Choosing a professional peek cnc machining manufacturer is essential for industries requiring high-performance plastic components with exceptional durability, heat resistance, and dimensional stability. PEEK (polyether ether ketone) is one of the most advanced engineering polymers used today, but machining it correctly requires specialized tools, controlled cutting strategies, and strict temperature management. This guide explains how PEEK machining works, what to consider during production, and how to select the right manufacturer for your project.

Why Working With a Skilled PEEK CNC Machining Manufacturer Matters

A qualified peek cnc machining manufacturer understands the unique challenges of cutting, shaping, and finishing PEEK. Compared with standard plastics, PEEK demands higher precision, slower feed rates, and advanced cooling control. When handled by inexperienced suppliers, problems such as warping, internal stress, dimensional drift, and surface burns can easily occur.

Key Advantages of Choosing an Experienced Manufacturer

- Deep understanding of heat-management techniques

- Knowledge of virgin PEEK, reinforced PEEK, and medical-grade PEEK

- Ability to maintain ±0.01–0.02 mm tolerances

- Specialized tooling to handle tough polymer fibers

- Advanced inspection capabilities for demanding industries

Working with a reliable cnc machining peek supplier ensures consistent accuracy and stable long-term performance.

Key Material Options a PEEK CNC Machining Manufacturer Works With

Professional peek material cnc machining factories process the following common grades:

Virgin PEEK

Features

- Pure polymer

- Excellent chemical & thermal stability

- Ideal for aerospace, electronics, semiconductors

Glass-Filled PEEK

Features

- 30% glass reinforcement

- Higher rigidity

- Suitable for industrial bearings and housings

Carbon-Filled PEEK

Features

- High strength-to-weight ratio

- Reduced friction

- Often used in wear-resistant parts, pump components, and sliding mechanisms

Guide: How a Professional PEEK CNC Machining Manufacturer Works

Below is an efficient workflow used by leading peek cnc machining manufacturer teams.

Step 1 — Material Preparation

- Pre-drying PEEK pellets or sheets to remove moisture

- Cutting stock to proper blank sizes

- Verifying grade certification

Step 2 — CNC Milling or Turning Strategy Setup

- Selecting carbide tools and high-heat-tolerance inserts

- Setting low feed rates and controlled spindle speeds

- Designing tool paths to minimize chip heat accumulation

Step 3 — Heat Control During Machining

- Using air cooling or minimal-quantity lubrication

- Avoiding continuous heavy cutting that softens PEEK

- Maintaining dimensional stability throughout production

Step 4 — Precision Finishing

- Surface polishing

- Edge deburring

- Dimensional inspection

Step 5 — Final Quality Check

- Checking tolerance accuracy

- Verifying structural integrity

- Conducting stress and deformation inspections

This workflow reflects the high-level methodology of a modern custom peek cnc machining factory.

Important Machining Tips for PEEK CNC Manufacturing

A professional peek cnc machining manufacturer always considers the following technical tips:

1. Strict Temperature Management

PEEK softens when overheated. Machinists must:

- Use controlled cooling

- Maintain consistent feed rates

- Ensure proper chip evacuation

2. Use High-Wear-Resistance Tools

Carbide tools or diamond-coated cutters reduce:

- Burr formation

- Dimensional distortion

- Rapid tool wear

3. Avoid Internal Stress

Improper machining can cause:

- Warping

- Cracking

- Tolerance instability

Manufacturers avoid this through staged cutting techniques and post-machining stress relief.

4. Slow Cutting Speeds for Reinforced Grades

Glass-filled and carbon-filled PEEK require:

- Reduced cutting speeds

- Sharp tooling

- More frequent inspections

5. Maintain Clean, Polished Surfaces

Especially for medical, semiconductor, or sealing parts:

