Why 6061 and 7075 Are Commonly Compared in CNC Material Selection

The Core Role of Aluminum Alloys in CNC Machining

Aluminum alloys, with advantages such as lightweight characteristics, excellent machinability, balanced mechanical properties, and controllable costs, have become one of the most widely used metal materials in CNC machining. Compared with metals such as steel and copper, aluminum alloys have a density of only about 2.7 g/cm³, achieving significant weight reduction. They also support high-precision milling, turning, boring, slotting, tapping, deep cavity machining, and other complex processes, meeting machining requirements ranging from general components to high-end precision structural parts. Aluminum alloys are widely used in aerospace, industrial equipment, electronic devices, automotive manufacturing, and many other fields.

Reasons Why 6061 and 7075 Have Become Mainstream Choices

Both 6061 and 7075 belong to the aluminum alloy system, but they represent two core directions: “general-purpose balanced type” and “high-strength type,” forming a highly complementary material selection gradient.

6061 features excellent machinability, medium strength, good corrosion resistance, and cost-effectiveness. It can meet more than 80% of general CNC machining application scenarios and is suitable for both mass production and customized manufacturing.

7075, as an aerospace-grade high-strength aluminum alloy, offers mechanical properties far superior to 6061 and serves as a core material for high-strength load-bearing structures in high-end equipment. It fills the performance gap between ordinary aluminum alloys and expensive special alloys. Together, these two alloys cover most CNC machining requirements from general to high-end applications, making them the primary focus of material comparison.

This article compares 6061 and 7075 aluminum alloys in CNC machining from six dimensions: basic understanding, core performance, machining characteristics, application suitability, cost scenarios, and material selection recommendations, balancing technical parameters with practical application implementation.

Basic Understanding of 6061 and 7075 Aluminum Alloys

Overview of 6061 Aluminum Alloy

6061 belongs to the 6000 series aluminum alloys, with magnesium and silicon as the main alloying elements. It is a heat-treatable aluminum alloy. Its core chemical composition includes magnesium (0.8%–1.2%), silicon (0.4%–0.8%), copper (0.15%–0.4%), chromium (0.04%–0.35%), with the remainder being aluminum and trace impurities.

Its core characteristics include excellent machinability, easy cutting and forming, medium strength (tensile strength ≥310 MPa after T6 heat treatment), good corrosion resistance, good weldability, and controllable cost.

Common applications include industrial structural components, electronic equipment housings, general mechanical parts, automotive components, architectural profiles, and non-standard fixtures.

Overview of 7075 Aluminum Alloy

7075 belongs to the 7000 series aluminum alloys, with zinc as the primary alloying element, supplemented by magnesium and copper. It is an ultra-high-strength aluminum alloy widely used in aerospace and is known as “aerospace-grade aluminum alloy.” Its core chemical composition includes zinc (5.1%–6.1%), magnesium (2.1%–2.9%), copper (1.2%–2.0%), chromium (0.18%–0.28%), with the remainder being aluminum and impurities.

Its core characteristics are excellent mechanical properties, strength far exceeding that of 6061 (tensile strength ≥540 MPa after T6 heat treatment), high hardness, and strong load-bearing capacity. However, it has higher machining difficulty, moderate corrosion resistance, and poor weldability. It is commonly used in aerospace structural components, high-end equipment core parts, and high-strength fasteners.

Differences in Material Positioning and Design Philosophy

The material positioning of 6061 is “general-purpose balanced type,” with a design philosophy focused on cost-effectiveness, ease of machining, and multi-scenario adaptability. It does not pursue extreme strength, but instead focuses on structural support, appearance design, and basic load-bearing requirements. Strength deficiencies can be compensated through structural optimization, making it suitable for mass production and cost-sensitive projects.

The material positioning of 7075 is “high-strength specialized type,” with a design philosophy centered on performance priority, load-bearing compliance, and adaptation to extreme working conditions. It targets applications requiring lightweight and high strength, with less emphasis on machining complexity and cost, prioritizing structural reliability and safety. It is suitable for high-end customization, precision load-bearing applications, and harsh environments.

