Selecting a professional cnc machining nylon manufacturer is critical for companies sourcing precision nylon components with stable quality and competitive cost. Unlike general CNC suppliers or trading companies, a qualified nylon CNC machining manufacturer provides in-house production, material expertise, and transparent cost control. This page explains how to evaluate a cnc machining nylon manufacturer, covering supplier roles, nylon material applications, machining guidelines, and cost considerations.

CNC Machining Nylon Manufacturer Role in Production and Supply

A true cnc machining nylon manufacturer operates with direct manufacturing capability rather than outsourcing production. This distinction is essential for quality consistency and lead time control.

A professional manufacturer typically offers:

- In-house CNC machining for nylon materials

- Engineering support for material selection

- Stable production from prototype to volume

- Transparent cost structure

- Manufacturer-level quality control

Working directly with a cnc machining nylon manufacturer reduces risk compared with indirect suppliers.

CNC Machining Nylon Manufacturer vs Supplier vs Company

When sourcing nylon CNC parts, buyers often encounter different types of companies.

- Manufacturer: Performs nylon CNC machining internally

- Supplier: May coordinate machining through third parties

- Company / Trading firm: Often has limited process control

For cost efficiency, quality stability, and technical support, partnering with a cnc machining nylon manufacturer is the preferred approach.

Why Companies Choose Nylon for CNC Machining

From a manufacturing and cost perspective, nylon is widely selected when metal performance is unnecessary.

Advantages include:

- Excellent machinability

- Lower cutting forces and tool wear

- Faster CNC cycle times

- Reduced overall machining cost

- Lightweight and corrosion-resistant

These benefits allow a cnc machining nylon manufacturer to deliver high-quality parts at a competitive price.

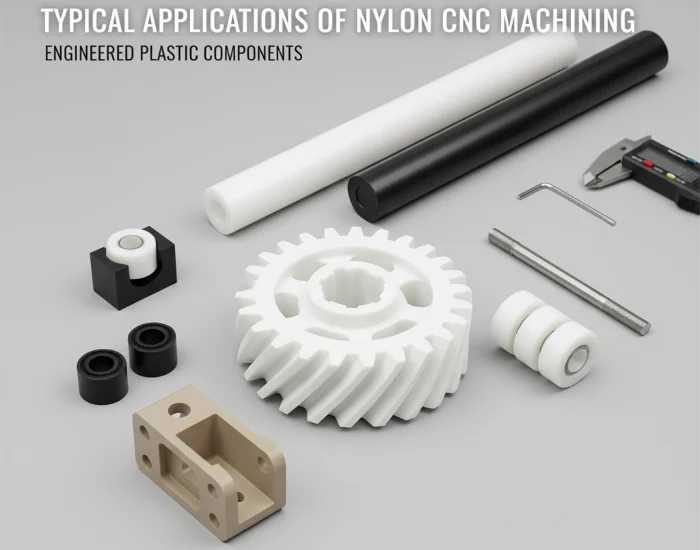

Nylon CNC Machining Guide: Material Types, Applications, and Components

A capable cnc machining nylon manufacturer works with multiple nylon grades to match different application requirements. Each nylon material offers distinct mechanical behavior and cost implications.

PA6 Nylon Applications and CNC Machined Components

PA6 is the most commonly used nylon due to its toughness and cost efficiency.

Typical application industries

- Industrial machinery

- Automation equipment

- Packaging and conveying systems

Common PA6 CNC machined components

- Gears and pinions

- Bushings and sleeves

- Rollers and guide wheels

- Spacers and washers

- Light-load structural parts

PA6 is ideal when impact resistance and cost control are priorities.

PA66 Nylon for Precision CNC Machining Applications

PA66 offers higher stiffness and better wear resistance than PA6.

Typical application industries

- Automation and robotics

- Automotive systems

- Precision mechanical assemblies

Common PA66 CNC machined components

- Precision gears

- Wear pads and sliding blocks

- Bearing cages

- Structural brackets

- High-duty bushings

A cnc machining nylon manufacturer often recommends PA66 for tighter tolerance requirements.

Glass-Filled Nylon for Structural CNC Components

Glass-filled nylon (PA6-GF / PA66-GF) is used for higher load applications.

Typical application industries

- Automotive structures

- Heavy-duty machinery

- Electrical enclosures

Common glass-filled nylon CNC components

- Load-bearing brackets

- Structural housings

- Reinforced mounting parts

- Rigid frames and supports

Glass-filled nylon increases strength but also increases machining complexity and cost.

PA12 Nylon Applications for Dimensional Stability

PA12 is selected for environments requiring low moisture absorption.

