When a design needs structural strength, good corrosion resistance, and clean cosmetics, engineers often choose CNC machining 6082 aluminum prototype parts before committing to production. The prototype validates function, proves tolerance feasibility, and exposes cost/lead-time risks early—while preserving the freedom to iterate.

Requirements That Shape a CNC Machining 6082 Aluminum Prototype

Before chips fly, clarify the decision inputs that drive a successful CNC machining 6082 aluminum prototype.

Define Function and Critical Features

Mark the mating faces, datum scheme, and any feature that must meet ±0.02–0.05 mm. Assign all others as “reference.” This single step often removes unnecessary finishing passes and keeps your first sample on schedule.

Select Temper and Stock

For prototypes, most teams choose 6082-T6 or T651. T651 is stress-relieved and keeps flatness predictable on pocketed plates—ideal for a first trial part where warpage can mask the real fit-up result.

Finish Upfront, Not After

If the design needs black or clear anodize, include it in the prototype plan. Coating growth affects bore fits and thread gauges; planning finish now avoids misleading “fits in lab, fails in field” outcomes during pilot build.

Programming and Tooling—Machinability of 6082

A key reason teams like CNC machining 6082 aluminum prototype work is the alloy’s friendly cutting behavior.

Toolpaths That Respect Thin Walls

Use high-efficiency milling and constant tool engagement, especially for deep pockets. Semi-finish passes relieve stress before the last cut. The result is a trial part that holds flatness without grinding time.

Cutter Library and Coolant Strategy

Carbide end mills with polished flutes and flood coolant deliver reliable chip evacuation in 6082. For small-diameter features, consider minimum-quantity lubrication to improve top-edge integrity—useful when the sample will be bead-blasted then anodized.

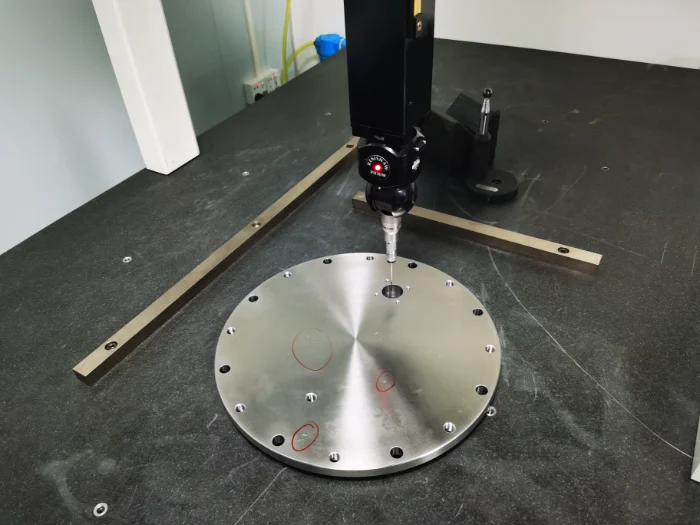

Inspection Planning

Prototype runs benefit from in-process probing and post-process CMM checks only for the critical features. A lean DFM review here keeps cycle time tight while guaranteeing the measurements that matter.

Tolerances, GD&T, and What a Prototype Should Prove

A CNC machining 6082 aluminum prototype is more than a physical sample—it’s a test bench for manufacturability.

Fit, Form, Function

- Bore concentricity to a bearing seat or shaft shoulder validates assembly dynamics.

- Flatness/parallelism across mounting faces determines torque stability and sealing.

- Thread quality after anodizing (with masking or post-tap) proves production feasibility.

Process Capability Signals

If the first trial part is hard to hold, ask whether the challenge is geometry (tool reach), datum strategy, or stock stress. The answer guides design tweaks before committing to small batch.

Surface Finishes That Pair Well with 6082

For prototypes, finishes must be representative but time-sensitive.

Anodizing Options

- Type II clear/black: economical, corrosion-resistant, ideal for validation units.

- Type III hardcoat: abrasion protection for sliding interfaces; plan thickness in bores.

Bead Blast + Anodize

Many teams specify a matte cosmetic. In 6082, a light bead blast hides tool marks and helps the sample present like a customer-facing part. Just account for surface growth in your tolerances.

Selective Masking

For bearing bores and ground pins, mask during anodize or ream/post-tap afterward. Proving this on the CNC machining 6082 aluminum prototype de-risks mass production.

Lead Time, Cost, and How to Quote Prototypes Smartly

The cost of a CNC machining 6082 aluminum prototype is largely driven by setup and programming—not raw material.

What Drives Prototype Price

- Programming and setup (non-recurring).

- Cycle time (toolpaths, reach, rigidity).

- Finishing (bead blast, anodize, masking).

- QA (CMM time, gauge certifications).

Indicative Lead-Time Ranges

- Rapid prototyping: 3–5 business days for simple plates or brackets.

- Complex housings/5-axis: 7–12 days including finish.

- Pilot build (20–50 pcs): 10–15 days with repeatable fixtures.

What to Send for a Fast Quote

A well-structured package gets a realistic price in one pass: STEP/IGES, fully dimensioned PDF with GD&T, tolerances prioritized, material/temper, finish spec and any masked zones, plus one-line small batch plan (“1 pc now; 50 pcs after approval”).

Design Levers That Lower Prototype Risk (and Future Cost)

Use the prototype to de-risk production and compress future lead times.

1) Tool-Friendly Corners

Match pocket radii to standard cutter sizes (e.g., R2.0, R3.0). Your trial part will cut cleaner and faster.

