En la selección de materiales, la fabricación industrial y el reciclado de metales, mucha gente se pregunta: ¿Es el aluminio un metal magnético?

La respuesta es muy clara: el aluminio no es un metal magnéticopero un típico metal no magnético. Para entender bien esta conclusión, es necesario examinar la definición de metales magnéticos, las propiedades materiales del aluminio y sus aplicaciones reales en ingeniería.

¿Qué son los metales magnéticos?

Los metales magnéticos se refieren generalmente a metales o materiales metálicos que puede ser claramente atraído por un imán y puede conservar el magnetismo después de retirar un campo magnético externo. Estos materiales se utilizan principalmente en sistemas electromagnéticos, de potencia y de control.

Metales magnéticos comunes y breves descripciones

- Hierro (Fe): El metal magnético más típico, con un magnetismo fuerte y estable, muy utilizado en motores, transformadores, núcleos magnéticos y estructuras mecánicas.

- Níquel (Ni): Tiene propiedades magnéticas estables y se utiliza comúnmente en aleaciones especiales, materiales para baterías y ciertos componentes funcionales magnéticos.

- Cobalto (Co): Mantiene el magnetismo incluso a altas temperaturas y se utiliza a menudo en imanes de alto rendimiento y materiales relacionados con la industria aeroespacial.

- Acero al carbono y acero de baja aleación: Principalmente a base de hierro y generalmente magnético, comúnmente utilizado en equipos electromagnéticos y componentes mecánicos.

- Acero inoxidable ferrítico / martensítico: Estos aceros inoxidables presentan un magnetismo perceptible y se utilizan ampliamente en equipos industriales y piezas estructurales (no todos los aceros inoxidables son amagnéticos).

El valor fundamental de los metales magnéticos reside en su respuesta magnética y capacidad de conversión de energía.

¿Es el aluminio un metal magnético?

No. El aluminio no es un metal magnético.

Desde el punto de vista de la ciencia de los materiales, el aluminio se clasifica como un metal no magnético. Es físicamente paramagnéticolo que significa que sólo muestra una respuesta extremadamente débil y temporal en campos magnéticos fuertes, que es insignificante en aplicaciones prácticas de ingeniería.

Como resultado, el aluminio no se pega a los imanes y no puede magnetizarse en el uso cotidiano o industrial.

¿Por qué se clasifica el aluminio como metal no magnético?

La estructura atómica del aluminio determina que no pueden formar dominios magnéticos estables:

- Su disposición electrónica no admite la alineación del momento magnético a largo plazo

- Carece de la estructura interna necesaria para el ferromagnetismo

- No conserva el magnetismo una vez retirado el campo magnético

Por estas razones, el aluminio se considera sistemáticamente un metal no magnético en la práctica de la ingeniería.

¿Reacciona el aluminio en un campo magnético?

En algunas situaciones, puede parecer que el aluminio "reacciona" a un campo magnético, lo que da lugar a malentendidos. Esto se debe principalmente al efecto de corriente parásita.

Cuando el aluminio se mueve rápidamente en un campo magnético intenso, su elevada conductividad eléctrica provoca la formación de corrientes parásitas que generan fuerzas electromagnéticas opuestas. Esto puede aparecer como resistencia o repulsión, pero es un fenómeno de inducción electromagnética...no verdadero magnetismo.

¿Cómo se puede hacer magnético el aluminio?

Debe quedar claro que el aluminio puro no puede convertirse en un verdadero metal magnético en términos de naturaleza material. Sin embargo, en la práctica de la ingeniería, las funciones relacionadas con el magnetismo pueden lograrse de las siguientes maneras indirectas:

- Introducción de elementos magnéticos en aleaciones de aluminio

La adición de hierro, níquel o cobalto a las aleaciones de aluminio puede formar fases magnéticas localizadas y producir ligeras respuestas magnéticas. En este caso, el magnetismo procede de los propios elementos magnéticos, mientras que la matriz de aluminio sigue siendo no magnética. - Adhesión superficial con materiales magnéticos

La aplicación o adhesión de materiales magnéticos sobre superficies de aluminio puede proporcionar funciones de atracción o posicionamiento magnético. Se trata de una solución de diseño estructural o funcional más que de un cambio en las propiedades magnéticas intrínsecas del aluminio. - Contaminación por impurezas (indeseable)

Durante el reciclado o la fusión, el aluminio contaminado con impurezas ferromagnéticas puede ser atraído por los imanes. Esto se considera un problema de calidad del material y debe evitarse en la producción industrial.

