In today’s increasingly competitive manufacturing industry, companies must ensure the high precision and durability of their parts while controlling production costs to maintain competitiveness. As a core manufacturing process, price optimization in CNC machining has become a critical issue. This article will explore how to effectively reduce CNC machining price without sacrificing quality from three dimensions: technology, management, and supply chain, providing consumers with practical solutions.

Core Components and Optimization Logic of CNC Machining Price

CNC machining Material price: Full-Chain Control from Selection to Utilization

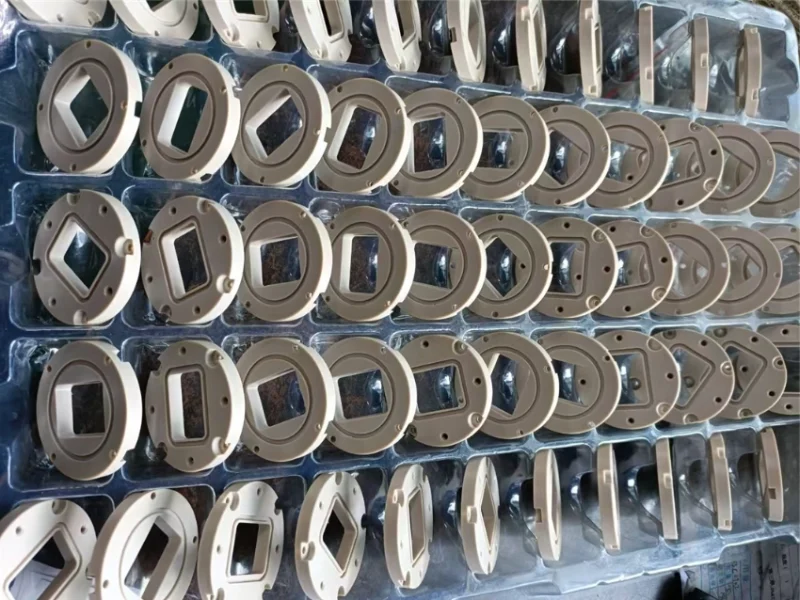

Material price account for 30%-50% of the total CNC machining price and are a key area for optimization. First, customers can choose the most cost-effective material based on the functional requirements of the parts. For example, 6061 aluminum alloy can be used instead of 7075 aluminum alloy for ordinary structural parts, reducing costs by approximately 40%, while optimizing the layout design reduces waste. This ensures the strength requirements of the parts are met and costs are reduced. Second, establishing long-term cooperation agreements with suppliers and reducing unit prices through bulk purchasing.

Machining Process: The Balance Between Efficiency and Precision

Machining processes directly affect working hours and equipment wear and tear. Enterprises can optimize their processes through the following methods:

Process simplification: Combine milling, drilling, and other operations to reduce the number of setups. For example, replacing 3 axis machining with 5 axis machining reduces the time per piece by 30%. If the quantity of work is small and the structure is simple, it can be directly machined on a conventional milling lathe, reducing uptime and lowering production costs and consumption for customers while ensuring dimensional and structural accuracy requirements.

Tool management: Select high-performance, cost-effective tools, such as carbide-coated tools instead of pure tungsten steel tools, extending tool life by 2 times and reducing tool cost per piece by 50%.

Parameter optimization: Adjust spindle speed and feed rate according to material characteristics to avoid excessive cutting and equipment wear.

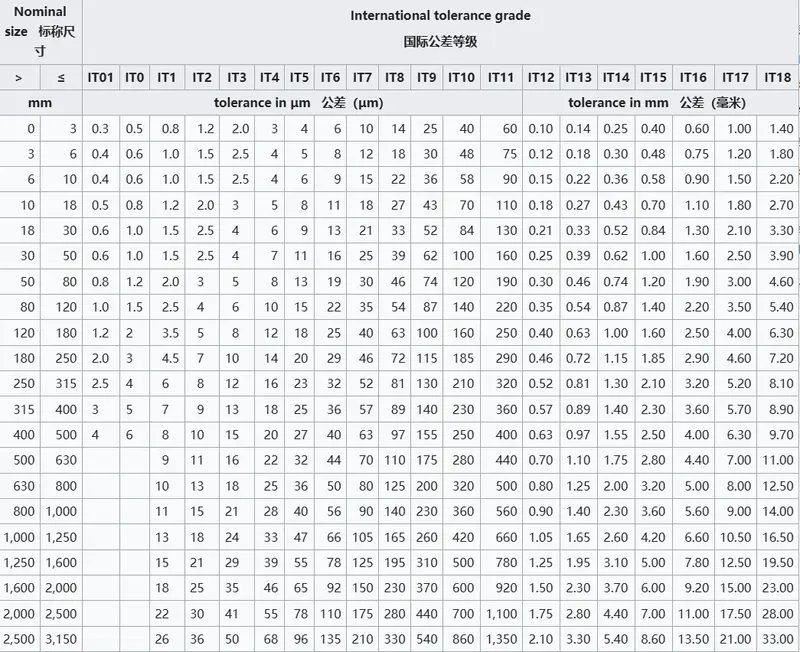

Clearly define precision requirements and avoid over-processing.

Function-oriented precision grading: Based on the actual usage scenario of the part (e.g., structural support, motion fit, sealing, etc.), precision requirements are divided into critical dimensions, secondary dimensions, and non-critical dimensions. For example:

Critical dimensions (e.g., hole-shaft fit): Maintain high precision (IT7-IT8) to ensure normal function.

Secondary dimensions (e.g., appearance surfaces): Can be relaxed to IT9-IT10, with minor imperfections concealed through surface treatment.

