CNC (Computer Numerical Control) machining is a technology that uses computer programs to control machine tools to achieve automated precision manufacturing. It is widely used in the production of complex parts in aerospace, automotive, medical and other fields. Its machining process covers the entire cycle from digital modeling to finished product delivery. The precise execution of each link plays a decisive role in the final product quality. The CNC machining steps are as follows:

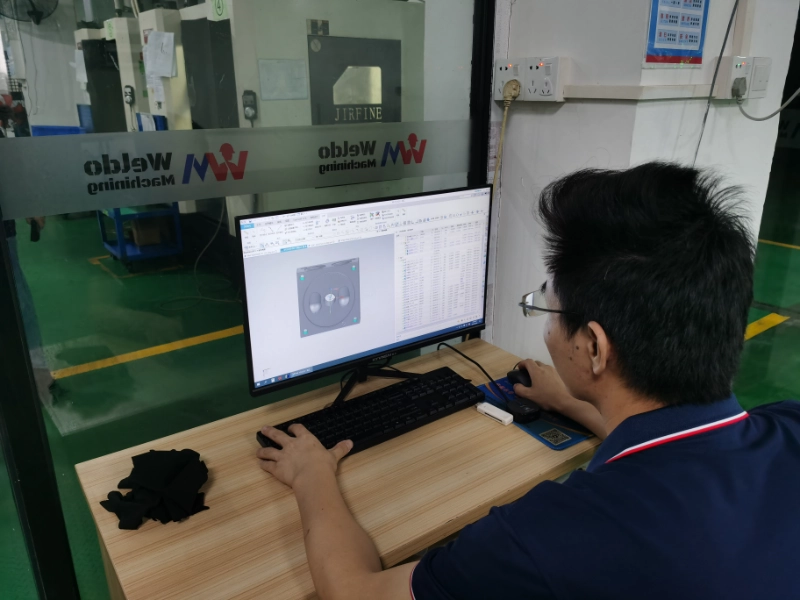

Design Phase: CAD Modeling

Step: Use CAD (Computer-Aided Design) software (such as SolidWorks or AutoCAD) to create a 3D model or 2D drawing to clearly define the part’s geometry, dimensions, tolerances, and surface finish requirements.

Key Point: The design must be process-compliant, avoiding difficult-to-machine features such as excessively small corner radii and deep cavities.

Process Planning: CAM Programming

Step: Import the CAD model into CAM (Computer-Aided Manufacturing) software (such as Mastercam or UG) to generate the tool path (G-code).

Tool Selection: Select a milling cutter, drill, or turning tool based on the material hardness and machining accuracy.

Parameter Setting: This includes cutting speed, feed rate, spindle speed, and depth of cut.

Simulation Verification: Use software to simulate the machining process to check for collisions, overcutting, and other issues. Key Point: Optimize tool paths to reduce machining time while ensuring surface quality.

Material Preparation and Fixturing

Steps:

Material Selection: Select metal (aluminum, steel), plastic, or composite material based on part performance requirements (such as strength and corrosion resistance).

Clamping and Positioning: Use a vise, chuck, or specialized fixture to secure the material and ensure machining stability.

Tool Setting: Determine the workpiece coordinate system origin using a probe or manual method (G54-G59).

Key Point: Avoid deformation during clamping; tool setting accuracy directly affects machining dimensions.

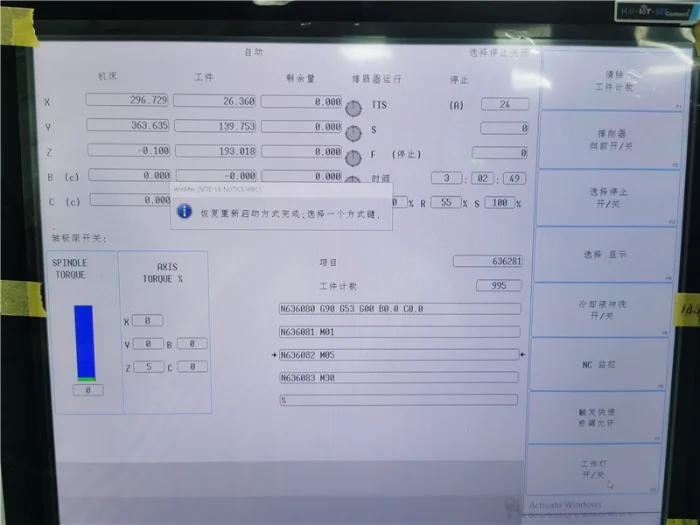

CNC Machine Setup

Steps:

Program Input: Upload the G-code generated by the CAM program to the machine controller.

Tool Installation: Change the tool according to the program requirements and set the tool compensation value.

Test Run: Run the program dry (without material) to verify correct machine motion.

Key Point: Ensure that the machine coordinate system and the workpiece coordinate system are consistent to avoid program errors.

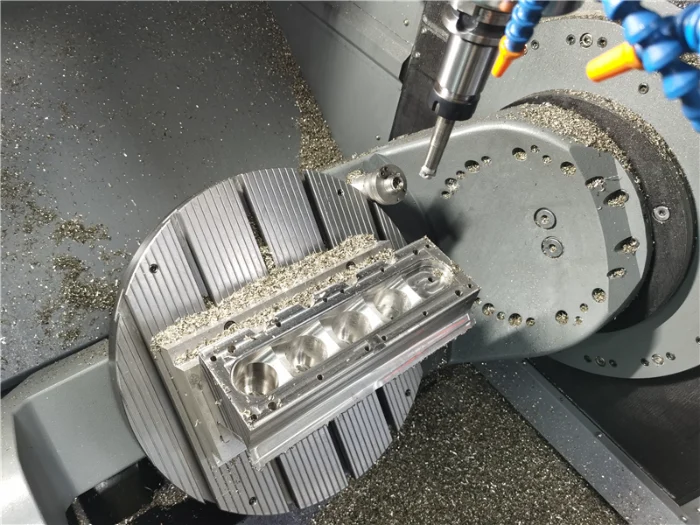

Roughing cnc machining

Purpose: Quickly remove the majority of the excess material and achieve a near-net shape. Steps:

Use a large-diameter tool (such as an end mill) to perform layered cutting.

