Understanding 5 axis CNC machining cost is essential for manufacturers and engineers sourcing complex precision parts. Compared with traditional machining, five-axis CNC delivers superior accuracy and flexibility—but it also introduces different cost drivers. This guide explains how 5 axis CNC machining cost is formed, what affects pricing, and how to control total manufacturing expenses.

What Defines 5 Axis CNC Machining Cost?

5 axis CNC machining cost reflects more than just machine time. It represents the combined expense of advanced equipment, skilled programming, tooling, materials, inspection, and risk management.

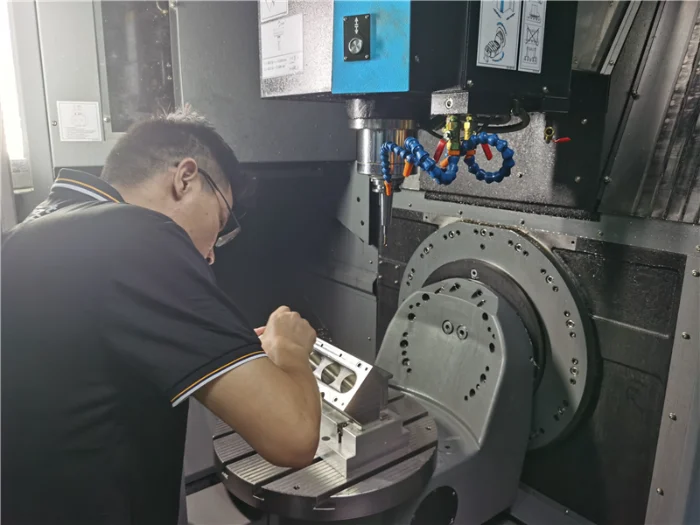

Unlike three-axis machining, five-axis machining allows simultaneous movement along five axes, enabling complex geometry machining in fewer setups. While this reduces rework and improves quality, it also increases hourly machine rates, which directly affects 5 axis CNC machining cost.

5 Axis CNC Machining Capabilities and Cost Impact

The capabilities of five-axis machines significantly influence 5 axis CNC machining cost.

Capability-Driven Cost Factors

- One-setup machining of complex parts

- Multi-angle cutting without refixturing

- Improved surface finish on contoured features

- Tighter achievable tolerances

These capabilities often reduce downstream costs such as secondary operations and manual finishing, partially offsetting higher machine rates.

Material Selection and Its Effect on 5 Axis CNC Machining Cost

Material choice is one of the most influential factors in 5 axis CNC machining cost.

Common Machining Materials

- Aluminum alloys (6061, 7075) – lower cost, high efficiency

- Stainless steel – moderate to high cost

- Titanium and superalloys – high cost

- Engineering plastics – variable cost depending on stability

Harder materials increase tool wear, cycle time, and programming complexity, all of which raise 5 axis CNC machining cost.

Operating Guidelines That Influence Machining Cost

Efficient operation directly controls 5 axis CNC machining cost.

Cost-Optimized Operating Practices

- Use five-axis machining only where geometry requires it

- Reduce tool length to minimize vibration

- Optimize tool paths to maintain constant chip load

- Combine roughing on three-axis with five-axis finishing

Experienced manufacturers balance capability and efficiency to avoid unnecessary cost escalation.

Machining Difficulties and Cost Control Solutions

Advanced machining introduces challenges that can inflate 5 axis CNC machining cost if not managed properly.

Common Difficulties

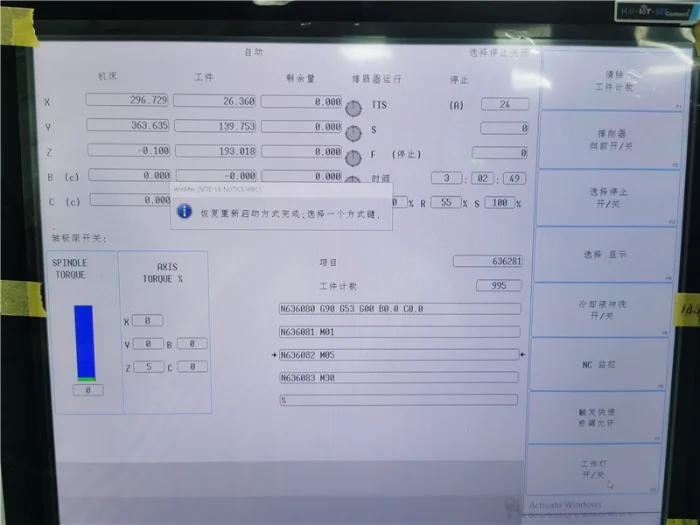

- Complex programming and simulation time

- Collision risk

- Tool deflection during deep machining

- Thermal distortion in long cycles

Cost-Saving Solutions

- Advanced CAM simulation

- Proven post-processors

- Rigid tooling systems

- In-process probing and monitoring

Addressing these issues early prevents scrap and rework, stabilizing overall cost.