Comparison of Material Composition and Mechanical Properties

Chemical Composition Differences and Their Performance Impact

Role of magnesium, silicon, zinc, and copper:

Magnesium is a strengthening element in aluminum alloys, enhancing strength and toughness. Combined with silicon, it forms Mg₂Si intermetallic compounds, which are the core strengthening phase of 6061. Silicon improves machinability and casting performance and works synergistically with magnesium to optimize mechanical properties.

Zinc is the primary strengthening element in 7075, significantly enhancing strength. Together with magnesium and copper, it forms Zn-Mg-Cu compounds, achieving ultra-high strength. Copper increases strength and hardness but reduces corrosion resistance. The relatively high copper content in 7075 is the key reason for its superior strength but weaker corrosion resistance compared to 6061.

Explanation of alloy system differences: 6061 belongs to the aluminum-magnesium-silicon (Al-Mg-Si) system, strengthened through solid solution strengthening and precipitation strengthening. After heat treatment, it achieves moderate strength while maintaining good corrosion resistance and machinability, with strong system stability. 7075 belongs to the aluminum-zinc-magnesium-copper (Al-Zn-Mg-Cu) system, strengthened through multi-element synergistic precipitation. T6 heat treatment forms high-density strengthening phases, significantly increasing strength. However, the complex composition increases machining difficulty, and the presence of copper and zinc makes it more susceptible to electrochemical corrosion, resulting in poorer weldability and corrosion resistance than 6061.

Comparison of Strength, Hardness, and Load-Bearing Capacity

Tensile strength: 6061-T6 has a tensile strength ≥310 MPa, while 7075-T6 has a tensile strength ≥540 MPa. The tensile strength of 7075 is more than 74% higher than that of 6061, providing a significant high-strength advantage and enabling it to withstand greater tensile loads.

Yield strength: 6061-T6 has a yield strength (0.2% offset) ≥276 MPa, while 7075-T6 has a yield strength ≥480 MPa. The yield strength of 7075 is approximately 1.7 times that of 6061, offering stronger resistance to deformation under static and impact loads and reducing the likelihood of plastic deformation.

Hardness difference: Measured by Brinell hardness (HB), 6061-T6 has a hardness of approximately 95–105 HB, while 7075-T6 has a hardness of approximately 150–160 HB. The hardness of 7075 is more than 50% higher than that of 6061, providing better wear resistance and making it suitable for load-bearing surfaces subject to wear and extrusion.

Ductility, Toughness, and Fatigue Performance

Impact resistance: 6061 has better ductility, with an elongation (50 mm gauge length) ≥12%, and higher impact toughness. It is less prone to brittle fracture under impact and has stronger fault tolerance. Due to its high-strength design, 7075 has lower ductility, with an elongation (50 mm gauge length) ≥8%, and lower impact toughness than 6061. It is more prone to brittle fracture under severe impact, placing higher requirements on machining precision and structural design.

Long-term reliability: 6061 has moderate fatigue strength and good performance stability under cyclic loading, making it suitable for general components subjected to long-term repetitive use. 7075 has higher fatigue strength and can withstand more frequent cyclic loads, but it is sensitive to machining defects such as burrs and cracks. If residual stress exists after CNC machining, stress cracking may occur during long-term use. Post-machining stress-relief heat treatment is required to ensure reliability.

Comparison of CNC Machining Performance and Machining Difficulty

Cutting Performance and Tool Wear

6061 has excellent cutting performance and is considered an easy-to-machine aluminum alloy. During cutting, chips break easily and evacuate smoothly, causing minimal tool wear. It can be machined using standard high-speed steel tools or carbide tools. Cutting parameter ranges are wide, allowing higher cutting speeds and feed rates without special process requirements.

7075 has relatively poor cutting performance. Due to its high hardness and strength, cutting forces are high, chips are tough and difficult to break, and built-up edge formation is common, leading to severe tool wear. High-precision carbide tools (such as tungsten-cobalt or coated tools) are required. Cutting parameters must be optimized by reducing cutting speed and feed rate, and cutting fluid is often necessary for cooling and lubrication. Tool consumption costs are 30%–50% higher than those of 6061.