Metales no magnéticos y breves descripciones

Los metales no magnéticos son materiales que no son atraídos por los imanes y no provocan interferencias magnéticas efectivas en condiciones normales. Son especialmente importantes en la fabricación de precisión, la electrónica y las aplicaciones médicas.

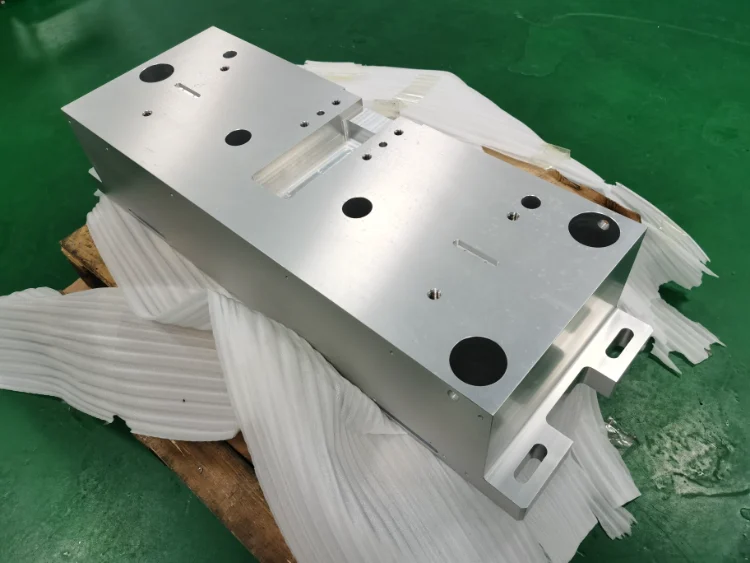

- Aluminio (Al) - paramagnético: Respuesta magnética extremadamente débil, muy utilizada para piezas estructurales, carcasas y componentes mecanizados por CNC.

- Magnesio (Mg) - paramagnético: Ligero y no magnético, se utiliza habitualmente en estructuras ligeras y componentes electrónicos.

- Titanio (Ti) - paramagnético: Alta resistencia y no magnético, ampliamente utilizado en dispositivos aeroespaciales y médicos.

- Platino (Pt) - paramagnético: Respuesta magnética extremadamente débil, utilizada principalmente en procesos químicos e instrumentos de gama alta.

- Cobre (Cu): Típico metal no magnético con excelente conductividad eléctrica, muy utilizado en componentes eléctricos y electrónicos.

- Zinc (Zn): No magnético, comúnmente utilizado para revestimientos resistentes a la corrosión y piezas estructurales.

- Estaño (Sn): No magnético, utilizado principalmente para soldadura, revestimientos y materiales de envasado.

- Plomo (Pb): No magnético, utilizado para blindaje y aplicaciones industriales especiales.

- Oro (Au) y plata (Ag): No magnético y químicamente estable, muy utilizado en conexiones electrónicas y aplicaciones decorativas.

Principales ámbitos de aplicación y componentes del aluminio

Debido a su ligereza, elevada relación resistencia/peso, resistencia a la corrosión y propiedades amagnéticasEl aluminio se considera un material de ingeniería de uso general y se utiliza ampliamente en industrias que requieren reducción de peso, estabilidad y una calidad de procesamiento constante.

En aeroespacial y transporte, el aluminio se utiliza para componentes estructurales, marcos de soporte, carcasas, conectores y paneles funcionales, lo que reduce significativamente el peso total al tiempo que mantiene la resistencia. En el industria del automóvil, el aluminio se aplica ampliamente a paneles de carrocería, soportes, carcasas, componentes de disipación térmica y piezas estructurales de vehículos eléctricos para mejorar la ligereza y la eficiencia energética.

En el industria electrónica y eléctricaEl aluminio, debido a su naturaleza no magnética y a su buena conductividad térmica, se utiliza habitualmente para carcasas de equipos, disipadores de calor, soportes y estructuras de blindaje. En equipos médicos y de precisión, el aluminio se utiliza a menudo para piezas estructurales y de montaje en entornos magnéticamente sensibles para evitar interferencias magnéticas.

