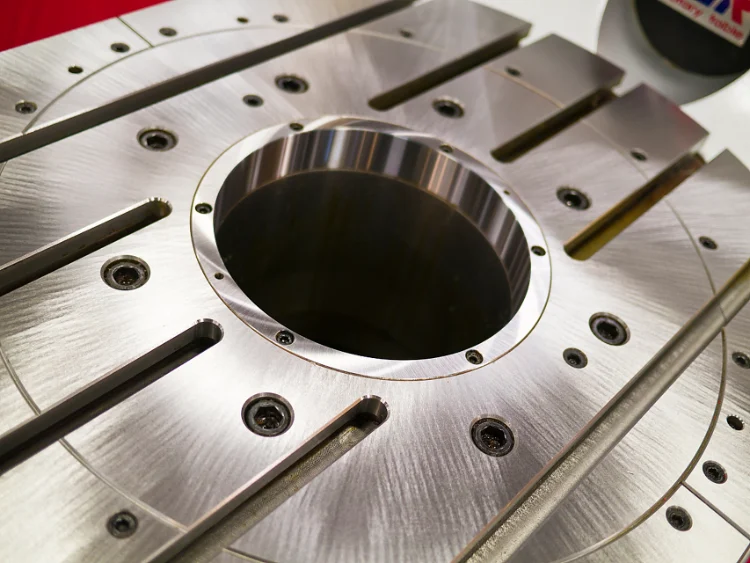

Understanding the real magnesium cnc machining price is essential for engineers, procurement managers, and product designers working on lightweight components for aerospace, automotive, robotics, medical devices, and electronics. Magnesium is one of the easiest metals to machine and offers an exceptional strength-to-weight ratio, but its cost varies significantly based on alloy choice, machining complexity, tolerance requirements, and finishing needs. This guide breaks down cost factors, material options, and practical applications to help you estimate your machining budget more accurately.

Key Factors That Influence Magnesium CNC Machining Price

Because magnesium is highly machinable, many users expect low machining prices. However, the actual magnesium cnc machining price depends on several technical and production variables.

1. Material Grade and Raw Magnesium Cost

Different magnesium alloys have different pricing and machining properties.

Common alloys that affect magnesium cnc machining cost include:

- AZ31: Low-cost, excellent machinability

- AZ61: Higher strength, slightly more expensive

- AZ91: Strong corrosion resistance, common in electronics

- WE43: Premium alloy used in aerospace with the highest price

For custom magnesium cnc machining, choosing the correct alloy determines not only performance but also budget.

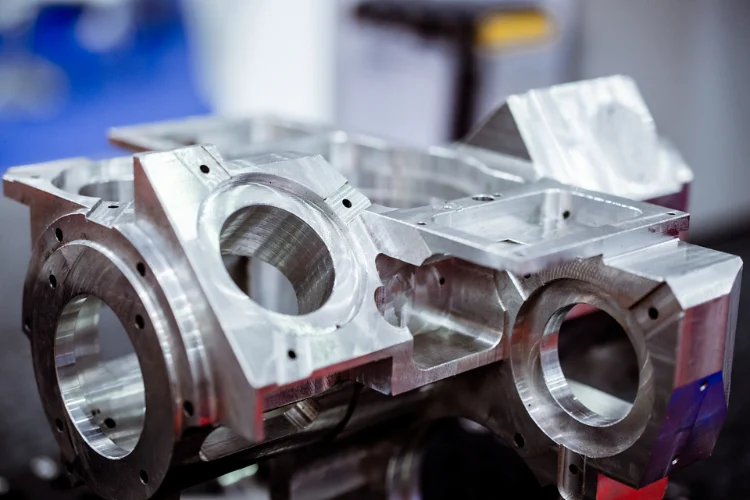

2. Machining Complexity

Parts with deep pockets, ultra-thin walls, or 5-axis machining requirements increase machining time.

Key cost drivers:

- Number of toolpaths

- Multi-sided machining

- Tight internal geometries

- High-speed cutting requirements

More complexity = higher magnesium cnc machining cost.

3. Dimensional Tolerances

The tighter the tolerance, the higher the magnesium cnc machining price.

Typical tolerance categories:

- ±0.05 mm → standard machining, low cost

- ±0.02 mm → precision machining, moderate cost

- ±0.005–0.01 mm → high-precision aerospace-grade machining, premium pricing

Magnesium is stable, but precision requirements raise the final machining budget.

