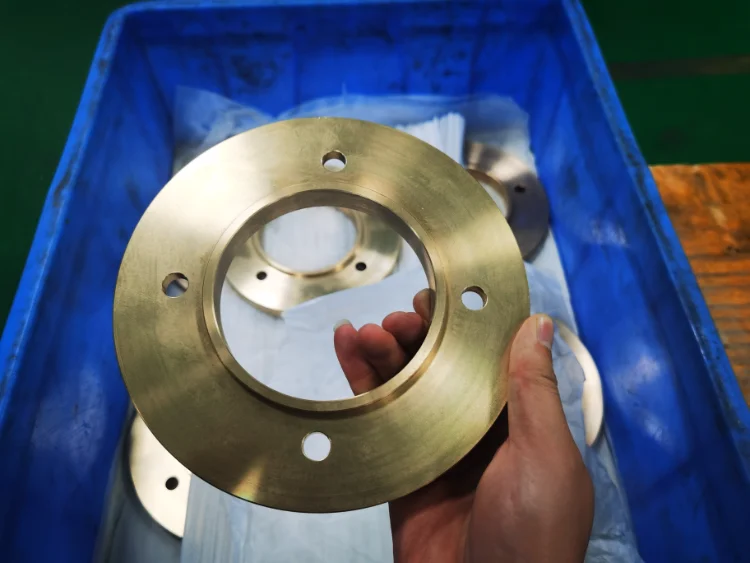

Developing functional prototypes that require strength, wear resistance, and dimensional stability often leads engineers to choose cnc machining bronze prototype solutions. Bronze is well known for its exceptional durability, corrosion resistance, and smooth machinability, making it ideal for precision prototypes in aerospace, automotive systems, industrial machinery, and engineering instrumentation. Whether you need small functional components or complex test assemblies, bronze CNC prototyping offers stability and reliability unmatched by many other metals.

Why CNC Machining Bronze Prototype Solutions Matter

The growing demand for cnc machining bronze prototype production is driven by specific performance requirements. Bronze provides unique mechanical characteristics that allow prototypes to perform closer to production-level components, enabling accurate testing and validation.

Mechanical Benefits of Bronze in Prototyping

- Outstanding wear and fatigue resistance

- Self-lubricating properties (depending on alloy)

- High dimensional stability

- Excellent corrosion and salt-spray resistance

- Smooth cutting performance for detailed features

These advantages make bronze cnc prototype machining suitable for industrial-grade testing, long-term evaluation, and parts requiring repeated friction or rotation.

Material Options for CNC Machining Bronze Prototype Manufacturing

Bronze is not a single alloy but a category of copper-based materials with different mechanical and chemical properties. When selecting the best alloy for a cnc machining bronze prototype, engineers should consider load strength, friction requirements, electrical conductivity, and environmental exposure.

1. C932 (SAE660) Bearing Bronze

Features

- High wear resistance

- Good load-carrying capability

- Excellent machinability

Ideal For

- Bushings

- Bearings

- Sleeve components

- Industrial rotating parts

A top choice for bronze machining prototype parts requiring friction reduction.

2. C954 Aluminum Bronze

Features

- Exceptional strength and hardness

- Superior corrosion resistance

- Resistant to shock and heavy stress

Applications

- Marine equipment prototypes

- Heavy-duty mechanical arms

- Tooling fixtures

- Structural supports

Commonly used in custom bronze cnc machining for engineering-grade prototypes.

3. C863 Manganese Bronze

Features

- High impact resistance

- Excellent hardness

- Suitable for rugged environments

Applications

- Gears

- Automotive bushings

- Industrial couplings

An ideal alloy for bronze cnc machining service where durability is critical.

4. Phosphor Bronze (C510 / C544)

Features

- Strength combined with elasticity

- High fatigue resistance

- Exceptional corrosion resistance

Applications

- Electrical terminals

- Springs

- Connectors

- High-precision sensor parts

Common for lightweight structural prototypes requiring both flexibility and strength.