Typical application industries

- Medical devices (non-implant)

- Electronics

- Fluid handling systems

Common PA12 CNC machined components

- Precision housings

- Thin-wall structural parts

- Fluid system components

PA12 offers superior dimensional stability in humid conditions.

Modified Nylon for Low-Friction CNC Machined Parts

Oil-filled and modified nylons are designed for wear reduction.

Typical application industries

- Motion control systems

- Conveyor and automation lines

Common modified nylon CNC components

- Self-lubricating gears

- Low-friction bushings

- Sliding rails

- Wear strips

These materials reduce maintenance and extend service life.

Nylon CNC Machining Guide: Manufacturing Process

A professional cnc machining nylon manufacturer follows a controlled machining process to ensure stability and precision.

Typical steps include:

- Material conditioning to control moisture

- CNC milling and turning with optimized parameters

- Low-stress fixturing to avoid deformation

- Controlled cutting speeds and feeds

- Final dimensional inspection

This approach ensures repeatable quality across batches.

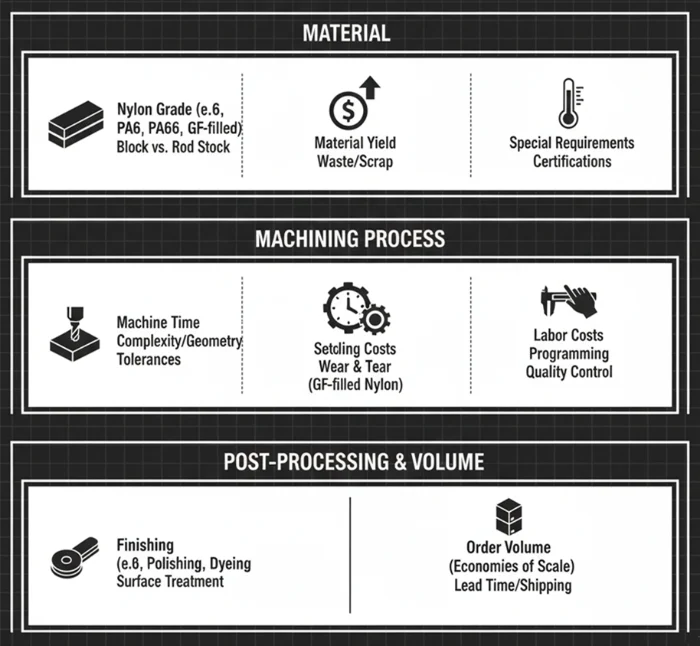

Cost Structure at a CNC Machining Nylon Manufacturer

Understanding cost structure helps buyers compare manufacturers effectively.

Key cost drivers include:

- Nylon material grade

- Part geometry and machining time

- Tolerance and surface finish requirements

- Scrap and rework risk

- Order quantity

A transparent cnc machining nylon manufacturer clearly explains how these factors influence pricing.

Typical CNC Machining Nylon Cost Range (USD)

For reference only, manufacturer-level pricing typically falls within:

- Simple nylon CNC parts: USD 25–80 / part

- Medium complexity parts: USD 40–120 / part

- High-precision nylon components: USD 80–180 / part

Higher volumes significantly reduce unit cost.

Quality Control at a CNC Machining Nylon Manufacturer

Quality assurance is critical for nylon CNC machining.

Standard controls include:

- Dimensional inspection

- Surface finish verification

- Material traceability

- Process consistency monitoring

A reputable cnc machining nylon manufacturer integrates quality checks throughout production.

Prototype and Production Support from a Nylon CNC Manufacturer

An experienced cnc machining nylon manufacturer supports:

- Rapid prototyping

- Design validation

- Low-volume production

- Stable batch manufacturing

This capability reduces development risk and improves time-to-market.

Why Choose Weldo Machining as Your CNC Machining Nylon Manufacturer

Weldo Machining operates as a professional cnc machining nylon manufacturer, not a trading supplier. We specialize in nylon CNC machining for global customers requiring precision, consistency, and cost control.

Our strengths include:

- Expertise in PA6, PA66, and modified nylon

- Dedicated CNC equipment for engineering plastics

- Cost-optimized manufacturing strategies

- Stable quality and responsive engineering support

Conclusion: Choosing the Right CNC Machining Nylon Manufacturer

Selecting the right cnc machining nylon manufacturer directly impacts product performance, lead time, and total manufacturing cost. By working with a manufacturer that understands nylon material behavior, application requirements, and machining economics, companies achieve reliable and cost-effective results.

Contact Weldo Machining to discuss your nylon CNC machining project and receive a manufacturer-level quotation.