Reasons for Choosing CNC Machining Services

With the development of computer technology and increasing demands for equipment part precision, requirements for product dimensional accuracy in fields such as aerospace, medical devices, automotive new energy, automotive parts, and consumer electronics have reached the micrometer level.Compared to manual crafting and traditional manual milling and lathe machines, CNC machining services offer higher precision and faster production speeds. Once programmed, machines can automatically process workpieces without human intervention, ensuring accuracy and reducing material waste caused by human errors. Complex engine blades with curved surfaces, which are difficult to machine manually to required dimensions, can be safely and quickly completed using 5-axis CNC machining, ensuring customer delivery deadlines and the normal operation of machinery.The following is the CNC machining service guideline

5 Core Advantages of CNC Machining Services

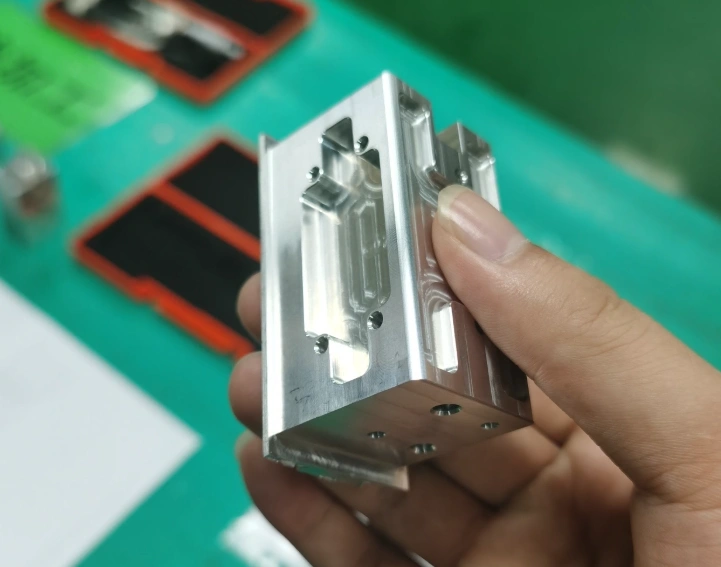

Precision Manufacturing Capability

Engineers set computer programs based on prototype drawings to control tool milling systems, cooling units, and workpiece fixture operations. Utilizing CNC machines equipped with high-rigidity spindles (up to 30,000 RPM) and micrometer-level servo systems, mirror-like polishing effects with surface roughness (Ra ≤ 0.2μm) can be achieved, meeting high-gloss tolerance standards for materials like metal and glass in applications such as optical lenses and semiconductor equipment.

Complex Structure Forming

4/5-axis simultaneous machining technology enables the processing of structures like multi-faced spiral gears and irregular holes that cannot be completed by ordinary milling or turning machines.This reduces tool replacement and clamping times, avoiding multiple positioning errors caused by manual workpiece angle adjustments.

Wide Range of Machinable Materials

From soft plastics (e.g., PEEK) to superhard alloys (e.g., tungsten steel), CNC achieves rapid processing by adjusting cutting parameters (feed rate, spindle speed) and tool selection, meeting high standards while reducing material damage probabilities compared to ordinary lathes.

Intelligent Quality Traceability System

Advanced CNC machines integrate IoT sensors to continuously monitor parameters such as tool wear, spindle temperature, speed, feed rate, and fixtures, automatically generating processing logs.

This ensures each product is traceable to specific work orders and operators, facilitating periodic reviews to enhance engineers’ processing experience.

Rapid Prototyping Verification

Combining preliminary 3D printing and CNC subtractive processing, functional prototypes can be delivered within a minimum of 12 hours from design, effectively saving time costs for new product development.

Mainstream Materials Supported by CNC Machining Services

Material Category | Common Materials | Applications | Key Processing Notes |

Metals | Aluminum 6061-T6, Stainless Steel 304, Titanium TC4 | Aerospace structural parts, Medical implants, Automotive components | Use diamond-coated tools; control cutting heat and feed rate |

Engineering Plastics | Semiconductor fixtures, Food-grade containers, Catheters | Apply coolant to prevent material deformation | |

Composite Materials | Carbon Fiber Reinforced Plastic (CFRP), Fiberglass | Drone bodies, Sporting equipment | |

Superalloys | Chemical valves, Marine engineering equipment | Pre-treat material internal stress to avoid cracking | |

Soft Metals | Purple Copper, Brass | Electrical connectors, Decorative parts | High spindle speed (≥8,000 RPM) to prevent tool adhesion |

Ceramics | Blade coatings, Bioceramics | Use ultrasonic-assisted machining | |

Foam Materials | Aerospace fillers, Packaging materials | Low feed rate (≤500 mm/min) to prevent cracking | |

Rare Metals | Tungsten, Molybdenum | High-temperature furnace components, X-ray targets | Process under inert gas protection |

Elastomers | Silicone, Fluororubber | Seals, Medical catheters | Use cryogenic machining to maintain shape |

Memory Alloys | Heart stents, Smart glasses hinges | Precisely control processing temperature (≤50°C) | |

Powder Metallurgy Parts | Complex gears, Watch movements | Reserve 0.05mm polishing allowance | |

Transparent Materials | Acrylic, PC (Polycarbonate) | Optical lenses, Bulletproof glass | Use single-edged tools to minimize light transmission loss |

Technical Tip:

For titanium alloy machining, adopt high-pressure cooling (≥70 bar) and helical interpolation milling to extend tool life by 300%.

