A professional Sand Blasting guide is essential for engineers, manufacturers, and procurement teams who need consistent surface quality in CNC machined parts. Sand blasting is one of the most widely used surface finishing processes in machining, valued for its ability to clean surfaces, improve appearance, and prepare parts for secondary coatings. This Sand Blasting guide explains the importance of sand blasting in machining, typical sand blasting cost factors, major surface treatment types, and how to choose the right finish for functional and cost-effective production.

Why a Sand Blasting Guide Is Important in Machining

In modern CNC machining, surface condition is just as critical as dimensional accuracy. A structured Sand Blasting guide helps buyers understand how sand blasting influences part performance, coating adhesion, and final product quality.

Sand blasting plays a key role in:

- Removing machining marks and burrs

- Creating uniform surface texture

- Improving paint, anodizing, and coating adhesion

- Enhancing cosmetic consistency

Without a clear Sand Blasting guide, surface treatment choices are often made based on appearance alone, leading to unnecessary cost or performance risks.

The Role of Sand Blasting in CNC Machining Quality

Sand blasting is typically applied after CNC machining and before final coating or assembly. A practical Sand Blasting guide recognizes that blasting is not a replacement for precision machining, but a complementary process.

Key machining-related benefits include:

- Masking minor tool marks without altering dimensions

- Reducing sharp edges for safer handling

- Standardizing surface roughness across batches

At Weldo Machining, sand blasting is integrated into the machining workflow to ensure repeatable surface finish from prototype to production.

How Sand Blasting Works: Process Overview

Any technical Sand Blasting guide should clearly explain the process fundamentals.

Sand blasting works by:

- Accelerating abrasive media using compressed air

- Impacting the media onto the part surface

- Removing contaminants and modifying surface texture

Common blasting media include:

- Aluminum oxide

- Glass beads

- Garnet

- Steel grit

Media selection directly affects surface roughness, appearance, and sand blasting cost.

Sand Blasting Guide to Surface Roughness and Texture

A detailed Sand Blasting guide must connect blasting results with measurable surface finish standards.

- Light sand blasting: Smooth matte texture

- Medium blasting: Uniform industrial finish

- Aggressive blasting: Increased roughness for coating adhesion

Sand blasting does not usually achieve ultra-low Ra values but excels at creating controlled, repeatable textures for downstream processes.

Sand Blasting Cost: What Determines Pricing

Understanding sand blasting cost is a core objective of this Sand Blasting guide.

Primary cost drivers include:

- Part size and surface area

- Material type (aluminum, steel, stainless steel)

- Blasting media type

- Required surface consistency

- Batch quantity

Typical sand blasting cost impact:

- Small CNC parts: Low incremental cost

- Large or complex parts: Moderate cost increase

- High cosmetic standards: Higher labor cost

Early specification of blasting requirements helps avoid unnecessary cost escalation.

Sand Blasting vs Other Surface Finishing Methods

A complete Sand Blasting guide compares blasting with alternative surface treatments.

Sand Blasting vs Bead Blasting

- Sand blasting: More aggressive, higher material removal

- Bead blasting: Smoother, cosmetic-focused

Sand Blasting vs Polishing

- Sand blasting: Texture creation, cost-effective

- Polishing: Low friction, high labor cost

Sand Blasting vs Tumbling

- Sand blasting: External surface treatment

- Tumbling: Edge rounding for small parts

Each method serves different functional and economic goals.

Common Materials Suitable for Sand Blasting

This Sand Blasting guide applies sand blasting across multiple machining materials.

- Aluminum alloys: 6061, 7075

- Carbon steel and alloy steel

- Stainless steel

- Brass and bronze

Material hardness influences media choice, blasting pressure, and final appearance.

Sand Blasting as a Preparation Step for Other Surface Treatments

One of the most valuable roles described in this Sand Blasting guide is surface preparation.

Sand blasting improves:

- Anodizing adhesion

- Powder coating durability

- Painting uniformity

- Plating consistency

For coated CNC parts, sand blasting is often mandatory rather than optional.

Functional Benefits Beyond Appearance

A professional Sand Blasting guide emphasizes function, not just aesthetics.

Functional advantages include:

- Improved coating life

- Reduced risk of peeling or delamination

- Enhanced friction control in mating surfaces

- Better handling safety

These benefits justify sand blasting cost in performance-critical applications.

Typical Applications of Sand Blasting in Machining

This Sand Blasting guide reflects real industrial use cases.