Non-critical dimensions (e.g., mounting hole positions): Allow IT11-IT12, compensated for by assembly tolerances.

An auto parts company reduced the machining accuracy of non-mating surfaces from ±0.02mm to ±0.05mm, shortening the single-piece machining time by 20%, reducing tool wear by 15%, and reducing annual price by $120,000.

Flexible selection of processing equipment to match precision requirements:

High-precision scenarios: Using high-speed machining centers or precision milling machines ensures critical dimensional tolerances are ≤ ±0.01mm, suitable for aerospace, medical, and other fields.

Medium-to-low precision scenarios: Employing ordinary CNC milling machines or machining centers, tolerances are relaxed to ±0.05mm, suitable for structural parts, non-mating surfaces, etc., reducing equipment depreciation and labor costs by 40%.

Extremely low precision scenarios: For appearance parts or non-functional surfaces, ordinary milling machines or manual machining can be considered, controlling tolerances within ±0.1mm, further reducing costs.

Equipment and Labor: Long-term returns of intelligent upgrades

Equipment depreciation and labor costs account for 20%-30% of the total CNC machining price. Businesses can reduce costs through the following methods:

Equipment Upgrades: Introducing high-speed machining centers increases cutting speed by 50% and reduces single-piece processing time by 40%.

Personnel Training: Improving operator efficiency and reducing scrap rates through skills certification systems. For example, one company reduced operator programming error rates from 5% to 0.8% through training, reducing annual rework costs by $80,000.

Automation Integration: Adopting robotic loading and unloading systems reduces manual intervention and increases single-shift productivity by 35%.

Supply Chain Collaboration: From Single-Point Optimization to Systemic Cost Reduction

Supplier Integration: Reducing Intermediaries

Establishing direct partnerships with raw material suppliers and tool manufacturers eliminates distributor markups.

Inventory Management: JIT Model Practice

Adopting a Just-In-Time (JIT) production model dynamically adjusts raw material inventory based on orders. Real-time inventory monitoring through the ERP system helps prevent overstocking and stockouts.

Logistics Optimization: Regionalized Layout Establish

Processing centers in market areas close to customers to shorten transportation distances and delivery cycles.

Quality Assurance System: Reduce cnc machining price Without Quality Compromise

Process Control: Application of SPC Statistical Technology

By collecting processing data in real time (such as spindle temperature and vibration frequency), SPC (Statistical Process Control) charts are used to monitor quality fluctuations. Through the SPC early warning system, the defect rate was reduced from 0.5% to 0.1%, resulting in a reduction of $150,000 in annual quality losses.

Inspection Technology: Popularization of Non-Destructive Testing

Using non-destructive testing technologies such as X-rays and ultrasound to replace traditional sampling inspections, 100% full inspection is achieved. An aerospace parts company increased its internal defect detection rate to 99.9% through non-destructive testing, avoiding huge compensation claims due to customer complaints.

Standardized Operations: Strict Implementation of SOPs

Standardized operating procedures (SOPs) are established, clearly defining the parameter range and operating specifications for each process. An automotive mold company improved operational consistency by 60% and extended equipment downtime to 800 hours through SOP training.

WELDO‘s Solutions: Dual Guarantee of cnc machining price and quality

As a professional CNC machining service provider, WELDO helps clients reduce costs and increase efficiency through the following methods:

Intelligent Quotation System: Quickly generates transparent quotations based on AI algorithms, covering the entire cost chain, including materials, processes, and logistics.

Process Optimization Services: Provides DFM (Manufacturability Analysis), suggesting alternative materials and simplified processes, resulting in an average cost reduction of 15%-25%.

Quality Traceability System: Full traceability from raw material batches to finished product testing data, supporting ISO 9001, IATF 16949, and other certification requirements.

Take Action Now: Visit the WELDO website homepage and contact our dedicated quotation customer service representative to obtain your customized CNC machining quotation and price reduction solution!

Article Summary

Reducing CNC machining price does not come at the expense of quality, but is achieved through systematic improvements in material selection, process efficiency, supply chain collaboration, and quality assurance systems. Enterprises need to shift from single-point cost reduction to overall optimization, combining intelligent tools and professional services to gain a competitive edge.

FAQ of reduce cnc machining price

Will reducing material costs affect part strength?

No. Through material performance testing and finite element analysis (FEA), equivalent alternative materials can be selected. For example, the strength difference between 6061 aluminum alloy and 7075 aluminum alloy in ordinary structural parts is less than 10%, but the cost is lower.

Will process simplification lead to a decrease in machining accuracy?

No. Five-axis simultaneous machining can complete the machining of complex curved surfaces in one operation, with tolerance control reaching ±0.005mm, which is better than the ±0.01mm of traditional three-axis machining.

Will ordinary cnc lathes reduce the machining standards and accuracy of products?

In the machining of single-piece or small-batch non-standard parts, ordinary cnc machines, with their flexibility, can achieve similar accuracy to CNC (e.g., hole spacing error ≤0.03mm) with skilled operation, and will not necessarily reduce machining standards.

After strictly controlling equipment status, operating procedures, and process design, ordinary cnc milling/turning machines can achieve qualified machining of products with an accuracy of IT11 level (±0.05mm) or lower.

How to ensure the material quality after supplier integration?

Quality stability can be achieved through supplier audits (such as ISO 9001 certification), incoming quality control (IQC), and batch management. After implementation, one company saw its material defect rate decrease from 0.8% to 0.2%.

Does WELDO’s service support small batch orders?

Yes. WELDO provides flexible services from single-piece sampling to mass production, with a minimum order quantity (MOQ) of 1 piece. Furthermore, its quick mold change technology reduces time losses for small batch orders by 30%.