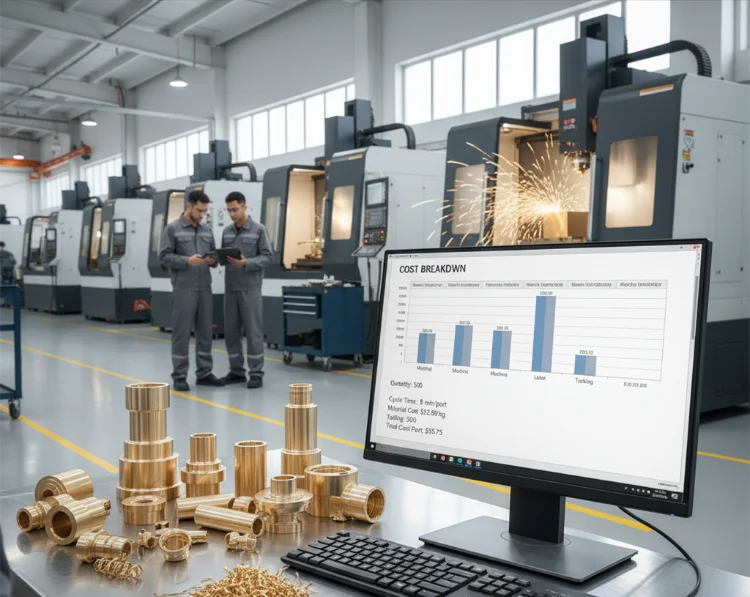

Brass CNC machining cost is one of the most important factors for companies sourcing precision components made from copper alloys. Brass is known for its excellent machinability, corrosion resistance, and smooth surface finish, making it ideal for complex and high-volume CNC projects. Because of these advantages, many industries rely on brass CNC machining parts for electronics, plumbing, mechanical assemblies, aerospace components, automotive connectors, and custom hardware. Companies often compare prices between local suppliers and a china brass cnc machining factory, especially when planning wholesale brass cnc machining for long-term production.

Understanding brass material grades, machining difficulty, standard classifications, surface treatment options, and end-use applications is essential for accurately estimating brass CNC machining cost. Whether a project requires simple turning or high-precision aerospace cnc brass machining, choosing the correct brass alloy structure heavily influences the final price.

Key Factors That Influence Brass CNC Machining Cost

Brass CNC machining cost varies depending on engineering, materials, and production requirements.

1. Brass Alloy Type

Different brass grades affect tool load, cutting speed, and finish quality.

Free-cutting brass offers the lowest machining cost.

High-strength brass increases machining time and affects pricing.

2. Part Complexity

Deep grooves, thin walls, threads, micro-holes, and tight tolerances require slower feeds and more passes.

This directly increases brass CNC machining cost.

3. Finishing Requirements

Polishing, plating, brushing, or special surface coatings add additional processes and cost.

4. Order Quantity

Large orders reduce unit cost significantly, especially with wholesale brass cnc machining.

5. Supplier Location

A china brass cnc machining factory typically offers more competitive pricing due to higher automation and efficient production lines.

U.S. Brass Grades Used in CNC Machining (UNS Standard)

U.S. brass standards follow the Unified Numbering System (UNS), which affects machining performance and cost.

C360 Brass (Free-Cutting Brass)

The most common brass used for CNC machining.

Excellent machinability and low cost.

Perfect for high-volume brass CNC machining parts.

C260 Brass (Cartridge Brass)

Highly formable and corrosion resistant.

Used for decorative parts, connectors, and fluid fittings.

C280 Brass

Strong and ductile.

Common for electrical terminals and architectural hardware.

C464 Brass (Naval Brass)

High corrosion resistance in seawater applications.

Used for valves, pump shafts, and marine hardware.

European Brass Grades Used in CNC Machining (EN Standard)

Europe uses EN (CW series) brass designations.

CW614N (Equivalent to C360)

Ideal for turning, milling, and high-speed production.

Most cost-efficient for CNC machining.

CW508L (Equivalent to C260)

Used for connectors, electronic parts, and stamped components.

CW602N (DZR Brass)

Dezincification-resistant.

Perfect for water systems, plumbing, and fluid controls.

CW721R (High-Strength Brass)

Stronger alloy for mechanical and industrial applications.

Common Surface Finishing Options for Brass CNC Machining

Surface finishing helps improve appearance, corrosion resistance, and performance.

Finishing choice affects brass CNC machining cost.

1. Polishing

Creates a smooth, shiny surface.

Used for decorative hardware and visible components.

