CNC machining tools are the core execution elements that directly determine machining accuracy, surface finish, tool life, and production efficiency. For a qualified CNC machining service provider, precision machining tools are not interchangeable consumables—they are carefully selected, calibrated, and managed assets that ensure consistent quality for customer parts.

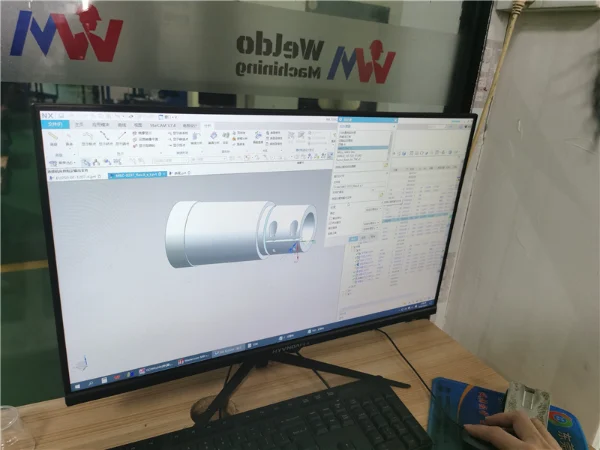

At Weldo Machining, machining tools are integrated into every stage of our machining workflow, from programming and setup to final inspection.

What CNC Machining Tools Mean for a Machining Service Provider

For a professional service provider, machining tools refer to all cutting, forming, and probing tools used on CNC machines to remove material and verify accuracy.

Unlike hobby or low-volume shops, a qualified CNC machining service provider focuses on:

- Tool consistency across batches

- Predictable tool wear behavior

- Compatibility with multiple materials

- Precision repeatability

Effective management of precision machining tools is essential for stable production and customer trust.

Main Types of CNC Machining Tools in a Service Shop

A complete machining service operation relies on a structured set of machining tools.

CNC Cutting Tools

CNC cutting tools perform material removal and shape creation.

Common precision machining tools include:

- End mills (flat, ball nose, corner radius)

- Drills and reamers

- Boring tools

- Thread mills and taps

These CNC machining tools are selected based on material type, cutting strategy, and tolerance requirements.

Turning and Threading Tools

For CNC turning operations, specialized machining tools are required.

- External and internal turning tools

- Grooving tools

- Threading inserts

Precision turning CNC machining tools are critical for concentricity and surface quality.

Tool Holders and Tooling Systems

Precision machining tools are only as accurate as the holders that support them.

Professional CNC machining service providers use:

- Hydraulic tool holders

- Shrink-fit holders

- Precision collet systems

High-quality holders improve tool rigidity and reduce runout, directly affecting machining accuracy.

CNC Machining Tools Selection Principles

Correct selection of CNC machining tools is a key differentiator between basic and professional machining services.

Material-Driven Tool Selection

Different materials require different precision machining tools:

- Aluminum favors sharp, high-polish tools

- Stainless steel requires wear-resistant coatings

- Titanium demands heat-resistant tool geometry

- Plastics require low-friction cutting edges

Using the wrong precision machining tools leads to poor finish, dimensional drift, and tool failure.

Geometry and Tolerance Considerations

Part geometry and tolerance dictate CNC machining tools selection:

- Deep cavities require long-reach tools with vibration control

- Tight tolerances require stable tool geometry

- Complex surfaces benefit from multi-flute ball end mills

Professional service providers match precision machining tools precisely to design intent.

Proper Use Methods for CNC Machining Tools

Even the best CNC machining tools fail without correct usage methods.

Cutting Parameters and Tool Life

Optimized spindle speed, feed rate, and depth of cut extend precision machining tools life while maintaining accuracy.

Tool Path Optimization

Advanced CAM strategies ensure:

- Consistent chip load

- Reduced tool engagement shock

- Stable cutting forces

These practices protect CNC machining tools and ensure repeatable results.

Precision Calibration of CNC Machining Tools

Calibration is essential to extract full performance from precision machining tools.

Tool Length and Diameter Calibration

Professional CNC machining service providers use:

- Preset tool measuring systems

- In-machine probing

Accurate calibration ensures tool offsets match real cutting conditions.

Runout and Alignment Control

Even minimal runout can compromise precision machining.

- Runout must be controlled within microns

- Tool holders are inspected regularly

- Worn CNC machining tools are removed proactively

This discipline is critical for high-tolerance parts.

Common CNC Machining Tools Problems and Solutions

Over time, CNC machining tools encounter predictable issues.

Typical Problems

- Premature tool wear

- Tool chipping or breakage

- Dimensional inconsistency

- Poor surface finish

Practical Solutions

- Adjust cutting parameters

- Upgrade tool coating or geometry

- Improve tool holder rigidity

- Implement tool life monitoring

Experienced service providers solve these issues before they affect customer deliveries.

CNC Machining Tools and Machining Accuracy

Machining accuracy depends directly on CNC machining tools condition and control.

- Worn tools cause tolerance drift

- Inconsistent tool replacement affects repeatability

- Poor calibration invalidates CAM programming

Qualified CNC machining service providers maintain strict control over precision machining tools to protect accuracy.

Why CNC Machining Tools Management Defines a Qualified Service Provider

Customers often evaluate machining capability by machine brand—but long-term quality depends more on precision machining tools management.

A qualified CNC machining service provider demonstrates:

- Structured tool selection standards

- Regular calibration and inspection

- Documented tool life control

- Continuous tooling optimization

These practices separate professional machining services from low-cost, unstable suppliers.

Why Choose Weldo Machining for CNC Machining Services

At Weldo Machining, our cnc machining tools are selected, calibrated, and managed to support high-precision CNC machining services. We invest in advanced cutting tools, precision holders, and calibration systems to ensure stable accuracy across all production volumes.

From prototype development to production machining, Weldo Machining delivers consistent results backed by disciplined tool management. Contact us today to discuss your project requirements and receive a competitive quotation.