CNC machining FR4

CNC machining FR4 is widely used for manufacturing high-strength, electrically insulated components for electronics, power systems, and industrial equipment. FR4 is a glass-fiber-reinforced epoxy laminate that combines excellent mechanical strength, flame resistance, and dimensional stability,

What Is FR4 Material in CNC Machining

FR4 is a composite laminate of woven fiberglass and epoxy resin. In cnc machining fr4, it is widely valued for its structural stability, electrical insulation, and resistance to heat and chemicals.Due to its abrasive glass fibers, it requires specialized tooling and controlled parameters. When machined correctly, it produces precise and durable components for demanding electrical and mechanical applications.

Price: 5-80 USD/PCs(Depending on the size and complexity.)

Tolerance: 0.03 mm~0.1 mm

MOQ: Prototype to mass production

Key Properties of FR4 for CNC Machining

Excellent electrical insulation performance

High mechanical strength-to-weight ratio

Flame-retardant (UL94 V-0 grade)

Good thermal resistance and dimensional stability

Strong resistance to moisture and chemicals

These properties make cnc machining fr4 especially suitable for precision industrial and electronic applications.

CNC Machining FR4 Capabilities

Our cnc machining fr4 services support both prototyping and production with consistent quality.

Machining Processes for FR4

CNC milling FR4 for profiles, slots, and pockets

CNC turning FR4 for cylindrical insulation components

CNC grinding FR4 for flatness and thickness control

Precision drilling and routing

Each process is optimized to minimize delamination and fiber pull-out during cnc machining fr4 operations.

Machining Accuracy and Tolerances

Typical cnc machining fr4 tolerances include:

Standard tolerance: ±0.10 mm

High-precision machining: up to ±0.05 mm

Thickness and flatness tightly controlled for insulation applications

Tolerance results depend on part geometry, thickness, and machining process selection.

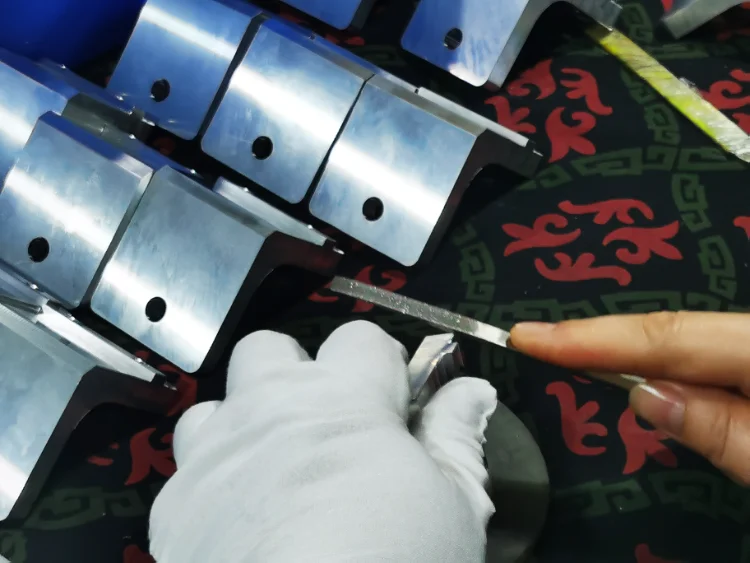

Optional Surface Finishing for CNC Machining FR4

Surface finishing enhances edge quality, safety, and functional performance after cnc machining fr4.

Common Surface Finishing Options

Edge deburring and chamfering

Surface sanding for smoothness

Precision grinding for flat insulation boards

Cleaning and dust-free treatment

- Insulation Coating

- Protective Sealing

Although FR4 is not plated or anodized like metals, proper finishing in cnc machining fr4 improves assembly accuracy and handling safety.

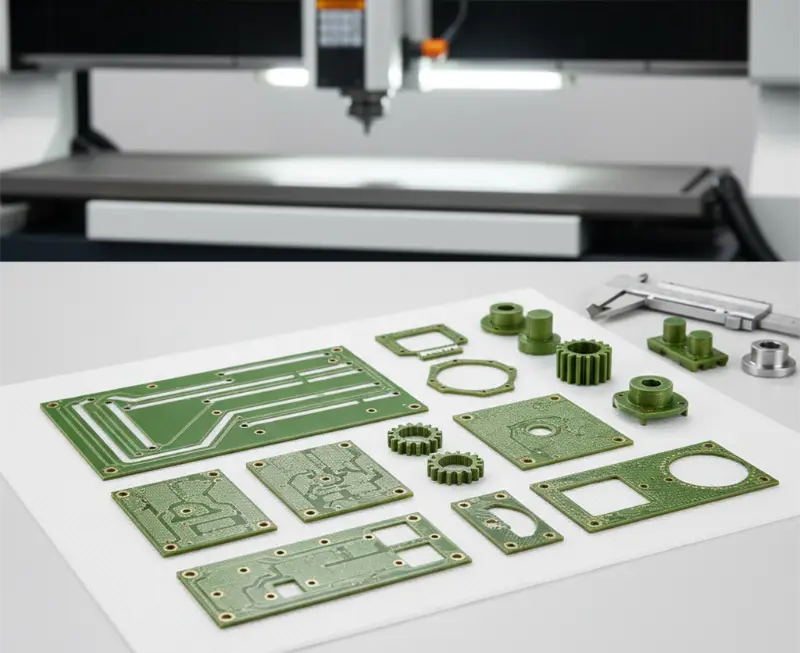

Common CNC Machined FR4 Parts

CNC machining fr4 is commonly used to produce:

