If you build products at scale, cnc machining for oems links your drawings to consistent, repeatable shipments—so your line builds on time.

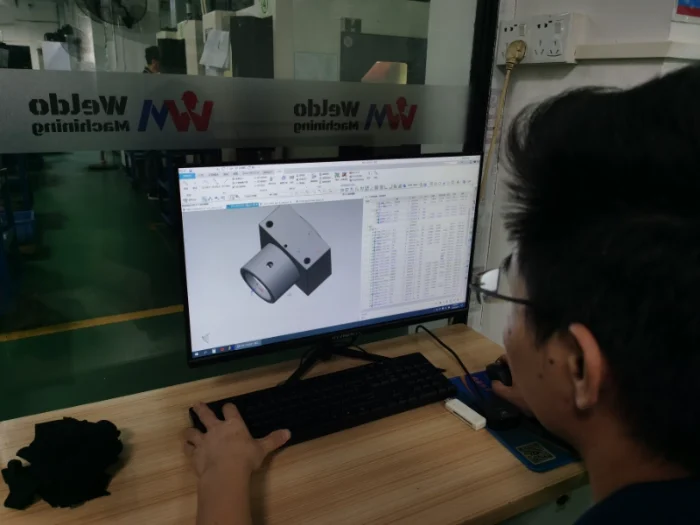

Finding an experienced manufacturing partner can help you with design and structural drawings, optimize design parameters and details, assess manufacturability and cost, and ultimately ensure your parts perfectly meet your needs during production and quality control. The following is an introduction to OEM manufacturing.

What cnc machining for oems Really Means for Buyers

For procurement and engineering teams, oems cnc machining is not “make a part,” and it is not a one-off job. It is a controlled manufacturing workflow that protects fit, function, and delivery. A capable cnc machining for oems partner aligns three things early, because cnc machining oems is won at launch: technical risk, quality evidence, and supply continuity.

What to expect from cnc machining for oems:

- Long-term part ownership (revisions, ECOs, sustaining support)

- Documented inspection and traceability for OEM builds

- Clear expectations for OEM components performance in assembly

How cnc machining for oems Moves Through a Production-Ready Launch

Step 1: RFQ inputs that speed up precision decisions

Fast, accurate quoting depends on complete inputs for cnc machining for oems, and cnc machining for oems quoting discipline protects schedules. Provide:

- STEP + PDF drawing with GD&T and datum scheme

- Material grade, approved alternates, and heat treatment

- Inspection plan for OEM CNC parts and acceptance criteria

This is where precision CNC machining is defined inside custom machining services: by tolerances, datums, and inspection points that can be repeated.

Step 2: DFM that reduces cost without weakening quality

Best-in-class cnc machining for oems includes DFM feedback, and buyers should expect actionable suggestions before programs are locked. Typical DFM wins for precision CNC machining:

- Standardize corner radii to match common tools

- Avoid over-tolerancing on non-functional surfaces

- Add inspection-friendly datums on OEM CNC parts

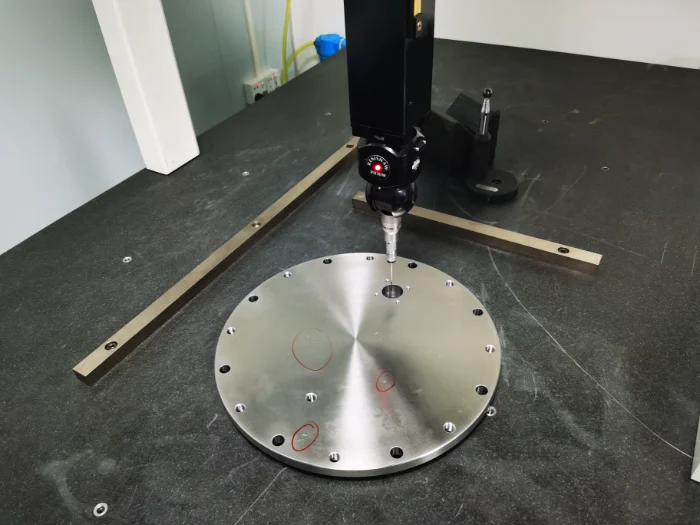

Step 3: Pilot lots that prove your process, not just your part

A pilot run in cnc machining for oems validates setup repeatability, gaging, and handling, so scale is predictable. Ask for:

- First Article Inspection (FAI) on OEM CNC parts

- CMM reports for geometric features

- Sampling rules for critical dimensions

Process Selection in cnc machining for oems: Milling, Turning, Multi-Axis

Most cnc machining for oems programs mix operations, and custom machining services planning should minimize handoffs. The right process choice improves consistency for OEM CNC parts and reduces lead-time risk.

CNC milling for prismatic OEM components

CNC milling supports pockets, slots, contours, and complex faces. In precision CNC machining, milling controls positional tolerances on OEM CNC parts.

CNC turning for rotational features

CNC turning is ideal for shafts, bores, rings, and concentric parts. When assemblies depend on runout or coaxiality, turning strengthens precision CNC machining stability for OEM CNC parts.

