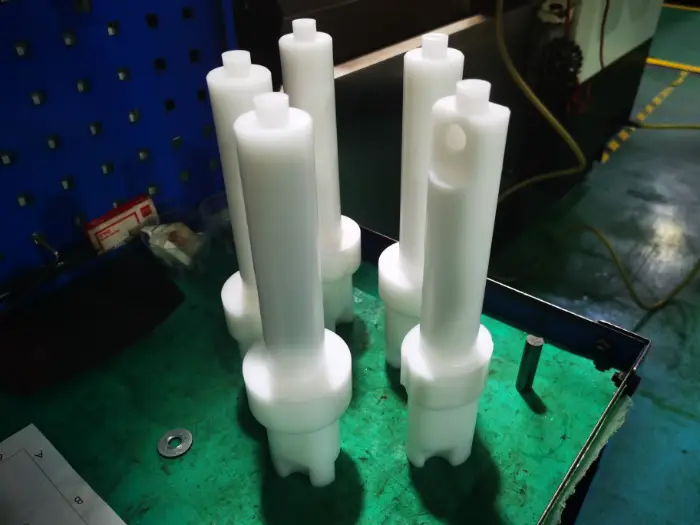

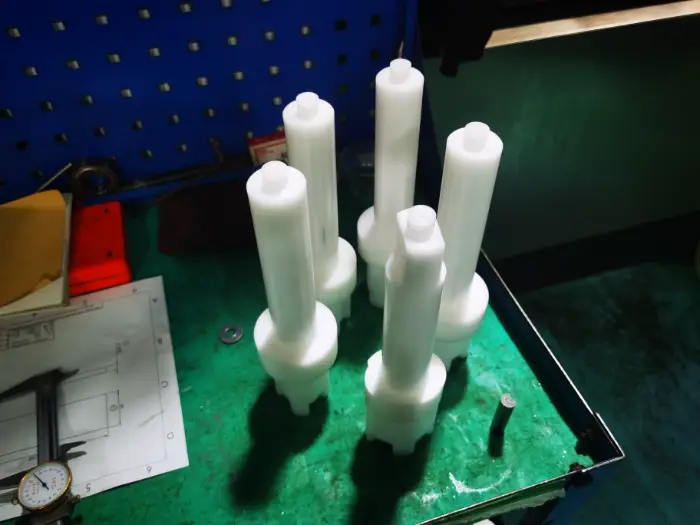

As industries pursue lighter, precise components, evaluating pom connecting rods cost helps determine whether CNC-machined POM rods can replace molded or metal versions. POM provides stability, low friction, and reliable performance for prototypes of piston connecting rods, piston rods, and early v6 or v8 connecting rod layouts, while CNC machining delivers far better accuracy than molding or 3D printing.

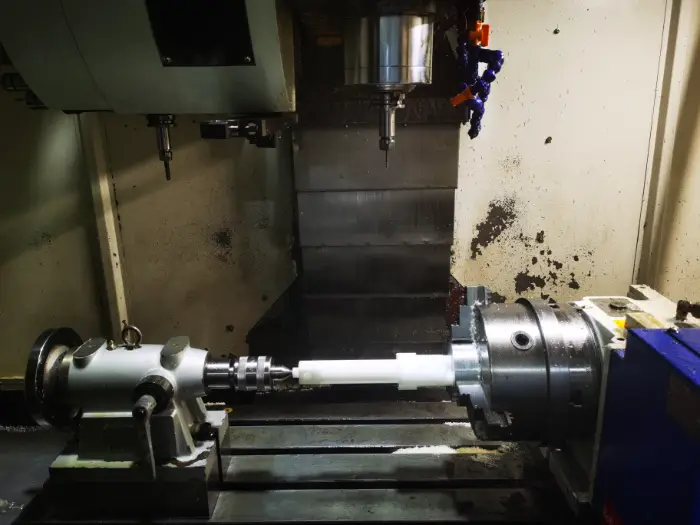

Why CNC Machined POM Connecting Rods Are Superior

CNC machining transforms solid POM stock into precision connecting rods with exceptional dimensional accuracy. For functional prototypes, actuator assemblies, automation equipment, and motion-validation models, CNC machining provides performance advantages unmatched by molding or 3D printing.

1. High Dimensional Accuracy for Precision Motion

CNC machining achieves ±0.02–0.05 mm tolerances—critical for:

- POM piston connecting rods

- Bore alignment in piston rods

- Mechanism prototypes simulating v6 connecting rod motion

- Multi-axis linkage plates requiring precise geometry

Molding suffers from shrinkage and warpage, while 3D printing cannot deliver consistent tolerances.

2. Superior Surface Finish for Low-Friction Performance

A smooth surface is essential for stability and durability in sliding or pivoting assemblies.

CNC machining creates:

- Polished bore surfaces

- Uniform rod ends

- Consistent friction-reducing contact areas

Molded or printed rods usually show layer lines, weld marks, or surface texture that increases friction and accelerates wear.