Allow a finishing allowance (typically 0.1-0.5mm).

Key Point: Control cutting forces to avoid vibration and maximize efficiency.

Semi-finishing cnc machining

Purpose: Further correct the shape in preparation for finishing.

Steps:

Use a smaller diameter tool or a ball-end milling cutter to machine the curved surface.

Reduce the depth of cut to improve surface quality.

Key Point: Ensure uniform stock allowances to avoid overcutting during finishing.

Finishing cnc machining

Purpose: Achieve final dimensions and surface finish requirements.

Steps:

Use a small diameter tool or a fine engraving tool for micro-cutting.

Control the feed rate and cutting speed to reduce tool wear.

Key Point: Dimensional inspection is usually required after finishing, and additional machining is performed if necessary.

Hole making and Threading machining

Steps:

Drilling: Use a center drill to locate the hole, then change the drill bit to complete a through hole or blind hole.

Reaming/Boring: Improve hole diameter accuracy and surface quality.

Tapping: Use a tap to create internal threads.

Key Point: Holes must be perpendicular, and threads must meet tolerances.

Deburring and Surface Treatment

Steps:

Manual Deburring: Use files and sandpaper to remove edge burrs.

Machine Deburring: Use automated methods such as vibration grinding and sandblasting.

Surface finishes: Anodizing, electroplating, and painting may be performed as required.

Key Point: Deburring must be thorough to avoid affecting assembly or functionality.

Quality Inspection

Steps:

Dimensional Inspection: Use calipers, micrometers, and coordinate measuring machines (CMMs) to verify dimensions.

Surface Inspection: Visually inspect or measure surface quality using a roughness tester.

Functional Testing: Perform performance tests (such as sealing and strength) after assembly.

Key Point: Testing must cover critical dimensions and tolerances to ensure a satisfactory pass rate.

Packaging and Delivery

Steps: Clean parts, apply anti-rust oil (for metal parts), and package according to customer specifications (e.g., foam boxes or cartons).

Key Point: Packaging must be shock- and moisture-proof to prevent damage during transportation. Core Advantages of CNC Machining

High Precision: Repeatable positioning accuracy reaches ±0.001mm.

Efficiency: Automated machining reduces manual intervention, making it suitable for high-volume production.

Flexibility: Rapid program switching allows for adapting to high-mix, low-volume demands.

By strictly adhering to these steps, CNC machining enables efficient and precise manufacturing from design to finished product, meeting the demands of complex parts in aerospace, automotive, and medical fields.

Summary of CNC Machining Steps

CNC machining achieves high-precision part manufacturing through a systematic process. The core process includes: CAD modeling to define part geometry, CAM programming to generate tool paths and optimize parameters, clamping and positioning to ensure machining stability, layered cutting (roughing, semi-finishing, and finishing) to gradually approach final dimensions, hole and thread machining to complete the connection structure, deburring to enhance surface quality, and finally, three-dimensional coordinate inspection to verify dimensional accuracy. This closed-loop process, combining automated control and precision craftsmanship, is applicable to a wide range of scenarios, from single-piece customization to mass production, and has become a core technology in modern manufacturing.

FAQ of cnc machining steps

What preparations are required before CNC machining?

CAD model design, CAM programming to generate G-code, material selection, and clamping strategy development are required, as well as ensuring alignment between the machine tool coordinate system and the workpiece coordinate system.

What are the main differences between roughing and finishing?

Roughing quickly removes most of the stock (leaving 0.1-0.5mm stock) using large-diameter tools. Finishing uses small-diameter tools for micro-cutting, maintaining a surface roughness of Ra ≤ 0.8μm.

How can vibration be avoided during CNC machining?

Optimize cutting parameters (reduce feed rate, reduce cutting depth), use vibration-damping tools, adjust clamping rigidity, or preemptively avoid resonant paths through CAM simulation.

What are the causes of hole diameter deviations during CNC machining?

Tool wear, insufficient spindle speed, abnormal coolant supply, loose workpiece clamping, or incorrect hole machining parameter settings in the CAM program.

What are the advantages of 5-axis CNC machining over three-axis machining?

5-axis machines enable multi-angle machining of complex surfaces in a single clamping, reducing clamping times, improving precision, and shortening machining cycles. They are suitable for special-shaped parts such as aircraft blades.

How can I resolve substandard surface roughness after CNC machining?

Check tool wear, adjust finishing parameters (reduce feed rate, reduce cutting allowance), replace with a higher-precision tool, or add a polishing step.

How can I balance CNC machining cost and efficiency for small-batch production?

Use modular fixtures to reduce changeover time, optimize tool paths to minimize idle travel, select universal tools to reduce inventory costs, and quickly generate programs using CAM software.

How can automated inspection and feedback be achieved in CNC machining?

Integrate in-process measurement probes (such as infrared or laser probes) to collect dimensional data in real time and provide feedback to the control system, automatically adjusting machining parameters or triggering compensation routines.