A professional surface finish guide is critical for engineers, OEM buyers, and product designers who require reliable CNC machined parts across industrial, medical, aerospace, and consumer applications. This surface finish guide explains not only why surface finish is essential in machining, but also provides a comprehensive overview of all major surface treatment types, their functions, application scenarios, and relative costs.

Why a Comprehensive Surface Finish Guide Is Necessary

A modern surface finish guide goes far beyond basic appearance control. Surface finish directly influences:

- Mechanical performance

- Corrosion and chemical resistance

- Fatigue life and stress concentration

- Assembly accuracy and sealing

- Regulatory and industry compliance

Without a structured surface finish guide, surface treatment selection often becomes inconsistent, over-specified, or cost-inefficient.

Relationship Between Surface Finish and CNC Machining Quality

In CNC machining, surface finish is an output of both process capability and post-machining treatment. A reliable surface finish guide considers:

- Tool path strategy and cutting stability

- Material machinability

- Heat generation and burr formation

- Secondary finishing requirements

Weldo Machining controls surface finish at both the machining and finishing stages to ensure consistency from prototype to production.

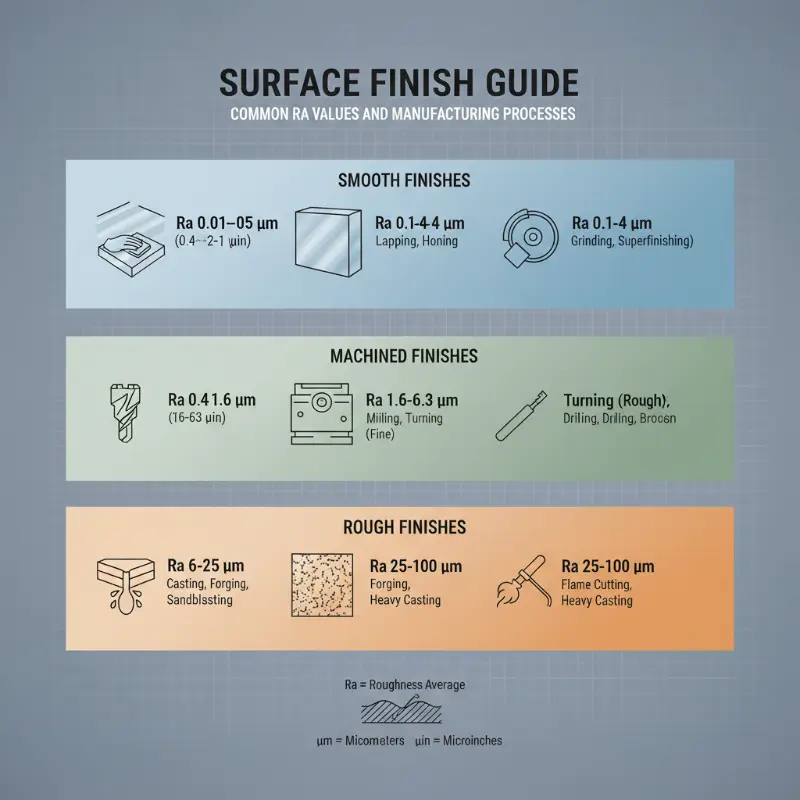

Standard Surface Finish Metrics Used in Industry

A technically correct surface finish guide always references standardized measurements.

Ra (Surface Roughness Average)

- Most common specification on engineering drawings

- Typical CNC ranges: Ra 0.8–6.3 µm

Rz, Rt, and Functional Roughness

- Used in sealing, sliding, or fatigue-sensitive parts

- Often required in aerospace and automotive applications

Clear roughness definition avoids misinterpretation between buyer and supplier.

Core Machined Surface Finish Types

This surface finish guide starts with foundational machining finishes.

As-Machined Finish

- Function: Dimensional accuracy

- Application: Structural, internal parts

- Cost impact: Minimal

Fine Machining / Tool-Optimized Finish

- Reduced tool marks

- Improved surface consistency

- Slightly higher machining cost

Mechanical Surface Finishing Methods

Mechanical processes physically modify surface texture and appearance.

