Choosing the right 6061-T6 CNC machining manufacturer is essential for producing strong, stable, and cost-effective aluminum components. Because 6061-T6 aluminum offers excellent machinability, durability, and corrosion resistance, it is widely used in aerospace parts, electronic housings, brackets, jigs, and high-precision mechanical structures. Understanding the material’s advantages, machining behavior, and application needs helps buyers select the best machining partner.

Pros and Cons of 6061-T6 Aluminum for CNC Machining

Advantages

- Excellent machinability

Cuts cleanly with carbide tools and supports high-speed milling and turning. - Strong and lightweight

Ideal for structural components that must remain rigid without adding weight. - Corrosion resistant

Works well for outdoor or marine environments, especially when anodized. - Cost-effective

Less expensive than aerospace-grade materials like 7075-T6. - Good weldability

Supports post-machining welding or structural assembly. - Stable T6 temper

Heat treatment ensures predictable hardness and dimensional consistency.

Disadvantages

- Not as strong as 7075

For extreme load-bearing applications, 7075 may be a better choice. - Moderate fatigue resistance

Not ideal for highly repetitive stress environments. - Susceptible to slight burrs

Requires optimized toolpaths and deburring for clean edges. - Can deform if thin-walled

Thin areas need careful fixturing to prevent vibration or warping.

These pros and cons help customers decide whether 6061-T6 is suitable for their CNC aluminum parts.

Why 6061-T6 Is Ideal for CNC Machining

6061-T6 remains one of the most commonly used aluminum alloys due to its strong balance of performance and machinability.

Key Material Properties

- High strength-to-weight ratio

- Excellent corrosion resistance

- Smooth cutting behavior

- Good dimensional stability

- Suitable for polishing, bead blasting, and anodizing

A professional 6061-T6 CNC machining manufacturer can meet strict tolerance requirements and achieve a clean surface finish.

Machining Behavior of 6061-T6 Aluminum

Cutting Speeds and Feeds

- Spindle speeds: 8,000–18,000 rpm

- Feed rate: 0.08–0.25 mm/tooth

- Depth of cut: aggressive for roughing, shallow for finishing

Best Tooling

- 2-flute or 3-flute carbide end mills

- Polished aluminum-specific tools

- Sharp geometry for burr control

Machining Challenges

- Slight burr formation

- Heat accumulation in deep pockets

- Thin walls require support

An experienced 6061-T6 CNC machining manufacturer uses adaptive toolpaths and rigid fixturing to solve these issues.

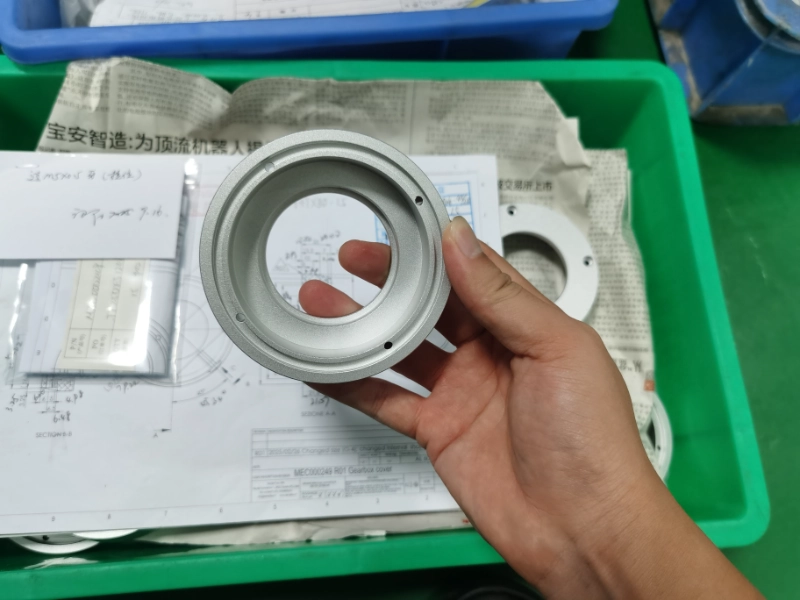

Common Applications of 6061-T6 CNC Parts

Automotive & Motorsport

- Housings, brackets, mounts

- Lightweight structural components

Aerospace & UAV Components

- Connectors

- Precision linkages

- Airframe brackets

Electronics

- CNC-milled housings

- Heat sinks

- Frames and panels

Industrial Machinery

- Fixtures

- Machine bases

- Automation parts

Surface Finishing Options

Standard Finishes

- Type II anodizing (cosmetic & corrosion resistant)

- Type III hard anodizing (industrial wear resistance)

- Sandblasting / bead blasting

- Powder coating

- Brushing & polishing

Finishing selection depends on function, durability, and design expectations.

Reducing Costs With a 6061-T6 CNC Machining Manufacturer

Practical Cost-Reduction Tips

- Avoid unnecessary tight tolerances

- Choose standard stock thicknesses

- Design uniform wall thicknesses

- Specify only required surface finishes

- Use batch production to reduce setup time

A qualified 6061-T6 CNC machining manufacturer can reduce total machining expenses by optimizing toolpaths and material usage.

Conclusion

A reliable 6061-T6 CNC machining manufacturer delivers strong, accurate, and cost-efficient aluminum components suitable for aerospace, automotive, electronics, and industrial applications. By understanding 6061-T6’s advantages, limitations, and finishing requirements, buyers can make better engineering and sourcing decisions.

For expert machining advice, engineering support, or fast quotations, contact Weldo Machining for professional 6061-T6 aluminum CNC solutions tailored to your project.

FAQ of 6061-t6 cnc machining manufacturer

Why is 6061-T6 aluminum widely used for CNC machining?

6061-T6 offers excellent machinability, strength, corrosion resistance, and dimensional stability. It supports high-speed milling and turning, making it ideal for structural and precision components.

What tolerance levels can a 6061-T6 CNC machining manufacturer achieve?

Typical tolerances range from ±0.02–0.05 mm, while high-precision parts can reach ±0.01 mm depending on geometry, tooling, and fixturing.

Does 6061-T6 require post-machining surface treatment?

Not always, but anodizing, bead blasting, brushing, and polishing are often used to enhance corrosion resistance, improve wear performance, or achieve a desired cosmetic finish.

Is 6061-T6 suitable for both prototypes and mass production?

Yes. Its machinability and stable mechanical properties make it ideal for both rapid prototypes and large-scale CNC production runs with consistent quality.