Electrical insulation plates

PCB support and mounting panels

Insulating spacers, washers, and bushings

Transformer insulation components

Structural panels for electronic enclosures

These fr4 cnc parts are widely used where mechanical strength and insulation are both required.

Applications of CNC Machining FR4

Industries that rely on cnc machining fr4 include:

Electronics and PCB manufacturing

Electrical power and distribution systems

Industrial automation equipment

Renewable energy systems

High-voltage insulation assemblies

The versatility of cnc machining fr4 allows components to meet both safety and performance requirements.

Challenges in CNC Machining FR4

Due to fiberglass reinforcement, cnc machining fr4 presents unique challenges:

Accelerated tool wear

Dust and fiber particle control

Risk of delamination if parameters are incorrect

Surface edge quality management

Professional cnc machining fr4 requires specialized tooling, controlled feeds, and strict process monitoring.

How We Ensure High-Quality CNC Machining FR4

To ensure consistent results, our cnc machining fr4 process includes:

Abrasion-resistant cutting tools

Optimized milling and grinding parameters

Controlled dust extraction systems

In-process inspection and final quality checks

This approach ensures dimensional accuracy, clean edges, and reliable performance in every fr4 cnc machining project.

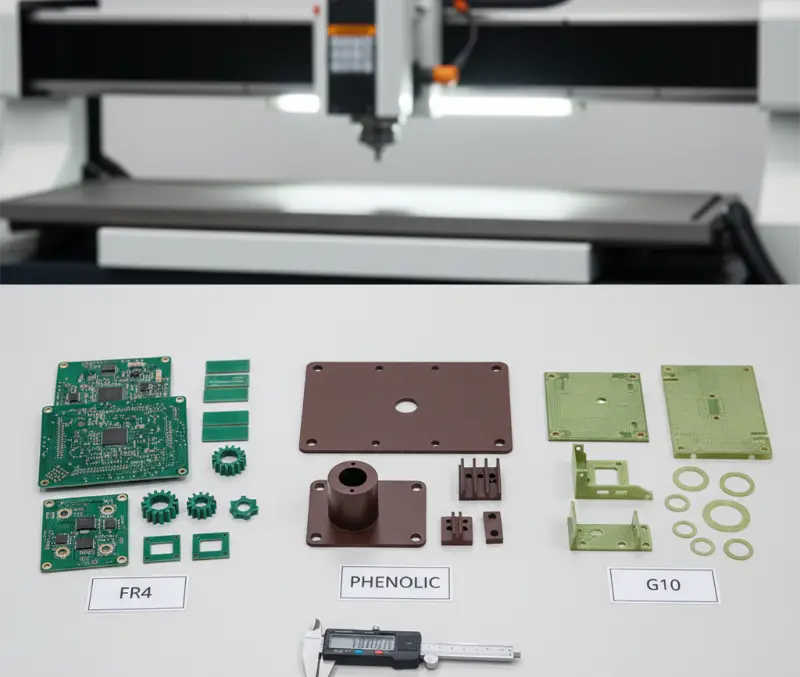

CNC Machining FR4 vs Other Insulation Materials

FR4 vs G10: Similar composition, FR4 offers flame-retardant properties

FR4 vs Phenolic: FR4 provides higher mechanical strength and stability

FR4 vs Engineering plastics: FR4 excels in insulation and heat resistance

These advantages make cnc machining fr4 the preferred choice for critical insulation components.

Why Choose Us as CNC Machining FR4 manufacturer

Full in-house CNC milling FR4 and CNC turning FR4 capability

Support for prototypes and production volumes

Stable quality control and inspection standards

Faster lead time and responsive engineering support

We specialize in precision cnc machining fr4 parts tailored to demanding industrial requirements.

FAQs About CNC Machining FR4

Is FR4 suitable for precision CNC machining?

Yes. With proper tooling and parameters, cnc machining fr4 achieves stable tolerances and clean edges.

Does cnc machining fr4 cause excessive tool wear?

FR4 is abrasive, but optimized tools significantly reduce wear during cnc machining fr4.

Can FR4 be machined for electrical insulation parts?

Absolutely. cnc machining fr4 is commonly used for high-voltage and electronic insulation components.