions: the 2000 series enhances strength with copper, the 7000 series pushes specific strength limits using a zinc-magnesium-copper system, while the 6000 series balances machinability and corrosion resistance via magnesium-silicon phases. Together, they form the foundational material library for CNC machining.

Selection Strategy: Prioritize strength requirements (7075 > 2024 > 6082 ≈ 6061 > 5052 > 6063), then integrate corrosion resistance (5052 > 6063 > 6061 > 2024 > 7075) and machining cost (6063 < 6061 < 5052 < 6082 < 2024 < 7075) for comprehensive decision-making.

The following is the steel part CNC materials commonly used in our weldo machining center and their respective characteristics and application comparison information:

| International Standard Grade (ASTM) | Main Alloying Elements | Core Properties | Typical Applications |

| 5140 | Cr (0.8-1.1%) | Tensile Strength 980MPa, Hardness HRC28-32, Good Hardenability | Drive Shafts, Gears, Bolts |

| 4140 | Cr (0.9-1.2%), Mo (0.15-0.25%) | Tensile Strength 1080MPa, Hardness HRC30-35, High Strength & Fatigue Resistance | Automotive Half-Shafts, Wind Power Bolts, Oil Drill Pipes |

| 8620H | Ni (0.4-0.7%), Cr (0.4-0.6%), Mn (0.7-0.9%) | Case-hardened Surface Hardness HRC58-62, Good Core Toughness | Automotive Transmission Gears, Reducer Gears |

| 4130 | Cr (0.8-1.1%), Mo (0.15-0.25%) | Tensile Strength 850MPa, Hardness HRC25-30, Excellent Weldability | Aerospace Structural Components, Hydraulic Pipes, Bicycle Frames |

| 4041 | Cr (0.7-0.9%), Mo (0.2-0.3%) | Tensile Strength 1100MPa, Hardness HRC32-38, Good Impact Resistance | Heavy-Duty Drive Shafts, Machine Tool Spindles, Mining Machinery Parts |

| H13 | Cr (4.75-5.5%), Mo (1.1-1.75%), V (0.8-1.2%) | Impact Toughness ≥30J/cm², High Thermal Strength | Hot Forging Dies, Die Casting Molds |

Conclusion

Through precise alignment of material properties with processing requirements, aluminum alloys continue to expand their applications in CNC machining, while alloy steels maintain their core position in high-strength scenarios where they remain irreplaceable. Together, they form the twin pillars of modern manufacturing materials. If you wish to customize your own CNC-machined aluminum parts, click to contact Weldo’s professional customer service team for the latest quote.