Common applications:

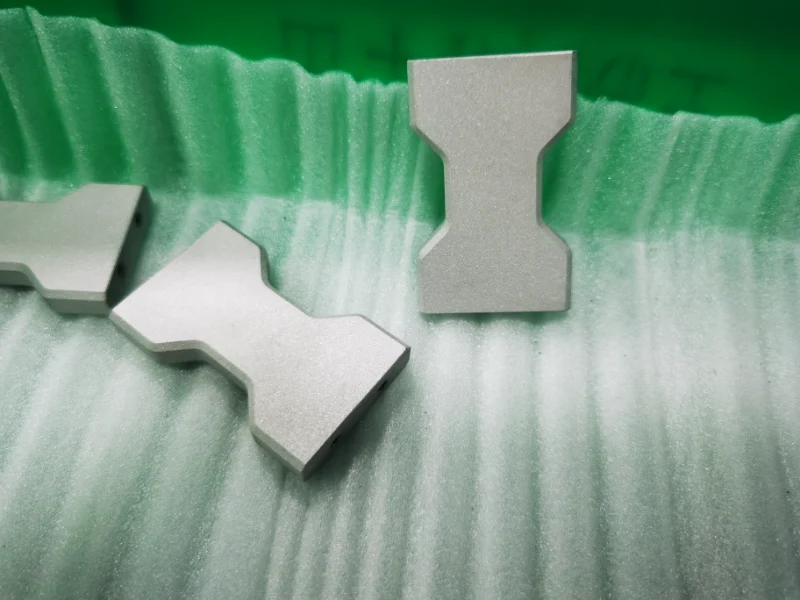

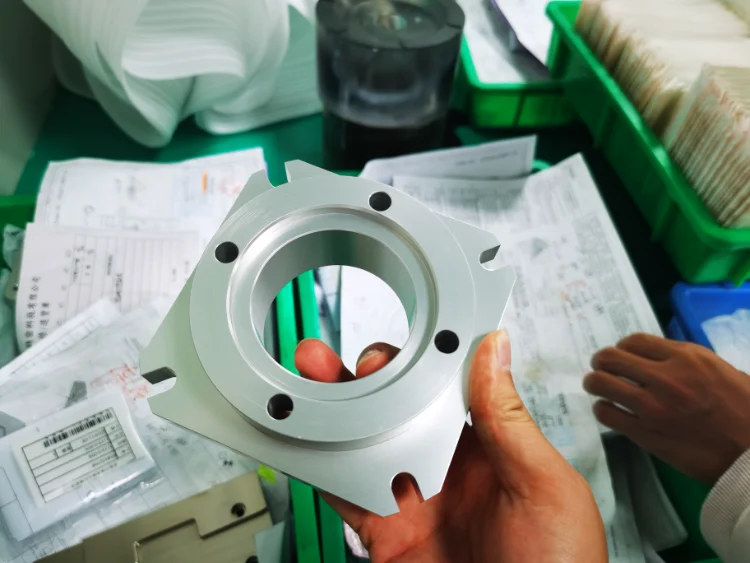

- CNC aluminum housings

- Industrial brackets and frames

- Automotive components

- Aerospace non-critical structures

Sand blasting is widely used where uniform appearance and coating readiness are required.

Choosing the Right Sand Blasting Specification

A practical Sand Blasting guide helps buyers avoid over-specification.

Key questions to answer:

- Is blasting cosmetic or functional?

- What coating will follow blasting?

- What surface roughness is acceptable?

- Is cost or appearance the priority?

Clear answers lead to consistent quality and controlled sand blasting cost.

Common Sand Blasting Mistakes to Avoid

This Sand Blasting guide identifies frequent errors:

- Using overly aggressive media

- Failing to mask precision surfaces

- Ignoring dimensional tolerance impact

- Treating blasting as purely cosmetic

Avoiding these mistakes protects part integrity and reduces rework.

Why Weldo Machining Is a Trusted Sand Blasting Supplier

Weldo Machining applies sand blasting as part of a controlled CNC manufacturing system. Using a proven Sand Blasting guide, our team ensures:

- Correct media selection

- Stable surface finish across batches

- Seamless integration with machining and coating

- Cost-effective surface treatment solutions

From prototypes to volume production, we deliver consistent sand blasting quality.

Conclusion: Using a Sand Blasting Guide to Control Cost and Quality

This Sand Blasting guide demonstrates how sand blasting enhances CNC machining quality, improves coating performance, and delivers cost-effective surface finishing. By understanding sand blasting cost factors, functional benefits, and application limits, manufacturers can make informed decisions. For expert CNC machining and sand blasting solutions, contact Weldo Machining for technical consultation and a competitive quote.