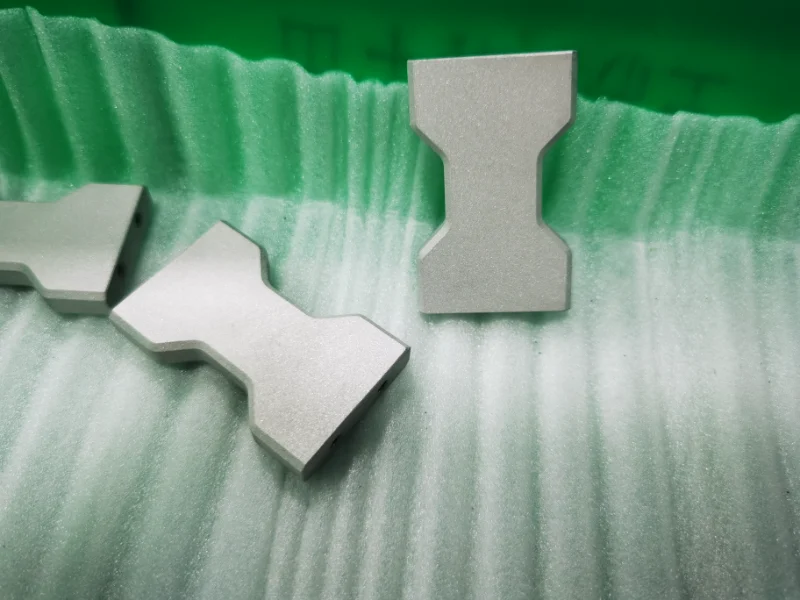

Bead Blasting

- Uniform matte surface

- Removes tool marks

- Widely used for aluminum and stainless steel

Sand Blasting

- More aggressive than bead blasting

- Used for large steel parts or surface cleaning

Brushing

- Directional satin finish

- Common in stainless steel panels and enclosures

Tumbling / Vibratory Finishing

- Edge rounding and burr removal

- Ideal for small batch parts

- Improves handling safety

Chemical and Electrochemical Surface Treatments

A complete surface finish guide must include chemical-based processes.

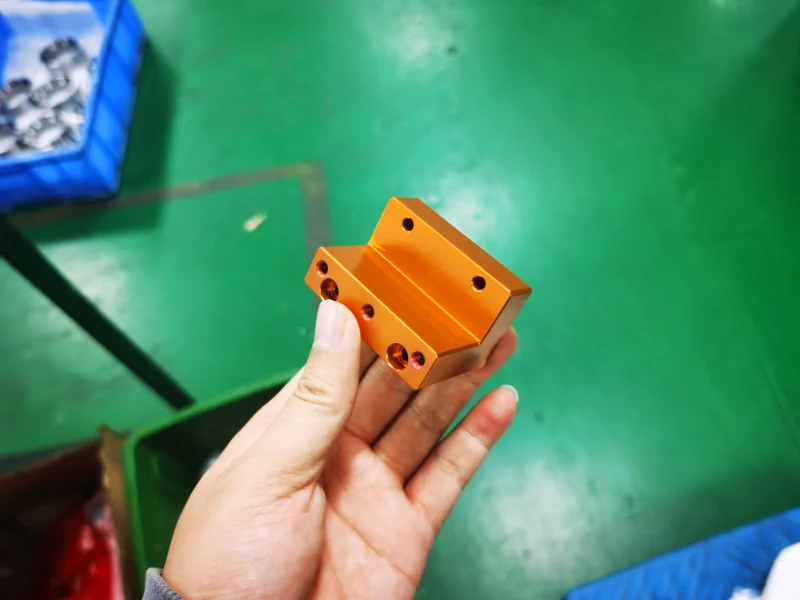

Anodizing (Aluminum)

- Type II: Decorative, corrosion resistance

- Type III (Hard Anodizing): Wear resistance

- Cost: Medium

Chromate Conversion (Alodine)

- Conductive corrosion protection

- Aerospace and electronics applications

- Lower thickness than anodizing

Passivation (Stainless Steel)

- Removes free iron

- Enhances corrosion resistance

- Mandatory for medical and food-grade parts

Coating-Based Surface Finish Options

Coatings add functional layers to machined surfaces.

