Fillet refers to the process of rounding off the sharp edges of parts, primarily used to improve their strength, reduce stress concentration, and enhance the aesthetics of the component. This article will explore the types of Edge curve, their common radii, machining methods, and how they impact the material choice and processing accuracy. Additionally, we will provide valuable insights into the fillet’s role in CNC machining.

Types of Fillets

Corner round come in several varieties, depending on their application and design needs:

Concave Fillet (Inner edge curve)

- Usage: Typically used for internal transitions or connections in parts where the curve is oriented towards the inside of the part.

Convex Fillet (Outer edge curve)

- Usage: More commonly used for external connections or load-bearing components, as it provides more strength and durability at the transition points.

Uniform Fillet

- Usage: Has a consistent radius throughout, suitable for standard parts where uniformity is required.

Variable Fillet

- Usage: The radius gradually changes along the curve, often used for complex parts or in areas with high stress. It helps in gradually distributing stress and improving part strength.

Fillet Radius

The Corner round is a crucial parameter in determining the size and appearance of the fillet. It directly influences the part’s strength, machining complexity, and overall look.

Common Fillet Radii

- R0.5 or R1: Used for micro-sized parts or thin-walled designs. Common in precision machinery, micro-components, small electronic products, and parts that require higher assembly precision and reduced part breakage.

- R2 or R3: Suitable for medium-sized parts or regular mechanical components. This radius is commonly used in everyday mechanical parts, automotive components, structural pieces, etc.

- R5 or R10: Applied to parts that bear high pressure or stress. Typically used in automotive components, large machinery, or structural parts to enhance strength and longevity.

- R20 or R30: Used for large-sized components or high-strength parts such as pressure vessels and pipe interfaces. These larger radii help to distribute stress and reduce material fatigue.

Fillet Machining Methods

There are various machining methods for edge curves, and the choice depends on the part size, material, and machining requirements.

CNC Milling

- Suitable For: Most metal, plastic, and composite parts, particularly for high-precision fillet designs.

- Common Range: CNC milling can achieve edge curve radii from R0.5 to R20 and even larger, depending on the tool radius.

Grinding

- Suitable For: Hard metals (e.g., stainless steel, titanium alloys) and high-precision parts.

- Common Range: Ideal for larger edge curve radii (such as R5, R10, R20) and provides high-precision surface finishes.

Injection Molding

- Suitable For: Plastic parts, especially those produced in large quantities.

- Common Range: Common fillet radii for injection molding are R1, R2, and the radius can be directly formed in the mold when designed accordingly.

Laser Cutting

- Suitable For: Thin sheet materials and lightweight plastics.

- Common Range: Generally used for smaller fillet sizes (e.g., R1, R2) and is highly efficient for mass production.

Fillet Tolerance

Corner round tolerance directly affects the part’s fit, function, and overall machining quality. Tolerance requirements typically fall into the following categories:

- Standard Tolerance: Typically ±0.1mm, suitable for regular mechanical parts and structural components.

- High Precision Tolerance: ±0.05mm, ideal for precision machinery, instrument parts, and high-accuracy connections such as drive systems and gears.

- Ultra-High Precision Tolerance: ±0.01mm, typically used for aerospace, precision engineering, and specialized equipment, such as aerospace components and precision molds.

Fillet and Material Considerations

Corner round design and the choice of material are closely linked. The hardness, toughness, and machining process of the material influence the choice of Corner round radius.

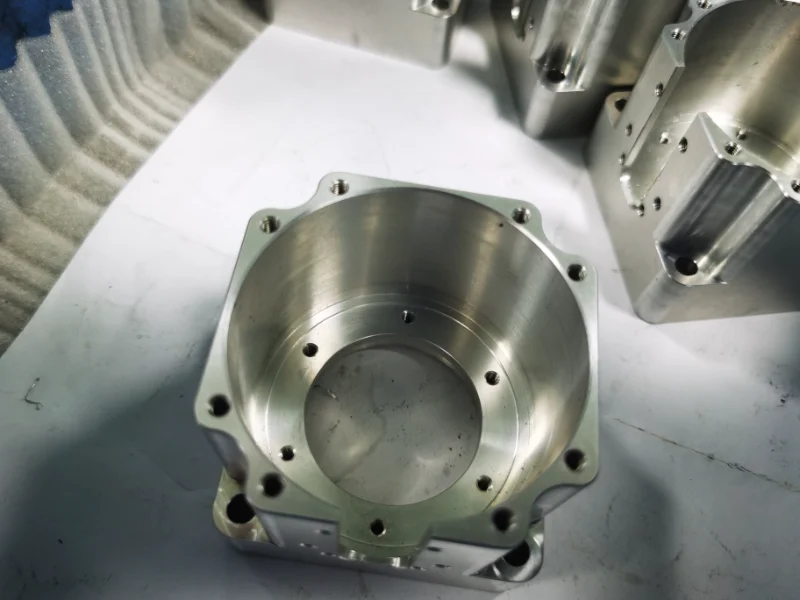

Aluminum Alloys and Steel

- Machining Methods: CNC milling and grinding are commonly used for aluminum and steel, with Corner round radii typically ranging from R2 to R3, suitable for medium-sized parts.

Stainless Steel and Titanium Alloys

- Machining Methods: Requires precise CNC machining or grinding, ideal for larger Corner round radii such as R5 or R10, which help improve strength and durability.

Plastics

- Machining Methods: Commonly machined using injection molding or CNC machining, with Corner round radii generally being R1, R2, often used for housings, connectors, and other applications.

Composites

- Machining Methods: Typically CNC machined, composite materials often require larger Corner round radii, such as R5 or R10, to enhance tensile strength and fatigue resistance.

Conclusion

Edge curve design plays a crucial role in CNC machining. By selecting the appropriate Corner round radius, shape, and machining method, manufacturers can improve part strength, reduce stress concentration, and enhance overall durability. Whether you’re working with metals, plastics, or composites, proper Corner round design ensures that parts are both functional and efficient.

If you are seeking high-quality, precise CNC machining for your projects, contact Weldo Machining for more information and a customized quote today. Our team of experts is ready to assist you with all your machining needs.