Machining Stability and Precision Control

Thin-walled parts: 6061 has good toughness and ductility. When machining thin-walled parts (such as housings or brackets with thickness <1 mm), it is less prone to deformation or edge chipping. Standard fixtures can be used, resulting in high machining stability and easy dimensional accuracy control. 7075, while hard, has poor toughness. Thin-walled machining is prone to deformation and edge chipping due to cutting forces. Specialized fixtures (such as soft fixtures or vacuum fixtures) are required to reduce clamping stress, along with optimized tool paths to control deformation. Precision control is significantly more difficult than with 6061.

High-precision parts: 6061 exhibits good dimensional stability after machining, with low residual stress. After simple stress-relief treatment, it can achieve IT7–IT8 accuracy, meeting most high-precision requirements. 7075 is prone to residual stress during machining. If not relieved in time, deformation may occur later, affecting accuracy. Additional stress-relief heat treatment is required after CNC machining to achieve equivalent accuracy, increasing process complexity and cost.

Surface Quality and Machined Appearance

6061 achieves high surface finish after machining and is less prone to tool marks, burrs, or scratches. After simple grinding, chamfering, and polishing, it can achieve excellent appearance, making it suitable for appearance parts. Its surface flatness is good, and subsequent surface treatments (such as anodizing) produce uniform and consistent results.

Due to higher machining difficulty, 7075 is prone to tool marks, built-up edge residue, and rough surfaces. Additional fine grinding and polishing processes are required to improve appearance, making appearance-part machining more complex. Internal material impurities or segregation may affect surface treatment uniformity, requiring strict control of machining processes and raw material quality.

Impact on Machining Efficiency and Manufacturing Cost

6061 offers high machining efficiency, optimized cutting parameters, minimal tool wear, and no need for complex auxiliary processes. Single-part machining time is short, and consumable costs such as tools and cutting fluids are low. Overall machining cost is low, making it suitable for mass production and effective unit cost control.

7075 has low machining efficiency due to slower cutting speeds, smaller feed rates, frequent tool changes, additional stress-relief heat treatment, and fine finishing processes. Single-part machining time is 1.5–2 times that of 6061. Consumable and process costs are high, resulting in overall machining costs 60%–100% higher than 6061. It is suitable only for small-batch, high-precision, high-strength projects.

Corrosion Resistance, Heat Treatment, and Surface Treatment Compatibility

Corrosion Resistance and Environmental Adaptability

6061 has excellent corrosion resistance. Its low copper content and presence of chromium allow it to form a dense oxide film, resisting corrosion from atmosphere, fresh water, and common acidic and alkaline solutions. It is suitable for humid or mildly corrosive environments without additional anti-corrosion treatment.

7075 has moderate corrosion resistance. Its high copper and zinc content makes it susceptible to electrochemical corrosion, rusting easily in humid, salt spray, or acidic and alkaline environments. Surface treatment (such as anodizing or coating) is required to improve corrosion resistance. It is not suitable for direct use in corrosive environments. In marine environments, special anti-corrosion processes are required; otherwise, service life will be significantly reduced.

Comparison of Common Heat Treatment Conditions (T6 / T651)

T6 condition: Applicable to both alloys, consisting of solution treatment and artificial aging, maximizing mechanical properties and being the most common condition for CNC machining. 6061-T6 has a simple, low-cost process, resulting in balanced strength and hardness with low residual stress. 7075-T6 requires strict control of solution temperature and aging time, achieving extremely high strength but leaving higher residual stress, requiring subsequent stress-relief treatment.

T651 condition: Consists of solution treatment, artificial aging, and stretching straightening. It is mainly used for plates and bars to eliminate residual stress and improve dimensional stability. 6061-T651 is suitable for high-precision plate and bar machining, offering good stress relief and minimal deformation. 7075-T651 is the preferred condition for high-end precision parts, effectively reducing residual stress and post-machining deformation risk, but at higher cost than T6.

Surface Treatment Compatibility

Anodizing: 6061 has excellent compatibility. Anodizing produces a uniform, dense, wear-resistant oxide layer with a wide range of color options (natural, black, gold, etc.). The oxide layer has strong adhesion and is not prone to peeling, making it the most common surface treatment. 7075 can also be anodized, but due to complex composition, oxide layer uniformity is slightly poorer, with potential color differences or pinholes. Process parameters must be optimized, making it suitable for high-strength parts without extreme appearance uniformity requirements.