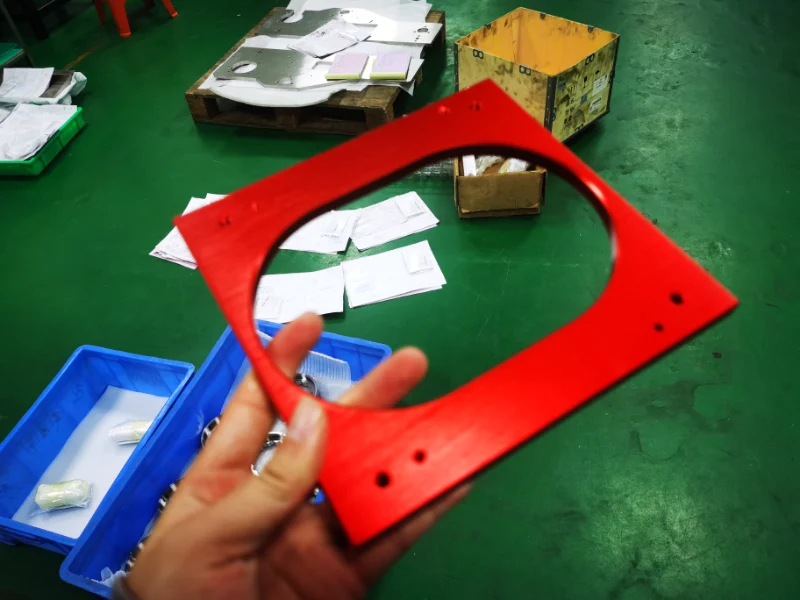

Powder Coating

- Thick, durable protective layer

- Wide color options

- Common in outdoor and industrial parts

Liquid Painting

- Cosmetic branding

- Lower durability than powder coating

- Cost-effective for low volume

PTFE / Teflon Coating

- Low friction

- Chemical resistance

- Used in valves, seals, sliding components

Plating and Metallic Surface Finishes

This surface finish guide includes plating solutions for performance-critical parts.

Electroless Nickel Plating

- Uniform thickness

- Corrosion and wear resistance

- Used in aerospace and oil & gas

Electroplating (Chrome, Zinc, Nickel)

- Improved conductivity or corrosion protection

- Decorative and functional variants

Hard Chrome Plating

- Extreme wear resistance

- Hydraulic and industrial components

Advanced and Specialized Surface Finishes

For high-end applications, this surface finish guide includes advanced treatments.

Electropolishing

- Microscopic smoothing

- Reduces contamination

- Medical and semiconductor industries

Laser Surface Texturing

- Controlled micro-patterns

- Improves lubrication retention

DLC (Diamond-Like Carbon) Coating

- Ultra-low friction

- High hardness

- Automotive and precision mechanisms

Surface Finish Guide for Plastics and Composites

Surface finish selection differs significantly for plastics.

Common finishes include:

- Fine machining

- Vapor polishing (PMMA, PC)

- Light bead blasting

Applications:

- Medical housings

- Optical components

- Chemical-resistant parts

Weldo Machining applies material-specific surface finish strategies for engineering plastics like PEEK, PTFE, and POM.

Surface Finish Cost Comparison Overview

This surface finish guide emphasizes cost control.

Relative cost ranking:

- As-machined

- Tumbling / bead blasting

- Anodizing / passivation

- Powder coating / plating

- Polishing / electropolishing / DLC

Cost drivers include surface area, geometry complexity, and quality standards.

How to Choose the Right Surface Finish

A professional surface finish guide aligns finish choice with real requirements:

- Function first, appearance second

- Avoid over-specification

- Match finish to material behavior

- Consider lifecycle cost, not just unit price

Early supplier involvement reduces both risk and expense.

Why Engineers Choose Weldo Machining for Surface Finishing

Weldo Machining integrates CNC machining and surface finishing into a single quality-controlled workflow. Using this surface finish guide approach, we help customers:

- Select optimal surface treatments

- Reduce unnecessary finishing costs

- Meet ISO, aerospace, and medical standards

- Achieve consistent batch-to-batch quality

From anodizing and plating to advanced coatings, we support both prototypes and production.

Conclusion: A Practical Surface Finish Guide for Real Projects

This surface finish guide provides a complete framework for understanding machining surface treatments, their functions, and costs. Correct surface finish selection improves performance, reliability, and manufacturability. For expert guidance and competitive pricing on CNC machining and surface finishing, contact Weldo Machining to discuss your project requirements.