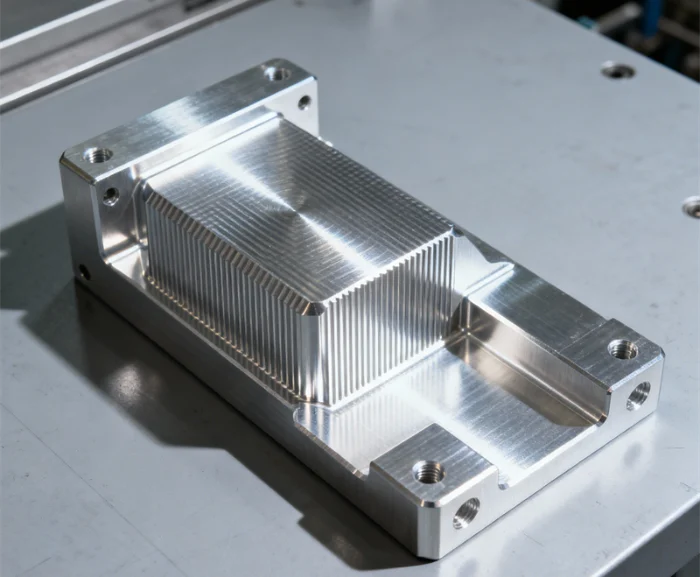

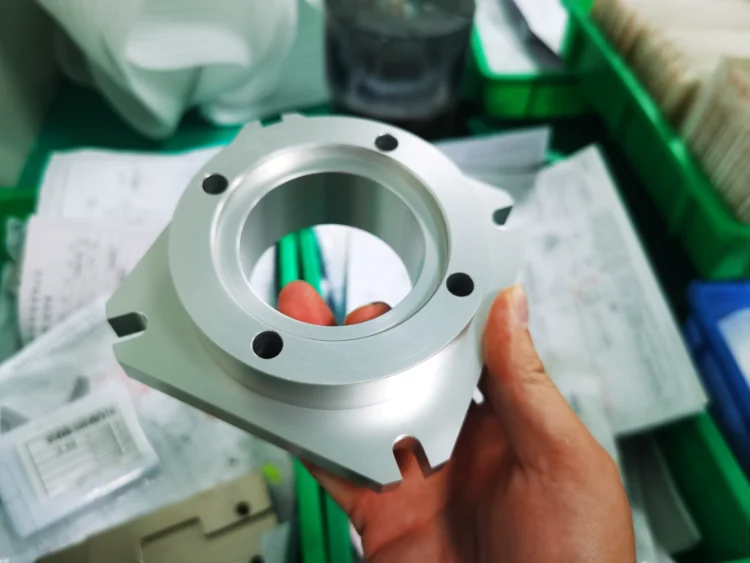

Magnesium CNC machining prototype development is essential for creating lightweight, high-strength parts for electronics, automotive, aerospace, and medical devices. Because magnesium is one of the lightest structural metals, a magnesium CNC machining prototype allows fast testing of structure, assembly, and performance before mass production.

Common Magnesium Materials for Prototyping

Several magnesium alloys are widely used due to their strength and excellent machinability:

- AZ31 – Very lightweight and stable during machining.

Used for electronic housings, brackets, and consumer product prototypes. - AZ61 – Higher strength and good toughness.

Suitable for UAV components and industrial frames. - AZ91 – The most common alloy with a strong strength-to-weight ratio.

Used for aerospace covers, automotive modules, and medical housings. - AM60 – Excellent ductility and impact absorption.

Ideal for safety-related prototype housings. - ZK60 – High strength and fatigue resistance.

Used for aerospace brackets and high-load structural prototypes.

These materials ensure the magnesium CNC machining prototype meets early testing requirements for design validation and lightweight performance.

Machining Processes for Magnesium Prototypes

Typical machining operations include CNC milling, CNC turning, drilling, tapping, fine grinding, and deburring. These support rapid prototyping and magnesium precision machining for structural testing.

Surface Finishing Options

To improve corrosion resistance and appearance:

- Chromate coating

- Conversion coating

- Magnesium anodizing

- Powder coating

- Micro-polishing

Finishing helps protect the magnesium CNC machining prototype before assembly evaluation.

Tolerance Standards

General tolerances range from ±0.01–0.05 mm, while critical surfaces may reach ±0.005 mm, ensuring accurate fit during prototype testing and later mass-production verification.

Machining Guide & Precautions

- Use sharp tools to avoid tearing magnesium

- Maintain controlled feeds to prevent heat buildup

- Remove chips safely, as they are flammable

- Apply coatings quickly to prevent oxidation

- Ensure proper fixturing for thin-wall parts

Why Magnesium CNC Machining Prototype Matters

Prototyping verifies structural behavior, lightweight performance, assembly fit, and manufacturability early in the design cycle. It reduces risk, shortens development time, and lowers overall production cost.

Mass Production Considerations

When moving from prototype to volume production:

- Optimize toolpaths for consistency

- Confirm coating durability for large batches

- Standardize inspections for uniform quality

- Secure stable alloy supply

- Validate fixture systems for repeatability

Conclusion

A magnesium CNC machining prototype is a key step toward reliable, lightweight, high-precision components. From alloy selection to finishing and tolerance control, every stage affects final performance. For expert prototype support or mass-production machining, contact Weldo Machining for technical guidance and a customized quote.

FAQ of magnesium cnc machining prototype

How long does a magnesium CNC machining prototype normally take to produce?

Most prototypes require 3–7 days depending on complexity and finishing.

Can magnesium prototypes be used for thermal testing?

Yes, but alloy selection is important for high-temperature environments.

Is magnesium suitable for medical device prototypes?

Yes—after proper coating, it is widely used in handheld medical housings.

Can threads be directly machined on magnesium?

Yes, though inserts or reinforced threads are recommended for durability.