Understanding surface grinding cost is essential for manufacturers, engineers, and procurement teams who depend on precision-ground components. Whether you’re producing tooling plates, mold bases, metal fixtures, or high-tolerance industrial parts, the final budget often depends on how accurately you estimate the surface grinding cost before placing an order.

This guide explains the core factors affecting cost, the different grinding methods available, and how materials, services, and supplier capabilities play a direct role in the overall surface grinding cost of your project.

Factors That Influence Surface Grinding Cost

Several variables can cause the surface grinding cost to increase or decrease. Understanding these helps you forecast budgets more accurately.

Workpiece Size and Thickness

Large plates and long components require longer machine time and more setup effort. Thin parts also require special techniques to avoid warping. Both situations increase surface grinding cost.

Tolerance and Flatness Requirements

If your part requires:

Very tight thickness control

Extremely flat surfaces

Mirror-like finishes…

the grinding operator must run slower passes, use higher-grade wheels, and conduct additional inspections. Each step raises the surface grinding cost.

Part Quantity

One-off jobs often have the highest cost per piece.

Batch production, however, allows the operator to optimize setups, reducing the total surface grinding cost and the surface grinding price per unit.

Surface Finish Level

A standard industrial finish is typically inexpensive.

A polished finish with extremely low roughness (Ra) requires more time and finer wheels, increasing the surface grinding cost accordingly.

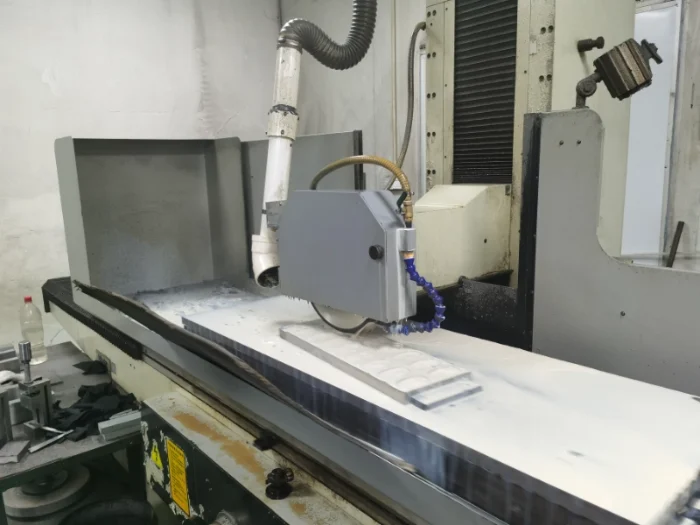

Surface Grinding Types and Their Impact on Cost

Different surface grinding types are suitable for different applications. Selecting the wrong method can unnecessarily increase the surface grinding cost, while choosing the right one helps shorten machine time and stabilize pricing.

Peripheral Surface Grinding

This uses the outer rim of the grinding wheel.

Ideal for long surfaces and high material removal.

Often delivers the most efficient surface grinding price for large parts.

Plunge Surface Grinding

Used for grinding specific regions without table movement.

Suitable for steps, grooves, and profile features.

Usually increases surface grinding cost due to slower feeds.

Rotary Surface Grinding

A rotating table paired with a vertical spindle.

Best for large plates or tooling blocks.

Efficient for high-volume stock removal, lowering overall surface grinding cost.

Double-Disc Grinding

Simultaneously grinds both sides.

Excellent for mass production of parallel components.

Provides the lowest per-piece surface grinding price in large batches.

How Surface Grinding Metal Material Affects Pricing

The type of surface grinding metal material you choose dramatically influences the final surface grinding cost.

Common Materials and Their Cost Impact

Mild steel (1018 / 1020): Easy to grind, lowest cost.

Tool steel (D2, O1, A2, H13): Hard materials require slower passes, increasing cost.

Stainless steel (304 / 316 / 420): Generates more heat; adds to machine time.

Carbide: Requires diamond wheels; premium surface grinding cost.

Why Metal Hardness Matters

Harder metals wear wheels faster and require lower feed rates. This extends processing time, directly influencing the surface grinding price.

Surface Grinding Plastic Material Considerations

Although less common, some engineering plastics also undergo grinding. The behavior of surface grinding plastic material is very different from metals, and this difference significantly affects the surface grinding cost.

