A rapid CNC machining manufacturer plays a critical role in modern product development by delivering fast, accurate, and scalable machined parts. As industries accelerate innovation cycles, the demand for a reliable CNC machining manufacturer continues to grow, especially for prototyping, bridge production, and short-run manufacturing.This article explains the definition, core machining processes, efficiency strategies, cost considerations, and application scenarios that define a professional CNC machining manufacturer.

What Is a Rapid CNC Machining Manufacturer?

A rapid CNC machining manufacturer specializes in producing CNC machined parts with extremely short lead times while maintaining tight tolerances and consistent quality. Unlike conventional machining suppliers focused on long production cycles, a CNC machining manufacturer emphasizes speed, flexibility, and responsiveness.

Key characteristics of a rapid CNC manufacturer include:

- Short lead times (often days instead of weeks)

- High-precision CNC equipment

- Streamlined quoting and programming workflows

- Strong prototyping and low-volume production capability

A qualified CNC machining manufacturer supports engineers and product teams from early design validation to full production readiness.

Core Advantages of a Rapid CNC Machining Manufacturer

Working with a rapid CNC machining manufacturer provides significant operational advantages:

- Faster product development cycles

- Reduced time-to-market

- Flexible design iterations

- Lower risk before mass production

By leveraging advanced CNC technology, a CNC machining manufacturer enables quick design changes without expensive tooling investments.

CNC Machining Processes Used by a Rapid CNC Machining Manufacturer

To achieve speed without sacrificing quality, a CNC machining manufacturer integrates multiple CNC processes into a single production workflow.

CNC Milling for Rapid Machining

CNC milling is the backbone of a CNC machining manufacturer’s operation.

- Ideal for complex geometries and prismatic parts

- Supports 3-axis, 4-axis, and 5-axis machining

- Adaptive toolpaths reduce cycle time

High-speed milling strategies allow a rapid CNC machining manufacturer to remove material efficiently while maintaining dimensional accuracy.

CNC Turning for Fast Cylindrical Parts

CNC turning enables a rapid CNC machining manufacturer to quickly produce round or rotational components.

- Shafts, bushings, and threaded parts

- High concentricity and surface consistency

- Efficient for both prototypes and batch production

Turning centers with live tooling further enhance production speed.

Drilling, Tapping, and Thread Machining

Hole-making operations are essential for a CNC machining manufacturer.

- Fast drilling cycles with optimized feeds and speeds

- Rigid tapping for accurate internal threads

- Supports metric, UNC, and UNF thread standards

Efficient drilling strategies reduce tool wear and processing time.

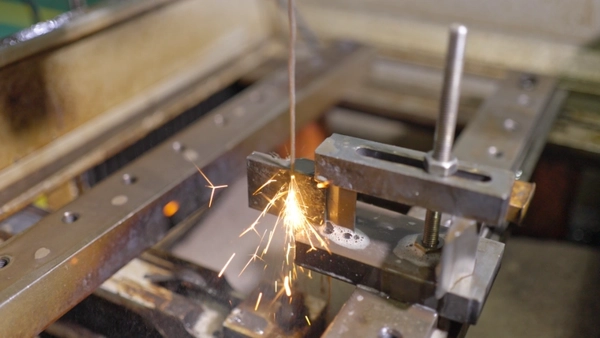

EDM Machining for Complex Features

When conventional cutting is inefficient, a rapid CNC machining manufacturer may apply EDM machining.

- Wire EDM for intricate profiles and sharp internal corners

- Sink EDM for deep cavities and hardened materials

- No cutting force, minimizing part distortion

EDM complements traditional CNC processes in rapid manufacturing environments.

Materials Commonly Supported by a Rapid CNC Machining Manufacturer

A professional CNC machining manufacturer works with a wide range of metals and engineering plastics.

Common Metal Materials

- Aluminum alloys (6061, 7075, 2024)

- Stainless steel (304, 316, 17-4PH)

- Carbon steel and alloy steel

- Brass and copper alloys

- Titanium alloys

Engineering Plastics

- ABS, Nylon, POM (Delrin)

- PTFE, PEEK

- Polycarbonate (PC)

Material availability and machinability directly influence turnaround time for a CNC machining manufacturer.

Speed Optimization Strategies in Rapid CNC Machining

A rapid CNC machining manufacturer achieves short lead times through systematic optimization.

Key Speed-Focused Practices

- DFM analysis: Simplifies geometry before machining

- Standardized fixturing: Reduces setup time

- CAM automation: Accelerates toolpath generation

- In-house finishing: Avoids outsourcing delays

These practices allow a rapid CNC machining manufacturer to deliver parts faster without compromising quality.

Cost Considerations When Choosing a Rapid CNC Machining Manufacturer

Speed does not necessarily mean higher cost when working with an experienced CNC machining manufacturer.

Primary Cost Drivers

- Material type and size

- Machining time and complexity

- Tolerance requirements

- Surface finish specifications

- Order quantity

Early collaboration with a CNC machining manufacturer helps balance speed, cost, and performance.

Applications Served by a Rapid CNC Machining Manufacturer

A rapid CNC machining manufacturer supports a wide range of industries:

- Product development and R&D

- Aerospace and defense prototyping

- Medical device validation

- Automotive functional testing

- Industrial equipment components

- Consumer electronics enclosures

In each case, rapid iteration and reliable precision are essential.

Quality Control in Rapid CNC Machining Manufacturing

Despite compressed timelines, a professional rapid CNC machining manufacturer maintains strict quality standards.

Quality measures typically include:

- In-process dimensional checks

- Final inspection using CMM equipment

- Material certification and traceability

- Surface finish and tolerance verification

Quality systems ensure rapid delivery without sacrificing part reliability.

Rapid CNC Machining vs. Other Rapid Manufacturing Methods

Compared with 3D printing or soft tooling, a rapid CNC machining manufacturer offers:

- Superior material strength

- Tighter tolerances

- Better surface finish

- Production-ready parts

For functional testing and end-use components, CNC machining remains the preferred rapid manufacturing solution.

Conclusion

A capable rapid CNC machining manufacturer enables fast, accurate, and flexible production for prototypes and short-run parts. By combining efficient CNC milling, turning, and EDM processes, rapid CNC machining supports accelerated product development.

For reliable rapid CNC machining support, Weldo Machining offers fast response, technical expertise, and competitive pricing. Contact Weldo Machining to request more information or a tailored CNC machining quote.