6 Major Industry Applications of CNC Machining Services

Aerospace

Case Study: A U.S. satellite bracket, machined from aluminum alloy using CNC, reduced weight by 40% while increasing stiffness by 25%, passing extreme temperature tests from -196°C to +200°C.

New Energy Vehicles

Core Components: Battery trays (6061 aluminum alloy), motor end covers (316L stainless steel), and charging ports (PBT+GF30 plastic) rely on CNC precision machining to achieve IP67 waterproof ratings.

Medical Devices

Precision Requirements: Orthopedic implants (titanium alloy) in large hospitals require 0.01mm-level precision for seamless bone integration and surface roughness (Ra ≤ 0.1μm) to promote bone cell growth.

Semiconductor Manufacturing

Critical Parts: Durable robotic arms (PEEK material) and lithography machine light shields (superhard aluminum 7075) are processed with tolerances controlled within ±0.005mm.

Robotics Industry

Typical Applications: Balancing lightweight and toughness, many advanced CNC machining enterprises produce specialized joints (harmonic drive wave generators) for collaborative robots and AGV cart navigation brackets.

Consumer Electronics

Innovative Products: Samsung and Huawei’s foldable smartphone hinges (316L stainless steel) and VR headset optical modules (PMMA plastic) achieve micrometer-level assembly precision through CNC, ensuring efficient synergistic use.

WELDO CNC Machining Services: A Trusted Precision Manufacturing Partner

As an ISO 9001:2015 certified enterprise, WELDO offers one-stop CNC machining solutions from prototyping to mass production, significantly saving time costs and eliminating the hassle of multi-factory, multi-process transitions:

- Equipment Strength: 50 Taiwan Jirfine (Brother) 3/4-axis CNC machines, 10 U.S. Hurco and HAAS 5-axis CNC machines, and multiple large/small CNC grinding machines, fast/medium-speed wire cutting machines (totaling 8), and ordinary lathes/milling machines (8). The machining center supports a maximum processing size of 3000mm × 2000mm × 1000mm.

- Material Library: Over 100 common production material samples stored, with special material procurement possible within 12 hours.

- Inspection Capability: Equipped with professional automatic coordinate measuring machines, height gauges, and projectors for 100% full inspection or random manual/machine comparison sampling of processed parts.

- Delivery Lead Times: 1-3 days for ≤10 sample prototypes, 7-10 days for small batches (100-1000 pieces), and 15-20 days for large batches (1000+ pieces).

CNC Machining Services FAQ

Q1: What files do I need to provide to get a quote?

A: Please provide 3D model files (STEP/IGES/SOLIDWORKS format) and 2D engineering drawings (annotated with key dimensions and tolerances).

If no CAD files are available, we offer reverse engineering services (additional fees apply) to design CAD structural drawings and multi-angle flat plans from sketches.

Q2: How do you ensure machining accuracy meets requirements?

A: We implement three-stage quality control:

- Programming Stage: Simulate machining paths using VERICUT software to preemptively identify collision risks.

- First-Article Inspection: Use CMM to measure critical dimensions and generate inspection reports for customer and production manager confirmation.

- Process Monitoring: Real-time data collection on spindle load, tool wear, etc., with automatic machine shutdown in case of abnormalities.

Q3: What is the minimum order quantity (MOQ)?

A: We support orders starting from 1 piece, with unit prices decreasing as quantities increase. For example:

- Aluminum prototype (1 piece): ¥850/piece

- 100-piece batch: ¥420/piece (50% reduction)

- 1000-piece batch: ¥280/piece (67% reduction)

Q4: Can you machine materials harder than HRC50?

A: Yes! We use CBN (Cubic Boron Nitride) tools to machine quenched steel (HRC55-62) and equip high-pressure cooling systems (100 bar) to prevent tool overheating.

Typical case: Machined HRC58 DC53 mold steel for a mold factory, reducing single-piece processing time by 40% compared to ordinary tools.

Q5: How to get a quick quote?

A:1. Online quote: Visit the WELDO site, upload your files, and receive an estimated price within 1 hour (during business hours);

- Email inquiry: send inquirement to cg@weldomachining.com, response within 2 hours;

Take action now and bring your precision designs to life!