As demand for high-strength, aerospace-grade materials increases, many engineers evaluate 7050 aluminum cnc machining cost to understand how this premium alloy performs in structural components and precision parts. Known for its exceptional strength-to-weight ratio and stability, 7050 aluminum requires specialized machining strategies to achieve reliable, high-quality CNC results.

Key Material Properties of 7050 Aluminum

7050 aluminum is widely used in aerospace structures because it combines high mechanical strength, excellent fatigue resistance, and strong corrosion performance. These properties directly influence machinability and the total 7050 aluminum cnc machining cost. To better understand its engineering characteristics, the following data summary highlights the performance values most relevant to CNC machining.

7050 Aluminum – Core Performance Data for CNC Machining

| Property | Typical Value (7050 Aluminum) | Relevance to CNC Machining & Cost |

|---|---|---|

| Density | 2.83 g/cm³ | Lightweight; affects material cost and aerospace applicability |

| Yield Strength | 455–505 MPa | Higher cutting load → increased machining time and tool wear |

| Tensile Strength | 520–590 MPa | Greater resistance → requires optimized tooling and feeds |

| Brinell Hardness | 150–170 HB | Harder surface causes faster tool wear and higher tooling expense |

| Fatigue Strength | 160–180 MPa | Suitable for high-load aerospace parts → demands tight tolerances |

| Elastic Modulus | 71–73 GPa | Minimizes deformation during machining → improves dimensional accuracy |

| Thermal Conductivity | 130–150 W/m·K | Good heat transfer but still requires coolant to avoid hardening |

| Thermal Expansion (CTE) | 23.5–24.0 µm/m·°C | Heat buildup during CNC processing may cause micro-distortion |

| Stress Corrosion Resistance | High (T7451/T7651) | Ensures long-term reliability of machined aerospace components |

Why 7050 Aluminum Is Popular in Aerospace and Defense Components

7050 is widely used in:

- Hydraulic systems

- Wing and fuselage connection plates

- Military-grade brackets and frames

- High-load mechanical couplings

- UAV structures

- Precision machined blocks

Because of its mechanical stability and low density, engineers often select 7050 when both performance and manufacturability must be optimized.

Machinability Characteristics of 7050 Aluminum

Although 7050 aluminum machines better than titanium or stainless steel, it requires careful programming and tool selection to achieve the best results.

Moderate Machinability

7050 is harder than 6061 and 7075, requiring optimized cutting speeds and feeds. Tool wear increases machining time, affecting 7050 aluminum cnc machining cost.

Requires Sharp, Coated Tools

To maintain surface finish and dimensional accuracy, carbide tools with TiAlN/TiCN coatings are often recommended.

Heat Sensitivity During High-Speed Milling

Heat buildup may harden the material surface, especially in deep-pocket machining. Coolant flow and toolpath strategy are essential.

Excellent Surface Finish

When machined correctly, 7050 produces clean, polished surfaces ideal for aerospace assemblies.

CNC Machining Processes Commonly Used for 7050 Aluminum

Several machining processes contribute to high-quality 7050 parts machining.

3-Axis CNC Milling

Suitable for flat surfaces, shallow pockets, and general mechanical components.

5-Axis CNC Machining

Widely applied to complex aerospace geometries such as brackets, housings, and structural connectors.

Using 5-axis capability improves accuracy and reduces fixturing steps, influencing 7050 aluminum cnc machining cost.

CNC Turning

Used for rods, bushings, and cylindrical components requiring high tolerance and surface finish.

Deep Drilling and High-Speed Hole Milling

7050’s toughness demands stable drilling conditions to avoid burrs or tool deflection.

Industries and Applications of 7050 Aluminum CNC Machined Components

7050 aluminum parts machining is important for industries such as:

- Aerospace

- Defense systems

- Motorsport engineering

- Robotics

- High-load mechanical assembly

- Industrial automation

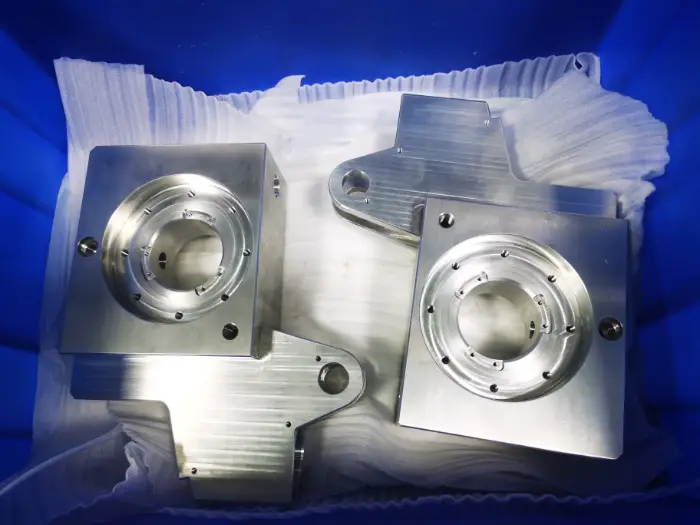

Typical CNC-machined 7050 parts include:

- Landing gear housings

- Suspension brackets

- Chassis plates

- UAV frame connectors

- Precision mounting blocks

- High-stress joint plates

Key Factors Affecting 7050 Aluminum CNC Machining Cost

Understanding 7050 aluminum cnc machining cost requires analyzing multiple production, material, and engineering-related factors.

1. Material Price and Block Size

7050 aluminum is more expensive than 6061, 7050, or 2024, especially in thicker plates. Larger stock sizes significantly influence the base cost.

2. Machining Complexity

Complex aerospace components requiring 5-axis machining or deep pockets increase:

- Programming time

- Toolpath length

- Machining hours

3. Required Tolerances

High-precision aerospace requirements (±0.005–0.02 mm) drastically increase machining time and inspection requirements.

4. Tool Wear and Breakage

7050’s hardness increases tool consumption, which directly impacts machining cost.

5. Heat Treatment or Post-Processing

7050 often requires:

Anodizing or chemical conversion also affects cost.

6. Production Volume

Small batches (1–10 pcs) cost more per unit compared with medium-volume runs (50–500 pcs).

Typical Price Range for 7050 Aluminum CNC Machining

While exact pricing depends on geometry and tolerance, here are common ranges:

| Part Complexity | Typical Cost (per piece) |

|---|---|

| Simple 3-axis components | $30–$80 |

| Medium-complexity brackets | $80–$180 |

| Complex 5-axis aerospace parts | $180–$600+ |

| High-precision military components | $300–$1,200+ |

Custom aerospace machining often involves multi-step inspection, contributing to cost.

How to Reduce 7050 Aluminum CNC Machining Cost

Engineers can optimize design and machining conditions with:

1. Simplified Geometry

Avoid unnecessary pockets or thin walls that increase machining time.

2. Balanced Tolerances

Apply tight tolerances only where functional requirements demand.

3. Smart CNC Strategy

Using a hybrid workflow—roughing on 3-axis machines and finishing on 5-axis centers—minimizes high-cost machining time.

4. Batch Production

Ordering 5–20 pcs at a time significantly reduces per-unit cost.

5. Material Optimization

Optimize stock thickness to reduce waste.

Choosing a Trustworthy 7050 Aluminum Machining Supplier

A reliable supplier should provide:

- CNC equipment capable of 3- to 5-axis machining

- Aerospace-grade inspection systems

- Experience with 7050 and other 7-series alloys

- Stable process control for repeatability

- Support for anodizing and chromate finishing

- Engineering guidance for cost optimization

Selecting an experienced vendor ensures machining quality and predictable total cost.