Plastics That Can Be Ground

POM (Delrin)

PEEK

Nylon

Acrylic (PMMA)

Polycarbonate

Cost Challenges of Grinding Plastics

Plastics melt easily under heat.

They require lighter passes and careful coolant flow.

They may warp if internal stress is released during grinding.

These complexities often increase the surface grinding cost for plastic parts compared with metal parts of similar size.

Evaluating a Surface Grinding Service for Cost Efficiency

Choosing the right surface grinding service can save both time and money. A competent service provider not only delivers accurate finishes but also offers cost-controlled solutions based on machinery, expertise, and workflow.

What a Professional Service Should Provide

Transparent surface grinding price structure

Guidance on material selection

Recommendations for tolerance optimization

Experience with both metals and plastics

Inspection capabilities for flatness and roughness

A reliable surface grinding service can often reduce your total grinding cost by adjusting tooling, optimizing clamping, or recommending alternative grinding types.

Choosing the Best Surface Grinding Company to Control Cost

The supplier you choose affects consistency, lead time, and overall surface grinding cost. A good surface grinding company combines advanced machinery with skilled operators to deliver reliable results.

What to Look for in a Grinding Company

Modern machines with precise magnetic tables

Proven experience with your specific material

Documented workflow for tolerances

In-house testing tools like CMM, micrometers, and profilometers

Ability to handle both prototype and large-volume production

A highly capable surface grinding company minimizes the risk of rework, which keeps your total surface grinding cost predictable and low.

Understanding Surface Grinding Price Models

Manufacturers typically quote surface grinding price using one of several methods. Knowing these helps you choose the most cost-effective option.

Common Pricing Methods

Hourly Rate

Used for large parts or complex tolerances

Usually $60–$120/hr

Per-Piece Pricing

Ideal for small or medium parts

$3–$40 per unit depending on complexity

Per-Project Cost

Used for tooling plates, mold bases, and large blocks

Price depends on total work time and finish requirements

Why Prices Vary

Different materials require different wheels

Tough geometries may need custom fixtures

High precision increases inspection time

All of these variations affect the overall surface grinding cost you end up paying.

How to Reduce Your Surface Grinding Cost

While many factors increase cost, you can also lower your total surface grinding cost with strategic decisions.

Practical Ways to Save

Keep tolerances realistic

Choose the proper grinding method

Pre-machine parts close to final dimensions

Order in batches to reduce per-unit cost

Discuss alternative materials with your supplier

These actions often reduce the total surface grinding price by 10–40%.

Conclusion

The surface grinding cost of any project depends on tooling method, material type, tolerance needs, production volume, and the capabilities of your chosen supplier. By understanding the differences between surface grinding types, evaluating the right surface grinding service, and selecting a reliable surface grinding company, you can control both precision and overall pricing.

Material choice—whether surface grinding metal material or surface grinding plastic material—also plays a key role in determining the final surface grinding cost. With informed planning and the right grinding partner, you can achieve excellent surface flatness, accuracy, and consistency at a competitive surface grinding price.

If you’ve finished reading this article and would like to learn more about surface grinding and pricing, please contact Weldo. We’ll get back to you as soon as possible.

FAQ of surface grinding cost

What factors influence surface grinding cost?

Surface grinding cost is mainly influenced by part size, material hardness, required tolerances, surface finish level, and production quantity. Harder metals, tight flatness and complex shapes increase cost.

How much does surface grinding typically cost?

Surface grinding cost varies by region and equipment, charged hourly or per piece. Typical rates are 60–120 usd/hour or 3–40 usd/part. Large or precision parts may cost more.

Can choosing the right material reduce surface grinding cost?

Yes. Choosing easy-to-grind materials like mild steel can lower cost. Hard alloys, stainless steel, etc., increase cost due to more grinding time and wheel wear.

Does the type of surface grinding method affect cost?

Yes. Different grinding methods affect cost. Rotary and double-disc grinding are more efficient for large or high-volume parts, lowering cost per piece.

How can I reduce my surface grinding cost for a project?

Optimize tolerances, batch parts, pre-machine close to final dimensions, choose a shop with proper equipment, and pick an experienced provider to reduce cost.