- Polishing reduces friction

- Clean edges improve functionality

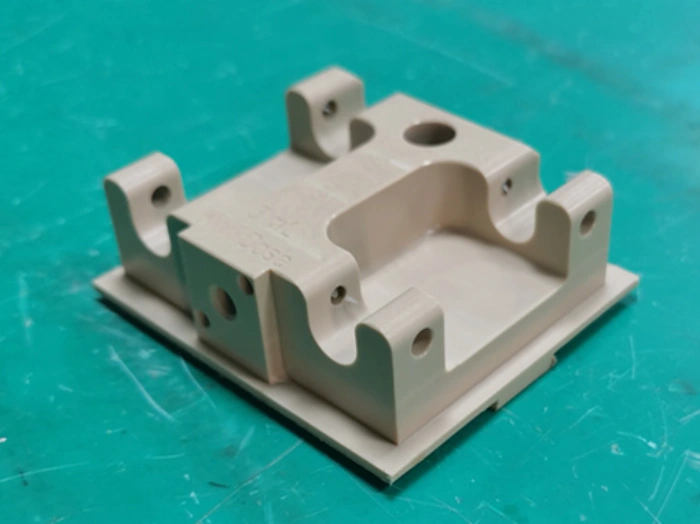

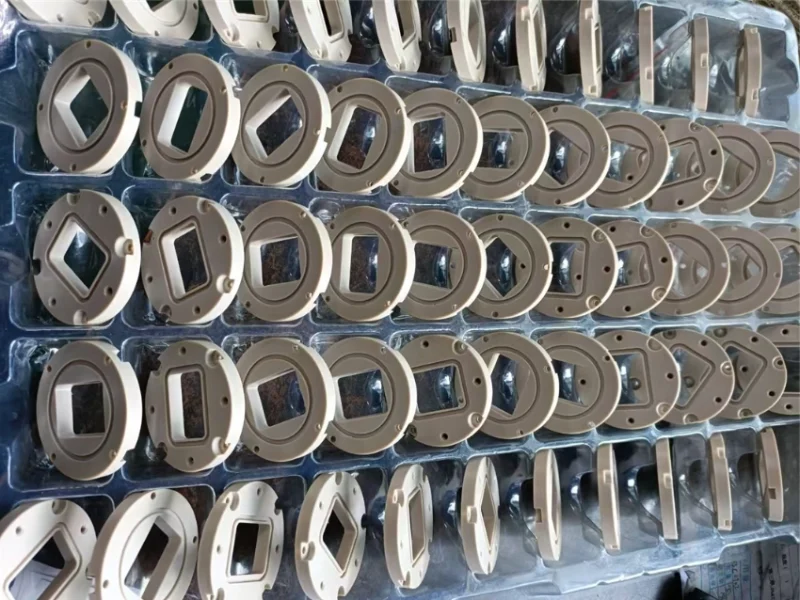

Common PEEK CNC Machined Parts Produced by Manufacturers

Industries choose peek cnc machining manufacturer services for components such as:

1. Aerospace Components

- Insulation blocks

- High-temperature brackets

- Lightweight structural parts

2. Medical Device Parts

- Sterilization-resistant brackets

- Surgical tool handles

- Implant-safe elements

3. Semiconductor Equipment Parts

- Wafer holders

- Precision insulators

- Heat-stable alignment fixtures

4. Automotive & EV Parts

- High-voltage insulators

- Precision bushings

- Transmission guides

5. Oil & Gas System Components

- Sealing parts

- High-pressure valve inserts

- Corrosion-resistant brackets

These industries rely heavily on peek material cnc machining factories because of PEEK’s strength and chemical resistance.

How to Choose the Right PEEK CNC Machining Manufacturer

When selecting a peek cnc machining manufacturer, evaluate these factors:

1. Experience With Reinforced PEEK Grades

Ask whether the supplier can process:

2. Tolerance Control Capability

For aerospace or semiconductor needs, the manufacturer should maintain:

- ±0.02 mm or tighter

- Automated CMM inspection

- Multi-stage quality checks

3. Advanced CNC Equipment

A high-quality supplier should have:

- 3-axis / 4-axis / 5-axis CNC mills

- Precision lathes

- Inspection instrumentation

4. Engineering Support

A reliable cnc machining peek supplier provides:

- Design improvement suggestions

- Material grade guidance

- Stress and heat-distortion analysis

5. Flexible Production Volumes

The manufacturer should support:

- Prototype development

- Small-batch production

- Large-volume OEM supply

Why Pricing Varies Between PEEK CNC Machining Manufacturers

PEEK machining cost varies due to:

Material grade (virgin, GF, CF)

Machining time (complexity, thin walls, undercuts)

Finishing (polishing, tolerance verification)

Order quantity (prototype vs bulk)

Inspection requirements (CMM, optical testing)

These factors collectively determine pricing when comparing custom peek cnc machining factory options.

Request Custom PEEK CNC Machining Pricing — Contact Weldo Machining

When you need high-performance PEEK components, partnering with the right peek cnc machining manufacturer ensures precision, stability, and long-term reliability.

Weldo Machining provides advanced PEEK CNC milling, turning, inspection, and engineering support for both prototypes and mass-production orders.

Contact us today for accurate pricing and professional guidance on your PEEK CNC machining project.

FAQ of peek cnc machining manufacturer

Why is PEEK more difficult to machine than standard plastics?

PEEK requires strict heat control, specialized tooling, and slow feed rates due to its hardness and high melting point.

What tolerances can a professional manufacturer achieve with PEEK?

High-end suppliers can maintain ±0.01–0.02 mm depending on part size and grade.

How do I choose the right PEEK CNC machining manufacturer?

Evaluate their experience with PEEK grades, tolerance control, CNC equipment, engineering support, and inspection capability.