3. No Internal Stress, Stronger Overall Rod Integrity

CNC machining removes material without inducing thermal or fusion stress. By contrast:

- Injection molding introduces internal tension due to rapid cooling

- Compression molding creates density inconsistencies

- 3D printing produces weak interlayer bonds

CNC-machined rods maintain shape and strength during repetitive operation.

4. Excellent for Prototype Piston Rods and Motion Studies

For engineers testing:

- Piston connecting rods motion

- Linkage geometry

- Early-stage v6 or v8 connecting rod layouts

CNC machining offers fast design changes without tooling investment, reducing development cycles and verification cost.

5. Support for Hybrid Reinforced Rod Designs

CNC machining enables integration of:

- Brass or steel bushings

- Threaded inserts

- Stainless pivots

- Custom-fit pins

This is difficult or impossible with molding unless complex insert-placement tools are created.

CNC Machining vs Other Machining Processes for POM Connecting Rods

Below is a detailed comparison of CNC machining with molding and 3D printing when producing POM rods.

CNC Machining vs Injection Molding

CNC Machining Advantages

- Best dimensional accuracy

- Highest-quality surface finish

- No tooling cost

- Ideal for low and mid-volume production

- Supports reinforced hybrid rods

Injection Molding Advantages

- Lowest unit cost for high-volume runs

- Good for simple, small rods

- Fast cycle time

Injection Molding Limitations

- Expensive mold tooling

- Shrinkage and warpage

- Limited precision

- Surface defects and weld lines

- Not suitable for precision-fit rod ends

Conclusion:

For engineering-grade POM connecting rods, CNC machining is superior unless producing extremely high quantities.

CNC Machining vs 3D Printing

3D printing (FDM/SLS) is useful for basic shape mockups, but has major drawbacks for real functional rods:

3D Printing Limitations

- Weak interlayer bonds

- Poor wear resistance

- Rough surface finish

- Dimensional inaccuracy

- Unsuitable for high-frequency mechanisms

CNC Advantages Over 3D Printing

- 10× greater accuracy

- Stronger solid structure

- Superior sliding performance

- Consistent bore geometry

For any mechanism resembling piston rods, piston connecting rods, or small-scale v6 connecting rod systems, CNC machining is the only viable option.

CNC Machining vs Compression Molding

Compression molding offers lower material waste but suffers from:

- Inconsistent density

- Poor tolerance control

- Limited geometry capability

- Lower-quality surface finish

CNC machining provides predictable, reliable performance.

Structural Advantages Unique to CNC POM Connecting Rods

1. Ideal Bore and Shaft Alignment

Essential for rod-end bearings and motion synchrony.

2. Smooth Ends for Wear Reduction

Enhances lifespan in repetitive motions.

3. Consistent Rod Length and Geometry

Prevents binding, vibration, and misalignment.

4. Complex Shapes and Geometry Freedom

CNC machining enables:

- Reinforced rod ends

- Tapered bodies

- Lightweight cutouts

- Multi-hole layouts

- Rod designs similar to compact v6 connecting rod structures

Cost Factors – What Determines POM Connecting Rods Cost

Understanding pom connecting rods cost helps engineers plan budgets effectively.

1. Complexity

More pockets, rod-end details, and internal curves = longer CNC time.

2. Dimensional Tolerances

High-precision piston rod prototypes cost more.

3. Reinforcement Inserts

Bushings, threaded inserts, or pivot pins add cost.

4. Material Volume

Larger rods require more POM stock.

5. Production Quantity

CNC unit price decreases after 20–50 pcs.

Typical CNC Price Ranges

- Simple rods: $5–10 each

- Medium complexity rods: $12–25

- Reinforced piston connecting rods prototypes: $20–60+

These ranges vary based on geometry and tolerance specifications.

Applications Where CNC POM Rods Outperform Other Processes

Robotics

Lightweight and friction-stable.

Automation

Quiet, smooth action and low lubrication needs.

Fluid-Control Systems

Chemical-resistant POM holds up well against oils and fuels.

Prototype Development

Perfect for validating piston rod geometry before producing metal versions.

When to Choose CNC POM Rods vs Other Methods

Use CNC machining when:

- Rods require precision slide-fit ends

- High cycle life and durability matter

- Prototypes simulate piston connecting rods

- Geometry is complex

- Quantities are moderate

Use injection molding when:

- You need 20,000+ pcs

- Tolerances are relaxed

- Surface quality isn’t critical

Use 3D printing only for:

- Shape studies

- Non-functional mockups

Final Conclusion – Why CNC POM Connecting Rods Deliver the Best Engineering Value

CNC machining produces POM connecting rods with:

- Top-tier accuracy

- Best structural integrity

- Superior wear resistance

- Low friction performance

- Ideal geometry for engineering mechanisms

When evaluating pom connecting rods cost, CNC machining consistently offers the best balance of precision, reliability, and flexibility for prototypes and functional assemblies.

if you want to know more details of cnc machining pom connecting rods,you can feel free to contact with us Weldo machining later