ABS Material Characteristics and CNC Machining Compatibility

ABS (acrylonitrile-butadiene-styrene copolymer), a commonly used engineering plastic in CNC machining, has a density of 1.04-1.06 g/cm³, a melting temperature of 200-250℃, and combines structural strength with lightweight advantages. It also exhibits excellent dimensional stability, making it an ideal base material for CNC machined ABS parts.

Mechanical Properties and Processing Advantages

CNC machined ABS parts exhibit excellent impact strength (notched impact strength 20-40 kJ/m²) and rigidity. They have good chip-breaking performance during cutting, avoiding the long chips of polyethylene and the severe tool wear problems of polyoxymethylene, making them particularly suitable for manufacturing precision parts subjected to impact loads.

Impact of Material Modification on Machining

The impact of material modification on CNC machined ABS parts needs attention: Glass fiber reinforced ABS increases strength but exacerbates tool wear; flame-retardant ABS containing halogenated flame retardants may corrode equipment, requiring timely cleaning of debris after machining.

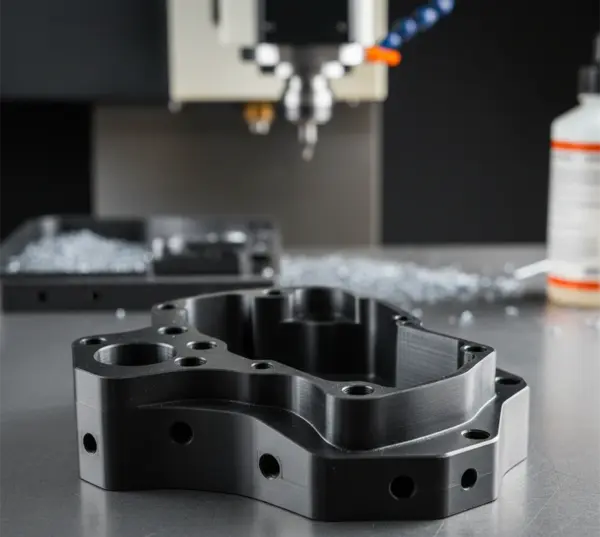

Production Case: Precision Machining of the Joystick Unit Main Housing (ABS)

This part project, the main housing of the Joystick unit, has a production quantity of 500 units. The material used is an ABS + PC blend, with a matte black surface finish.

In terms of machining, a combination of five-axis and three-axis CNC machining technologies was employed. First, 5-axis CNC machining was used to mill and drill holes on the bottom and outer perimeter of the housing, as well as to round the edges to improve the feel of the housing. The advantage of 5-axis machining is that it can machine parts from multiple angles, and it is particularly suitable for handling complex curved surfaces on the edges of ABS housings, ensuring the shape accuracy and hole position accuracy of the bottom and outer parts.

After completing the 5 axis machining, a 3-axis CNC machine tool was used to precision mill the internal structure of the housing. The reason for performing five-axis machining first and then 3-axis machining is based on considerations of optimizing the machining process and cost. Five-axis machining is time-consuming when machining complex parts, while 3-axis machining is more efficient when handling relatively regular internal structures. This processing sequence effectively reduces the time spent on 5-axis machining, saving customers processing costs. Simultaneously, the increased number of 3-axis machines further improves delivery speed.

This case fully demonstrates the application strategy of CNC machining technology in the manufacturing of precision ABS parts. By rationally combining 5-axis and 3-axis machining processes, both cost and efficiency are optimized while ensuring part quality.

CNC Machining Process Optimization for ABS Parts

The core of achieving high-quality CNC machined ABS parts lies in precise control of process parameters. High-speed steel or carbide tools are recommended; carbide tools are particularly suitable for batch machining or reinforced ABS machining.

Cutting Parameter Optimization

CNC machined ABS part cutting parameters follow the “high speed, low feed” principle: spindle speed 1500-3000 rpm, feed rate 0.1-0.3 mm/r, depth of cut ≤0.5 mm, to reduce heat accumulation and prevent material melting.

Machining Path Planning

For CNC machined ABS parts, layered cutting is required to control cutting forces. For complex cavities, helical cutting is used to prevent tool breakage. Optimizing the toolpath reduces idle travel. For example, contour milling is used in mobile phone casing machining to improve surface quality.

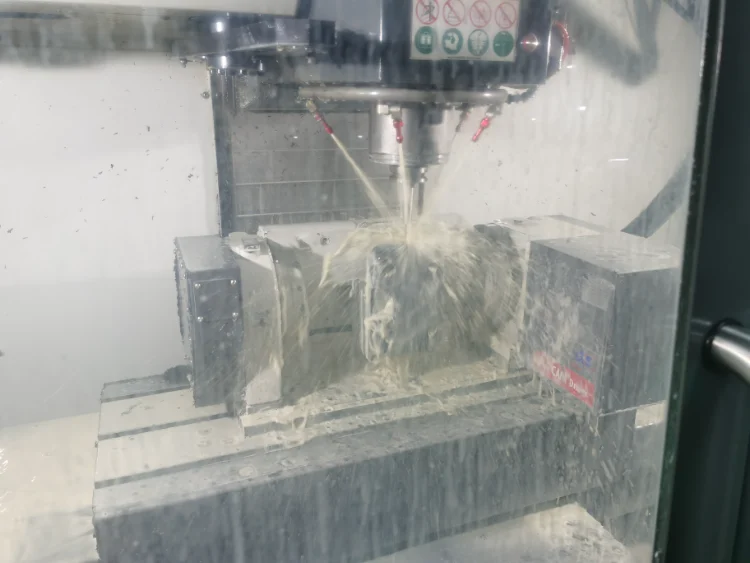

Cooling and Chip Removal

Compressed air cooling is sufficient for CNC machined ABS parts machining. For deep cavities, a pecking milling method is needed to remove chips and prevent accumulation that could lead to machining errors.