2) Datum Strategy for Two-Sided Completion

Plan datums so the part can be finished in two setups; each avoided flip eliminates stack-up error and NRE time.

3) Wall-Thickness Tuning

Move from 1.0 mm to 1.5 mm when possible. 6082 stiffens nicely; chatter drops and surface finish improves—important when your sample must impress decision makers.

4) Finish Only What Matters

If a cosmetic face will be hidden in assembly, leave it as-machined for the prototype. Reserve bead blast or anodize for exposed surfaces to shorten the validation loop.

5) Thread Strategy

Mask threads before anodize or specify post-tap. Prove both during CNC machining 6082 aluminum prototype so the production traveler is crystal-clear.

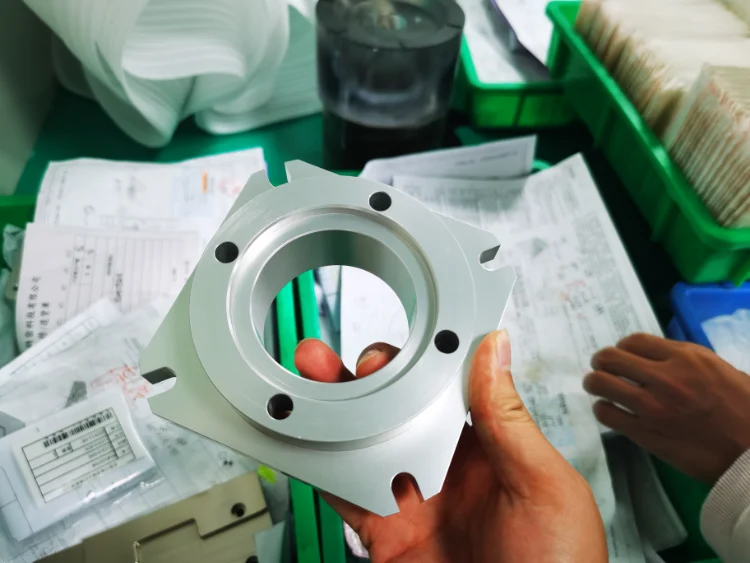

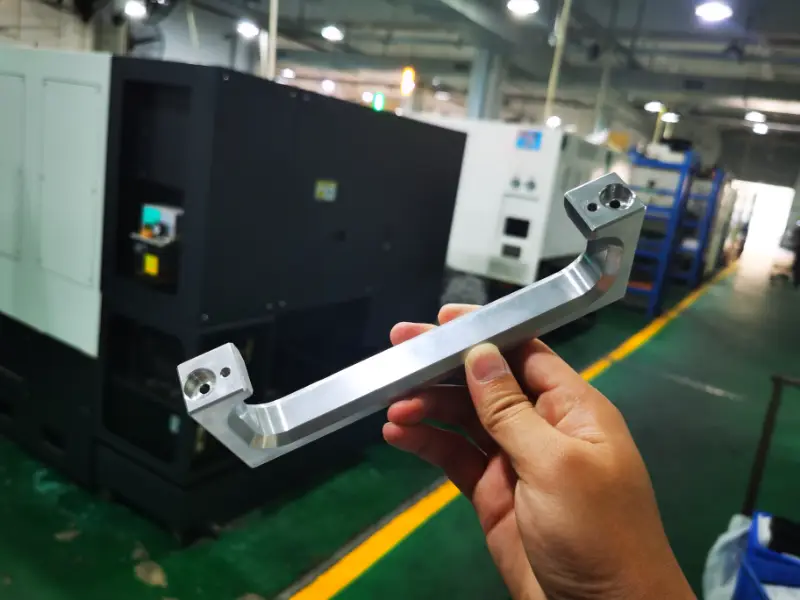

Case Note: Automation Bracket, 6082-T651

- Scope: Two-sided 3-axis milling, deep pocket + counterbored holes

- Finish: Bead blast + black Type II anodize (masked M6 threads)

- Outcome: First sample passed fit-up; minor radius increase allowed faster toolpath. Small batch of 30 pcs delivered in 12 days with identical cosmetics to the prototype.

What to Expect from a Prototype Partner

A competent shop running CNC machining 6082 aluminum prototype work should provide:

- A concise DFM review within 24–48 hours highlighting cycle-time risks.

- CAM screenshots and fixture notes proving the approach.

- Clear measurement plan (what gets CMM vs. calipers).

- Finish coupons if color consistency matters for your pilot build.

- A path to scale: same tools, same fixtures, same traveler—so the first article becomes the production standard.

Why Weldo Machining

Weldo Machining specializes in CNC machining 6082 aluminum prototype programs that transition smoothly into production. We combine fast quoting with manufacturability insight:

- Rapid DFM review and risk-based pricing.

- 3-, 4-, and 5-axis capability; probing and CMM verification of critical features.

- In-house bead blast and coordinated anodizing to keep color stable from trial part to pilot build.

- Flexible small batch options and clear cost curves as volume increases.

Send your STEP and drawing today—we will return a detailed quotation and timeline, plus optional tweaks to cut cycle time while preserving function.

Conclusion

A well-run CNC machining 6082 aluminum prototype program is the fastest way to transform CAD intent into verified function and a credible business case. By planning temper and finish early, focusing GD&T on what matters, and treating the prototype as the rehearsal for production, teams minimize rework and compress launch schedules. When you are ready to move from sample to scale, partner with a shop that designs cost out from day one.

Contact Weldo Machining for a rapid quote, a pragmatic DFM review, and a prototype that is production-ready by design.