2. Electroplating (Nickel, Chrome, Gold)

Enhances corrosion resistance.

Ideal for electronics and high-end mechanical parts.

3. Brushed Finish

Creates uniform directional lines.

Used for consumer electronics and premium hardware.

4. Passivation / Anti-Oxidation Coating

Prevents oxidation and tarnishing.

Useful for plumbing and fluid systems.

5. Sandblasting / Matte Finish

Reduces glare and enhances grip.

Popular for machinery parts and handheld devices.

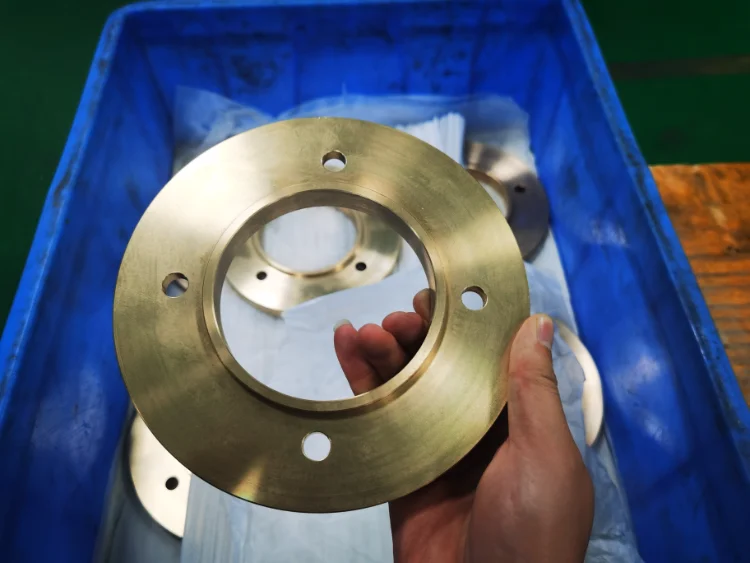

Common Applications of Brass CNC Machining Parts

Different industries choose brass depending on strength, electrical conductivity, or corrosion resistance.

Electrical & Electronic Components

Terminals, sockets, pins, power connectors.

Requires tight tolerance and stable conductivity.

Plumbing and Water Systems

Adapters, couplings, valves, shower hardware.

Brass resists corrosion and mineral buildup.

Automotive & Mechanical Components

Bushings, gears, transmission components.

Brass reduces friction and improves durability.

Aerospace CNC Brass Machining

High-precision inserts, fittings, sensor housings.

Requires certified materials and advanced machining.

Industrial OEM Components

Custom brass cnc machining provides tailored parts for machinery, instruments, and automation systems.

Why Many Brands Choose China Brass CNC Machining Factory

A china brass cnc machining factory offers:

High-precision automated machinery.

Lower brass CNC machining cost due to efficiency.

Fast mass-production capabilities.

Professional quality systems with CMM inspection.

Support for prototypes and custom brass cnc machining projects.

Why Choose Weldo for Cost-Optimized Brass CNC Machining

Weldo provides competitive brass CNC machining cost for small, medium, and high-volume orders.

We support U.S. and EU standard materials including C360, C260, C464, CW614N, CW508L, and more.

Our expertise covers brass CNC machining parts, aerospace cnc brass machining, and complex custom components.

We offer polishing, electroplating, brushing, sandblasting, and full post-processing services.

Weldo helps customers reduce machining cost through engineering optimization and efficient production workflows.

Conclusion

Brass CNC machining cost depends on alloy selection, machining complexity, finishing requirements, and production scale.

Understanding U.S. and European brass classifications helps engineers make informed choices.

Whether you need aerospace-grade precision, wholesale brass cnc machining, or fully custom brass CNC machining parts, the right factory ensures quality, efficiency, and cost control.

If you need accurate pricing, engineering support, or detailed cost analysis, Weldo is ready to help. Contact us for professional brass CNC machining cost evaluations and custom part quotes.

FAQ of brass cnc machining cost

What influences brass CNC machining cost the most?

Material grade, machining complexity, finishing requirements, and order volume.

Which brass alloys are cheapest to machine?

C360 and CW614N offer the best machinability and lowest cost per unit.

Does surface finishing affect brass CNC machining cost?

Yes. Polishing, plating, brushing, and sandblasting add extra processing fees.

Can I request customized brass components?

Absolutely. Weldo provides custom brass cnc machining for OEM parts, prototypes, and mass production.

Is brass suitable for aerospace-level precision?

Yes. With aerospace cnc brass machining, brass can meet strict tolerance and performance standards.