Typical Applications and Parts Using 5 Axis CNC Machining

Certain components justify higher 5 axis CNC machining cost due to functional requirements.

Common Applications

- Aerospace structural components

- Impellers and turbine blades

- Medical implants and surgical tools

- Automotive performance parts

- Complex industrial housings

In these applications, five-axis machining reduces total production cost by eliminating multiple setups and manual corrections.

5 Axis CNC Machining Cost Range (Reference)

While pricing varies, typical 5 axis CNC machining cost ranges can be estimated.

General Cost Ranges

- Prototype parts: USD 80–150 per hour

- Low-volume production: USD 70–120 per hour

- High-complexity aerospace parts: Higher due to inspection and documentation

Actual part cost depends on cycle time, material, tolerance, and finishing requirements.

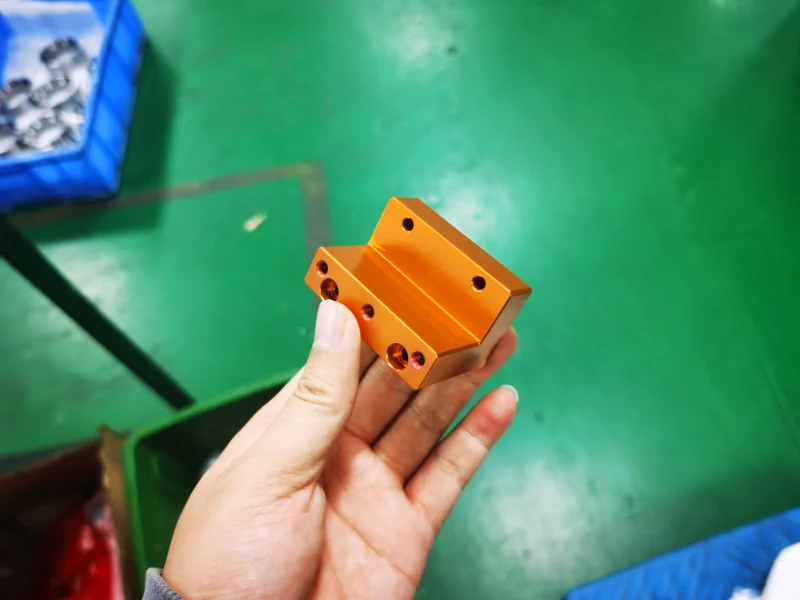

How Surface Finishing Affects 5 Axis CNC Machining Cost

Surface finishing has a direct impact on CNC machining cost, both during machining and post-processing.

Common Surface Treatments

- Anodizing (Type II / Type III)

- Electropolishing

- Passivation

- Bead blasting

- Plating

Finishes with tight thickness control require adjusted machining allowances, additional inspection, and sometimes rework—raising overall cost.

Comparing 5 Axis CNC Machining Cost with 3 Axis and 4 Axis

Understanding relative cost helps with process selection.

| Aspect | 3 Axis | 4 Axis | 5 Axis |

|---|---|---|---|

| Machine Hour Rate | Low | Medium | High |

| Setup Count | High | Medium | Low |

| Accuracy | Standard | Improved | Highest |

| Overall Cost for Complex Parts | High | Medium | Optimized |

For complex geometry, five-axis machining often results in a lower total manufacturing cost despite higher hourly rates.

Cost Optimization Through Process Integration

A professional CNC supplier reduces 5 axis CNC machining cost through process integration.

- Three-axis machining for roughing or Remove excess material after 5 axis machining

- Five-axis machining for precision finishing

- EDM for sharp internal features

- Automated inspection

This hybrid strategy maximizes efficiency and minimizes unnecessary five-axis machine time.

Why Choose Weldo Machining for Cost-Effective 5 Axis CNC Machining

Weldo Machining delivers competitive 5 axis CNC machining cost by combining advanced equipment, experienced engineers, and optimized production workflows. We analyze part geometry, material, tolerance, and finishing requirements to recommend the most cost-effective machining strategy.

Whether you need prototypes or production components, Weldo Machining provides transparent pricing, stable quality, and reliable lead times. Contact us today to receive a detailed cost evaluation and quotation.