4. Finishing Requirements

Magnesium is soft and requires protective finishing:

- Anodizing

- Chemical conversion coating

- Powder coating

- Polishing & edge finishing

Adding these processes increases magnesium cnc machining price, especially for high-end consumer electronics or aerospace components.

5. Batch Size

Cost per unit decreases significantly when ordering larger quantities.

Typical price trends:

| Quantity | Average Magnesium CNC Price |

|---|---|

| 1–10 pcs | highest cost per unit |

| 20–100 pcs | stable cost reduction |

| 100+ pcs | lowest price due to optimized setup |

For manufacturing companies, bulk orders lead to the best magnesium cnc machining cost.

Price Range for Magnesium CNC Machining

Below is a general estimate for common magnesium components:

| Part Type | Estimated Price Range |

|---|---|

| Simple brackets, blocks | $20–$60 |

| Electronics housings | $40–$150 |

| Automotive components | $80–$200 |

| Aerospace-grade parts | $120–$350+ |

| Custom magnesium prototypes | $60–$300 |

Actual magnesium cnc machining price will vary depending on project specifications.

Material Options for Magnesium CNC Machining

Choosing the correct magnesium alloy is critical for balancing performance and cost.

AZ31 Magnesium Alloy

Key Features

- Excellent machinability

- Good strength-to-weight ratio

- Cost-effective

Applications

- General prototypes

- Consumer electronics

- Lightweight covers and plates

Ideal for standard custom magnesium cnc machining projects.

AZ61 Magnesium Alloy

Key Features

- Higher tensile strength

- Improved corrosion resistance

- Stable mechanical properties

Applications

- Automotive brackets

- Sports equipment

- Industrial tool bodies

Better performance but slightly higher magnesium cnc machining price.

AZ91 Magnesium Alloy

Key Features

- Widely used alloy with strong corrosion resistance

- Excellent castability and consistency

Applications

- Laptop frames

- Structural housings

- Mechanical device components

Best overall balance of machining cost and durability.

WE43 Magnesium Alloy

Key Features

- Exceptional high-temperature performance

- Aerospace-grade alloy

- Highest strength among common magnesium grades

Applications

- UAV frames

- Satellite structures

- High-performance mechanical parts

Premium alloy = premium magnesium cnc machining price.

Applications That Influence Magnesium CNC Machining Cost

Electronics & Consumer Devices

- Laptop and tablet housings

- Camera bodies

- Drone frames

Lightweight prototypes reduce testing cost and improve handling.

Automotive and Motorsports

- Steering wheel cores

- Transmission parts

- Dashboard support structures

Magnesium helps improve vehicle fuel efficiency and performance.

Aerospace & UAV Components

- Frame structures

- Brackets

- Cooling housings

High precision increases magnesium cnc machining cost, but weight savings are significant.

Industrial Tools & Machinery

- Ergonomic handles

- Power tool frames

- Vibration-sensitive components

Magnesium’s damping properties make it perfect for these designs.

How to Reduce Magnesium CNC Machining Price

Use standard tolerances

Avoid ultra-tight tolerances unless necessary.

Choose cost-effective alloys like AZ31 or AZ91

They provide excellent machinability and low raw material cost.

Combine parts where possible

Reducing the number of machined components lowers overall machining time.

Optimize 3D models

Avoid unnecessary thin walls, deep pockets, or small-radius internal corners.

Request Magnesium CNC Machining Price — Contact Weldo Machining

To achieve stable quality and competitive cost, choosing the right machining partner is crucial. As a professional magnesium CNC manufacturer, Weldo Machining provides reliable magnesium cnc machining price evaluations, engineering consultation, and multi-alloy machining support. From lightweight prototypes to high-precision aerospace components, our team delivers accurate machining, fast turnaround, and consistent quality at cost-effective rates.

Contact us today for detailed magnesium CNC machining pricing and technical guidance tailored to your project.

FAQ of cnc machining magnesium price

What affects magnesium CNC machining price the most?

Key factors include alloy selection, tolerances, machining complexity, finishing processes, and batch size.

Which magnesium alloy is the most cost-effective?

AZ31 and AZ91 are the most commonly used due to excellent machinability and low material cost.

Is magnesium cheaper to machine than aluminum?

Yes, magnesium cuts faster and produces less tool wear, making machining cost lower in many cases.

Does finishing increase CNC machining cost?

Yes—anodizing, conversion coating, and polishing all increase total magnesium cnc machining cost.