Sandblasting: Both alloys are compatible with sandblasting. 6061 achieves uniform roughness and a soft texture, suitable for appearance parts. 7075 sandblasting can conceal machining marks and surface defects while improving wear resistance, making it suitable for structural and load-bearing parts. Sandblasting pressure must be controlled to avoid surface damage.

Electroplating/coating: 6061 has good compatibility with electroplating and coating, offering strong adhesion and improved corrosion resistance and appearance. 7075 requires special pre-treatment before electroplating (such as oxide removal and activation) to ensure adhesion. Coating compatibility is relatively good, and electrostatic or powder coating can improve corrosion resistance, making it suitable for corrosive environments.

Cost Factors and Typical CNC Application Scenarios

Material Cost and Comprehensive Machining Cost Comparison

Material cost: 6061 has affordable raw material pricing and abundant market supply, with prices of approximately USD 3,000–5,000 per ton. 7075 has higher raw material costs due to complex composition and difficult production processes, priced at approximately USD 7,000–12,000 per ton, 2–4 times that of 6061.

Comprehensive machining cost: Considering material, tooling, processes, and aging costs, 6061 has significantly lower per-part comprehensive cost than 7075. For CNC parts of the same size, 6061 costs approximately USD 20 per part, while 7075 costs approximately USD 20–40 per part. The cost difference mainly comes from raw materials, tool wear, and additional heat treatment processes.

CNC Application Scenarios Suitable for 6061

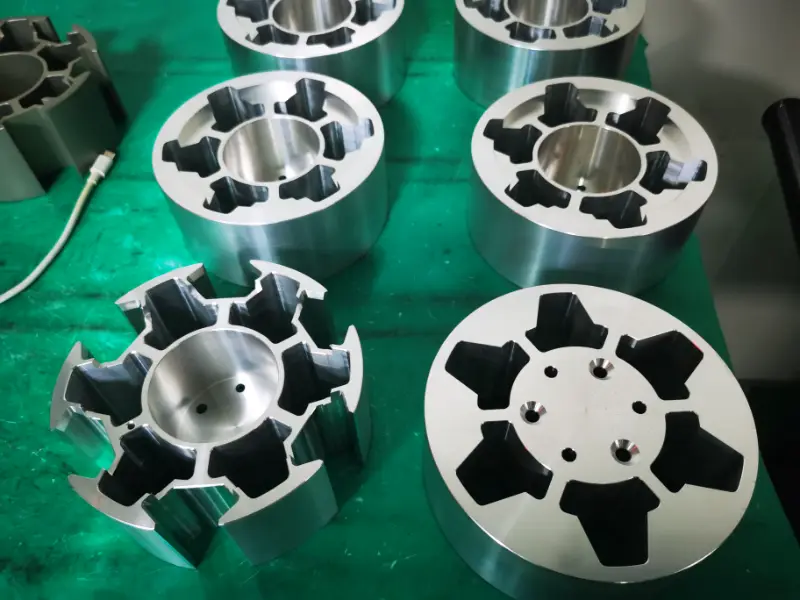

Industrial structural components: Such as machine brackets, equipment frames, fixtures, and conveyor guides, requiring basic load-bearing capacity, machinability, and cost sensitivity. 6061 is well-suited.

Housings and appearance parts: Such as electronic device housings, instrument enclosures, and automotive trim parts, requiring good appearance and surface treatment compatibility. 6061 provides excellent surface quality and anodizing results.

General components: Such as bolts, nuts, valves, fittings, and impellers, requiring mass production, cost control, medium strength, and corrosion resistance. 6061 is the best value-for-money choice.

CNC Application Scenarios Suitable for 7075

Aerospace: Such as aircraft landing gear components, wing structural parts, and satellite brackets, requiring lightweight design, ultra-high strength, and high reliability. 7075 meets extreme operating conditions.