En equipos de construcción e industrialesLos perfiles de aluminio se utilizan ampliamente en sistemas de ventanas, muros cortina, marcos industriales y estructuras de equipos de automatización. En Mecanizado CNC y fabricación en generalEl aluminio se procesa habitualmente en componentes de precisión como carcasas, paneles, conectores, espaciadores, soportes funcionales y piezas estructurales personalizadas, equilibrando la eficiencia del mecanizado, la estabilidad dimensional y el control de costes.

Métodos de transformación compatibles con el aluminio

El aluminio ofrece una excelente adaptabilidad de fabricación y admite diversos métodos de procesamiento:

- Mecanizado CNC: Adecuado para fresado, girandoSu propiedad no magnética ayuda a reducir la adherencia de virutas. Su propiedad no magnética ayuda a reducir la adherencia de virutas.

- Extrusión: Permite la producción de perfiles de sección transversal compleja con gran consistencia dimensional, muy utilizados en la construcción y en entramados industriales.

- Fundición y moldeado a presión: Adecuado para estructuras complejas y producción a gran escala, comúnmente utilizado para carcasas de automóviles y equipos.

- Laminación y transformación de chapa: Se utiliza para producir planchas, tiras y láminas, seguidas de operaciones de plegado y estampado.

Opciones de tratamiento superficial disponibles para el aluminio

El aluminio admite una amplia gama de tratamientos superficiales para mejorar la funcionalidad y el aspecto:

- Anodizado / anodizado duro: Mejora la resistencia a la corrosión, la resistencia al desgaste y la consistencia del aspecto.

- Recubrimiento en polvo y pintura: Mejora las prestaciones de protección, se utiliza habitualmente para cerramientos arquitectónicos y de equipos.

- Galvanoplastia y tratamientos químicos: Se aplica para cumplir requisitos funcionales específicos.

- Chorro de arena, cepillado y pulido: Mejoran la textura de la superficie o sirven como pasos previos al tratamiento.

Conclusión: ¿Es el aluminio un metal magnético?

El aluminio no es un metal magnético, sino el típico metal no magnético.

No puede magnetizarse permanentemente, y cualquier "comportamiento magnético" percibido es el resultado de efectos electromagnéticos, estructuras compuestas o impurezas. Esta naturaleza no magnética, combinada con sus propiedades de ligereza, resistencia a la corrosión y excelente maquinabilidad, hacen del aluminio un material insustituible en la industria moderna.

Si desea conocer más detalles u obtener un precio de mecanizado de aluminio, puede contacta con nosotros más tarde.

FAQ de metales magnéticos

¿Por qué se considera que el aluminio es un metal no magnético?

El aluminio se considera un metal no magnético porque su estructura atómica no permite la formación de dominios magnéticos estables. Aunque técnicamente el aluminio es paramagnético, su respuesta magnética es extremadamente débil y no tiene ningún efecto práctico en aplicaciones industriales o cotidianas.

¿Puede el aluminio volverse magnético en determinadas condiciones?

El aluminio puro no puede llegar a ser verdaderamente magnético. Sin embargo, el aluminio puede mostrar un comportamiento magnético débil si contiene impurezas magnéticas (como el hierro) o si se adhieren o recubren materiales magnéticos sobre su superficie. En estos casos, el magnetismo procede del material magnético, no del propio aluminio.

¿Por qué el aluminio reacciona a veces a los imanes fuertes?

El aluminio puede parecer que reacciona a imanes fuertes debido a efectos de las corrientes parásitas. Cuando el aluminio se mueve en un campo magnético intenso, se inducen corrientes eléctricas que crean fuerzas electromagnéticas opuestas. Esto no es magnetismo y no convierte al aluminio en un metal magnético.

¿Es magnético el aluminio fundido?

El aluminio fundido no es magnético. Al igual que el aluminio forjado, las aleaciones de aluminio fundido son metales no magnéticos. Si una pieza de aluminio fundido parece magnética, suele deberse a contaminación por hierro, insertos de acero incrustados o residuos superficiales, no a que el aluminio en sí sea magnético.