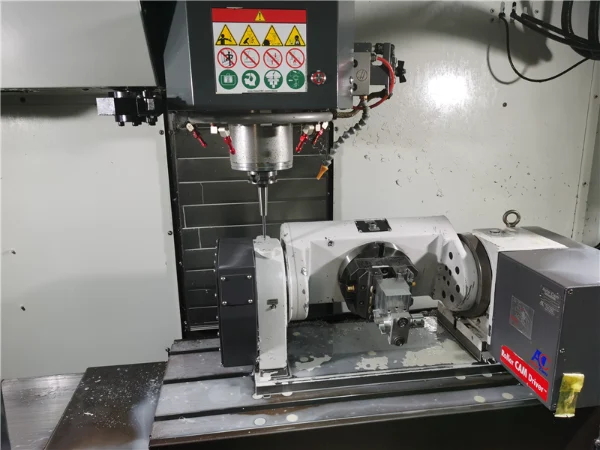

4-axis and 5-axis machining for consolidation

In cnc machining for oems, multi-axis machining can remove extra setups, reduce re-clamping error, and improve throughput. Consolidation often improves quality on OEM CNC parts while lowering total cost.

Materials That Perform Well in cnc machining for oems

Material choice affects cycle time, tool wear, finishing, and inspection strategy in OEM CNC manufacturing

. Repeatable supply depends on stable materials, especially when platforms standardize inputs for OEM CNC parts.

Common metals for precision CNC machining:

- Aluminum 6061/7075 for lightweight strength

- Stainless 303/304/316 for corrosion resistance

- Brass/copper for conductive features

Common plastics for production components include Acetal, Nylon, PTFE, and PEEK.

A strong supplier will suggest alternates that preserve function while improving machinability—an important lever in cnc machining for oems and custom machining services.

Tolerances in cnc machining for oems and Precision CNC Machining

Tight tolerances matter in OEM CNC manufacturing , but only when they protect function. They must also be measurable. Over-tolerancing increases inspection time, raises scrap risk, and slows custom machining services throughput.

Ways to keep precision CNC machining scalable:

- Identify critical-to-function dimensions on OEM CNC parts

- Relax non-critical tolerances to reduce cycle time

- Use clear datums and avoid ambiguous callouts

- Require capability evidence on the few features that matter

A practical OEM rule in cnc machining for oems: spend tolerance only where it buys assembly reliability, sealing performance, or motion control in OEM CNC parts.

Quality Controls in cnc machining for oems and Custom Machining Services

OEM buyers evaluate custom machining services based on evidence, not promises. In OEM CNC manufacturing , quality is a system that can be audited and repeated, so suppliers must document controls.

Typical deliverables for OEM programs:

- FAI packages for OEM CNC parts

- CMM inspection reports on key GD&T

- Material certificates and lot traceability

- Calibration records for measurement tools

When custom machining services includes documented controls, precision CNC machining results become predictable across lots of OEM CNC parts.

Finishing in cnc machining for oems for OEM CNC Parts

Many OEM components require finishing or light assembly in cnc machining for oems. The finishing plan should be integrated so critical features remain in tolerance.

Common finishes used in cnc machining for oems:

- Anodizing for aluminum

- Passivation for stainless

- Plating for wear or conductivity

Common secondary operations inside custom machining services:

- Deburring and edge conditioning

- Threading, helicoils, and inserts

- Laser marking for traceability on OEM CNC parts

The best results occur when finishing is planned with precision CNC machining allowances, masking strategy, and post-finish inspection on OEM CNC parts.

Cost and Lead-Time Levers in cnc machining for oems

Pricing for cnc machining for oems is driven by more than material cost. Pricing should reflect process risk.

Primary cost drivers:

- Number of setups and fixture complexity

- Cycle time and tool life in precision CNC machining

- Inspection time for high-risk OEM CNC parts

Practical cost reduction that protects quality:

- Use DFM to remove hard-to-machine features

- Consolidate operations (multi-axis or mill-turn)

Supply Continuity: What Mature cnc machining for oems Looks Like

Stable cnc machining for oems requires planning discipline, and programs should plan for variability. A dependable custom machining services partner supports long-term builds with predictable lead times and controlled change management.

Stability practices that matter:

- Forecast sharing and blanket orders

- Safety stock or Kanban for repeat OEM CNC parts

- Revision control and ECO response times

When supply planning is integrated with custom machining services, OEM teams spend less time firefighting and more time improving product performance through precision CNC machining.

Quick Answers for cnc machining for oems Buyers

How do I qualify a supplier for cnc machining for oems?

Review sample inspection reports, confirm measurement capability, and check revision control. Ask how custom machining services maintains repeatability in cnc machining for oems for OEM CNC parts under production scheduling.

What should I send to get a reliable quote?

For cnc machining for oems, send STEP + PDF, volume expectations, material/finish specs, and any inspection templates. Clear inputs improve precision CNC machining routing and reduce quoting gaps for OEM CNC parts.

Can one supplier support prototype through production?

Yes—if their custom machining services includes pilot lots, controlled inspection, and capacity planning. That continuity reduces transfer risk and keeps OEM CNC parts consistent.

How do you keep quality stable across batches?

Use controlled setups, documented inspection points, and traceable materials. In precision CNC machining, stable datums and repeatable gaging are the fastest path to consistent OEM CNC parts.

What’s the most common reason OEM programs slip?

Ambiguous drawings and late changes. In cnc machining for oems, clear GD&T plus disciplined ECO handling protects lead time and stabilizes custom machining services.

Work With Weldo Machining on CNC Machining for OEMs

If you need OEM CNC manufacturing that remains consistent from first article to sustained production, and you want a partner built for cnc machining for oems, Weldo Machining supports OEM programs with precision CNC machining, dependable OEM CNC parts, and scalable custom machining services. Contact Weldo Machining for more information, technical feedback, and a fast quotation for your next cnc machining oems project.