Precision Control and Tolerance Standards for ABS Parts

Precision control for CNC machined ABS parts requires consideration of material pretreatment, machining processes, and inspection methods. ABS should be dried at 80℃ for 2-4 hours before machining, reducing the moisture content from 0.2-0.4% to below 0.1%, improving machining stability.

Tolerance Grade Selection

CNC machined ABS parts typically use ISO 2768 M-grade tolerances (±0.1mm for linear dimensions ≤30mm). Precision mating parts use F-grade tolerances (±0.05mm). Due to the high coefficient of thermal expansion of ABS (8×10⁻⁵/℃), the processing environment temperature must be controlled within ±2℃.

Machining Error Compensation

For CNC machined ABS parts, machining error compensation measures include using rigid fixtures to enhance support, optimizing cutting parameters to reduce cutting forces, and using layered cutting to release internal stress. For thin-walled structures, climb milling with reduced feed rate is recommended.

Quality Inspection Methods

In addition to conventional measuring tools, a coordinate measuring machine (CMM) can be used for inspecting complex curved surfaces on CNC machined ABS parts. Because ABS exhibits stress relaxation, it is recommended to wait 24 hours after machining before inspection, at which point the dimensions have stabilized.

Surface Finish and Appearance Enhancement Solutions

Surface finish of CNC machined ABS parts affects product aesthetics and performance. Sandblasting can achieve a surface roughness of Ra 1.6-3.2μm, removing tool marks and providing a substrate for coating adhesion.

Coating Process

CNC machined ABS parts are recommended to use acrylic or polyurethane coatings. High-gloss products use a three-layer system of “primer + color paint + clear coat,” achieving a mirror effect with Ra≤0.8μm after polishing. Plasma etching or flame treatment is required before coating to activate the surface and improve coating adhesion.

Special Surface Effects

CNC machined ABS parts can achieve a metallic texture through vacuum plating, complex textures through in-mold decoration (IMD) technology, and antibacterial coatings for medical applications to meet continuous antibacterial requirements.

Surface Quality Control

The surface quality of CNC machined ABS parts needs to be controlled for roughness, color difference (ΔE≤1.5), adhesion (cross-cut test ≥4B), and weather resistance. Standard samples should be made before mass production, and UV aging tests are required for outdoor applications.

Typical Application Cases and Industry Solutions

ABS material are widely used in multiple industries. In the electronics industry, smartphone casings and laptop structural components are machined from 1.5mm thick ABS sheets to achieve complex three-dimensional curved surfaces and interface holes. The surface is treated with sandblasting and matte spraying, balancing lightweight and tactile feel.

Automotive Industry

ABS parts are widely used in automotive interiors, such as dashboards, door panels, and center consoles. A new energy vehicle’s center console bracket is machined from ABS+PC alloy, achieving a 0.05mm assembly tolerance. Vacuum adsorption fixtures are used during machining to prevent thin-wall deformation.

Medical Equipment Field

Medical-grade ABS parts must meet high precision and biocompatibility requirements. A surgical instrument tray is machined from food-grade ABS, with a surface that can withstand 134℃ high-temperature sterilization and has passed ISO 10993 biocompatibility testing.

Industry-Specific Solutions

ABS material offers industry-specific solutions: Lightweight aerospace structural components utilize topology optimization design; high-strength protective shells for the security industry feature enhanced impact resistance through special reinforcing ribs. A hybrid CNC and 3D printing manufacturing model is suitable for the rapid production of small batches of complex parts.

Summary

This article systematically elaborates on the key technical points of CNC machining of ABS parts, including ABS material properties (density 1.04-1.06 g/cm³, impact strength 20-40 kJ/m²), machining parameters (speed 1500-3000 rpm, feed rate 0.1-0.3 mm/r), and industry applications (electronic housings, automotive interiors, etc.). It also emphasizes achieving high-quality CNC ABS shell production through process optimization and precision control (ISO m-level ±0.1 mm tolerance).

FAQ of cnc machined abs part

What are the material purity requirements for CNC machining ABS parts?

Material purity is crucial. High impurities accelerate tool wear, affect accuracy, and cause surface defects. High-purity, stable-quality ABS material should be selected to ensure part quality.

How to choose cutting tools for CNC machining ABS parts?

ABS is soft. Use specialized, sharp plastic cutting tools, such as double-edged spiral end mills, to reduce cutting forces, prevent deformation and burrs, improve chip removal, and increase efficiency and quality.

What is the accuracy level for CNC machining ABS parts?

Accuracy is typically ±0.05mm or even higher. It is affected by various factors; optimization can ensure accuracy.

How to perform surface treatment on CNC-machined ABS parts?

Spray coating can change color and increase wear and corrosion resistance; electroplating provides a metallic luster and increases hardness; silkscreen printing and hot stamping add markings and patterns.

For small-batch production, what are the advantages of CNC machining of ABS parts compared to injection molding?

No mold required, shorter cycle time, faster delivery; saves mold costs, reduces costs and controls risks; flexible, adapts to design changes.