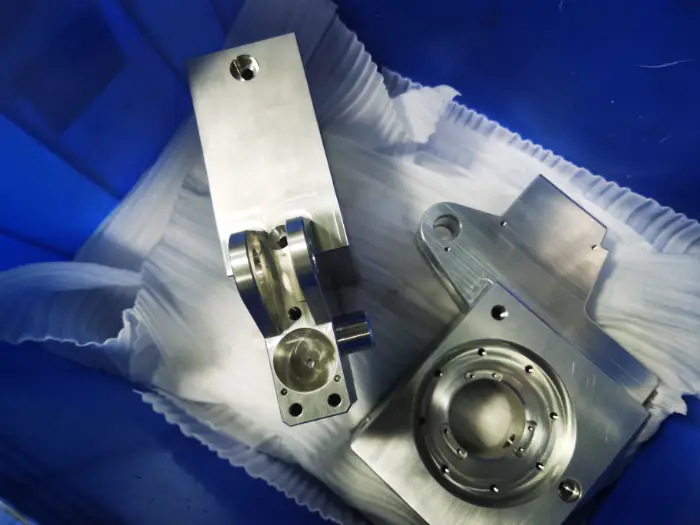

High-strength load-bearing structures: Such as high-end machine tool spindles, precision instrument core supports, drone frames, and high-speed moving components. When 6061 strength is insufficient, 7075 is the optimal choice.

High-end equipment parts: Such as semiconductor equipment precision components, medical device core structural parts, and military equipment components. These require extremely high strength and precision with low cost sensitivity. 7075 ensures performance.

CNC Material Selection Recommendations, Summary, and FAQs

Key Parameter Comparison Table of 6061 and 7075

| Comparison Parameter | 6061 Aluminum Alloy (T6 Condition) | 7075 Aluminum Alloy (T6 Condition) |

|---|---|---|

| Tensile Strength | ≥ 310 MPa | ≥ 540 MPa |

| Yield Strength (0.2% Offset) | ≥ 276 MPa | ≥ 480 MPa |

| Brinell Hardness (HB) | 95–105 HB | 150–160 HB |

| Elongation (50 mm Gauge Length) | ≥ 12% | ≥ 8% |

| Machinability | Excellent, easy to machine, low tool wear | Poor, difficult to machine, high tool wear |

| Corrosion Resistance | Excellent, resistant to atmospheric and freshwater corrosion | Moderate, surface treatment required for corrosion protection |

| Overall Machining Cost | Low, suitable for mass production | High, suitable for small-batch customization |

| Surface Treatment Compatibility | Excellent, anodizing produces uniform results | Good, anodizing requires process optimization to avoid defects |

How to Choose 6061 or 7075 for CNC Projects

From a strength perspective: If parts must withstand large loads, high impact, or require lightweight high strength (such as aerospace or high-end equipment core parts), choose 7075. If only basic load-bearing capacity is required (such as general structural parts or housings), choose 6061.

From a machining difficulty perspective: If parts have complex structures (such as thin walls or precision cavities), require mass production, or need short machining cycles, choose 6061 for its excellent machinability. If parts have simple structures, extremely high precision requirements, and allow high machining costs, choose 7075 with professional machining processes.

From a cost and lead time perspective: If the project is cost-sensitive and has tight delivery schedules, choose 6061 (low material cost, fast machining, no extra processes). If cost sensitivity is low and performance is prioritized, choose 7075 and allow time for heat treatment and fine machining.

From a final application perspective: Choose 6061 for general industrial, electronic, and automotive appearance/structural parts; choose 7075 for aerospace, military, and high-end precision load-bearing parts. For corrosive environments, prioritize 6061. If strength is insufficient, use 7075 with special anti-corrosion treatment.