CNC Machining Bronze Prototype Techniques and Capabilities

A successful cnc machining bronze prototype project requires a combination of advanced machining processes and close tolerance control.

High-Precision Milling and Turning

Key Benefits

- Excellent surface finishes

- Precise dimensional control

- Stable performance in rotational parts

Most bronze cnc prototype machining projects involve both multi-axis milling and turning.

Fine Hole Drilling & Threading

Bronze alloys maintain edge strength and thread stability, allowing reliable threaded prototypes for:

- Mechanical assemblies

- Connectors

- Fastening components

Surface Finishing for Bronze Prototypes

Bronze machining supports multiple finishes to improve part performance:

- Polishing → for friction components

- Passivation → strengthens corrosion resistance

- Machined satin finish → common for mechanical fittings

- Oil impregnation → for self-lubricating bronze bearings

These finishing techniques enhance the functionality of bronze machining prototype parts.

Applications for CNC Machining Bronze Prototype Components

Aerospace Structural Testing

Bronze prototypes are used in:

- Actuator components

- Load-bearing connectors

- High-wear bushings

They ensure reliability under vibration, temperature shifts, and long-term stress.

Automotive System Prototyping

- Gear models

- Steering bushings

- Drivetrain test parts

Bronze supports durability testing in dynamic automotive systems.

Industrial Machinery and Robotics

- Linear motion parts

- Rotating assemblies

- Wear plates

The self-lubricating properties of bronze make prototypes more stable in mechanical motion applications.

Marine Equipment Development

Because bronze is corrosion-resistant, it’s widely used for:

- Pump housings

- Propulsion components

- Marine hardware prototypes

This makes custom bronze cnc machining valuable for saltwater conditions.

Advantages of CNC Machining Bronze Prototype Manufacturing

Excellent Dimensional Accuracy

Machining bronze enables prototypes within precise tolerances suitable for engineering evaluation.

Long-Term Durability

Bronze prototypes can endure harsh conditions during testing without deformation.

Stable Mechanical Behavior

Bronze offers consistent stress resistance, making prototypes ideal for full-load testing.

Better Friction Performance

Ideal for bushings, gears, connectors, and sliding/rotating mechanisms.

Suitable for Both Functional and Aesthetic Prototypes

Bronze’s natural golden color makes it appealing for both industrial and visual design applications.

Cost Factors in CNC Machining Bronze Prototype Production

Several elements influence production cost:

Material Selection

Different bronze alloys vary significantly in price and machinability.

Machining Time

Dense, high-hardness bronzes require slower cutting speeds, increasing production time.

Tolerances and Complexity

The more detailed the geometry, the higher the cost.

Finishing Requirements

Polishing, threading, and corrosion treatments also affect final pricing.

These variables determine the total investment in cnc machining bronze prototype production.

Request CNC Machining Bronze Prototype Quotes — Contact Weldo Machining

Selecting the right manufacturer is essential for achieving accurate, durable, and fully functional bronze prototypes. As a trusted provider of cnc machining bronze prototype solutions, Weldo Machining delivers high-precision machining for C932, C954, C863, phosphor bronze, and other bronze alloys. Whether you need gear prototypes, bearing components, structural test samples, or intricate mechanical assemblies, our engineering team provides reliable quality, fast turnaround, and competitive pricing.

Contact Weldo Machining today for detailed quotations, technical support, and professional guidance regarding any cnc machining bronze prototype requirements.

FAQ of cnc machining bronze prototype

What is a CNC machining bronze prototype used for?

It is used to test mechanical strength, wear resistance, and structural performance in industries such as aerospace, automotive, and robotics.

Which bronze alloys are best for prototyping?

C932 bearing bronze, C954 aluminum bronze, C863 manganese bronze, and phosphor bronze are the most commonly used options.

Why choose bronze for prototype components?

Bronze offers exceptional wear resistance, durability, corrosion protection, and dimensional stability—ideal for functional testing.

How accurate can bronze CNC prototypes be?

Tolerance levels typically range from ±0.01–0.05 mm, depending on geometry and machining equipment.