Plastic Alternatives to 6061 and 7075 Aluminum Alloys in CNC Machining

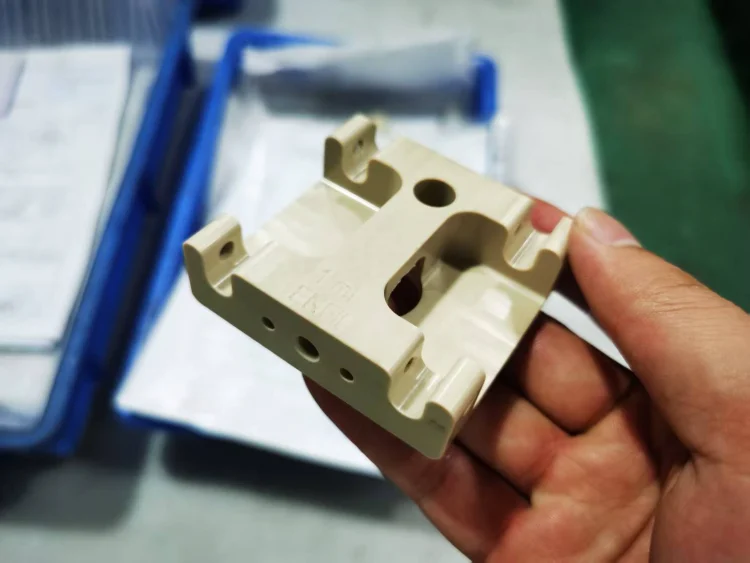

In CNC machining, plastics can serve as alternatives to 6061 or 7075 aluminum alloys under specific conditions. Typical application scenarios include increased lightweight requirements, higher corrosion resistance or electrical insulation needs, no requirement for metal-level high load-bearing strength, or the pursuit of lower machining costs. Material substitution should be based on the performance positioning of the aluminum alloy, distinguishing between general-purpose and high-strength applications.

Plastics as Alternatives to 6061 Aluminum Alloy (General-Purpose Balanced Applications)

6061 aluminum alloy is characterized by medium strength, good machinability, and corrosion resistance. Plastic alternatives should therefore offer good machinability and balanced mechanical performance. Common options include:

- PVC: Low cost, good corrosion resistance, and easy CNC machining. Suitable for pipe fittings and general structural parts without high strength requirements. However, it has poor heat resistance.

- PVDF: Significantly better corrosion resistance than 6061, suitable for chemical processing and ultra-pure water system components, though material cost is relatively high.

- ABS: Excellent machinability and low cost, suitable for electronic housings and general fixtures, but limited in weather and corrosion resistance.

- PC: High impact resistance and wide service temperature range, suitable for transparent or protective structural components, though scratch resistance is limited.

Plastics as Alternatives to 7075 Aluminum Alloy (High-Strength Applications)

7075 is an ultra-high-strength aluminum alloy. Plastics can only replace it in scenarios where strength requirements are moderately reduced but lightweight, corrosion resistance, or insulation performance is emphasized. High-performance engineering plastics are required:

- PEEK: The closest plastic alternative to 7075 in overall performance, offering high strength, high-temperature resistance, and excellent corrosion resistance. Suitable for high-end equipment and aerospace auxiliary structures, but extremely expensive.

- PPS: Good strength and corrosion resistance, suitable for high-temperature structural components, though toughness is relatively low.

- PI: Outstanding high-temperature resistance and excellent electrical insulation, suitable for aerospace and military components in high-temperature zones, but with high cost and machining difficulty.

- CFRP (Carbon Fiber Reinforced Plastics): Exceptional strength-to-weight ratio and lightweight performance, capable of partially replacing 7075 in extreme lightweight structures. However, machining cost and process requirements are very high.

Key Principles for Material Substitution

- Strength Matching Comes First: For high-load-bearing applications, plastics cannot fully replace 7075; carbon-fiber-reinforced materials are the closest alternatives.

- Operating Conditions Are Critical: In corrosive, high-temperature, or electrically insulated environments, plastics offer clear advantages over aluminum alloys.

- Comprehensive Cost Evaluation: Standard plastics can reduce costs, but high-performance plastics are often significantly more expensive than aluminum alloys.

- Acceptance of Performance Trade-Offs: Plastics generally have lower stiffness, thermal conductivity, and wear resistance than aluminum alloys. Structural optimization is required to compensate when substituting.

Conclusion

Overall, 6061 and 7075 aluminum alloys each have their own strengths in CNC machining. 6061, with its good machinability, corrosion resistance, and lower cost, is suitable for most general structural components, aesthetic parts, and mass production scenarios. 7075, on the other hand, with its significantly higher strength and load-bearing capacity, is the ideal choice for aerospace and high-end, high-strength parts, but it also presents greater machining difficulties and higher costs. When selecting materials, it is essential to consider strength requirements, machining difficulty, operating environment, and budget to strike a balance between performance and cost-effectiveness.