In the manufacturing industry, 3 axis CNC machining cost is a key factor influencing production decisions and project budgets. As market competition intensifies and demand for personalized, high-precision parts grows, understanding and controlling these costs has become critical. This article breaks down the components of 3 axis CNC machining costs and explores how businesses can optimize and reduce them to maximize cost-efficiency while maintaining machining quality.

Components of 3 Axis CNC Machining Cost

Raw Material Cost

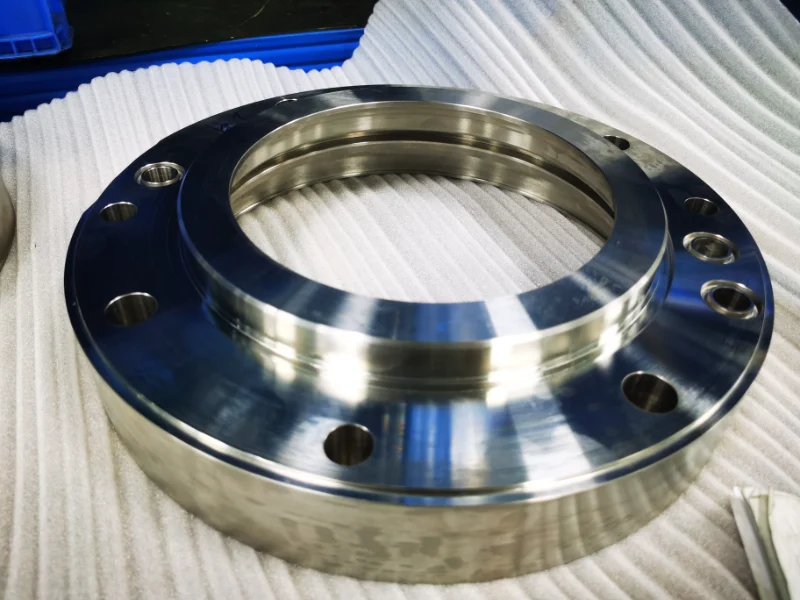

Raw materials are a significant portion of 3 axis CNC machining cost. Different materials have varying prices that directly affect cost. For example, aluminum is cheaper than steel, but harder materials like titanium and hardened steel require more complex processing and equipment, raising costs.

Machining Time & Equipment Use

Machining time directly impacts equipment and labor costs. High-precision machining usually requires more time, leading to increased energy consumption and longer machine downtimes, reducing efficiency. Complex parts may require multiple cutting passes, further adding to the time and cost.

Why Use 3 Axis CNC Machining?

High Precision

3 axis CNC machines offer high precision, with common tolerances reaching ±0.01mm, and even tighter tolerances of 0.001-0.005mm for high-end machines. This makes them ideal for precision-critical industries such as aerospace and medical devices.

Simple Process & Lower Equipment Costs

Compared to multi-axis machines, 3-axis machines are simpler to operate and maintain, making them more cost-effective for businesses with simpler machining needs or limited budgets.

Fast Machining Speed

3-axis CNC machines are efficient, allowing for fast milling, drilling, and other machining tasks, meeting the demands of short production cycles and improving overall productivity.

Machining Part Complexity

Part Design Complexity

The complexity of a part’s design significantly impacts machining cost. Complex shapes, fine details, and multi-hole structures increase machining time and may require higher-precision tools, adding to the overall cost. Simplifying designs and optimizing machining paths can help reduce costs.

Multiple Machining Steps & Precision Requirements

High-precision parts may need multiple machining steps, each contributing to additional costs. For example, roughing and finishing stages require more time and equipment. Precision demands also require high-quality tools, increasing costs. Designing efficient machining processes can minimize these costs.

Machine Types

High-End vs. Standard CNC Machines

High-end CNC machines provide greater precision and speed but come with higher acquisition, maintenance, and operational costs. These machines often include advanced automation features, which boost efficiency but increase initial investment and ongoing costs. In contrast, standard machines have lower acquisition costs but may have higher operational costs, especially under heavy loads.

Automation vs. Manual Intervention

Automation reduces manual labor and improves precision, but automated machines have higher initial costs and maintenance needs. While reducing human error, automated systems may require more skilled operators and additional training.

Tooling Costs

Tool Material & Cost

The type of tool used impacts 3 axis CNC machining cost. Carbide tools, although more expensive, offer longer life and better cutting performance, making them ideal for harder materials. High-speed steel tools are cheaper but have lower performance, suitable for softer materials.

Tool Wear & Replacement

Tool wear directly affects precision and efficiency, making regular tool replacement necessary. Worn tools reduce part quality and may cause excessive machine load, shortening equipment lifespan. Efficient tool management can help lower production costs.

Production Batch

Small-Batch Production Costs

Small batches typically have higher per-unit machining costs due to setup and adjustment times. However, they offer more flexibility compared to large batches. Managing batch size effectively can help reduce these costs.

Batch Effects & Cost Savings

Larger production batches distribute setup and adjustment costs across more parts, lowering the per-unit cost. Increased batch size also improves equipment utilization, reducing overall production costs. However, equipment stability and precision must be maintained to avoid quality issues.

How to Lower 3 Axis CNC Machining Costs

Optimizing Design & Material Selection

Simplifying designs and choosing cost-effective materials can reduce machining costs. Easy-to-machine materials and efficient design can reduce machining time and minimize tool wear, cutting costs significantly.

Process Optimization & Smart Management

Optimizing machining paths and avoiding unnecessary steps can also reduce costs. Using digital management and real-time monitoring can improve efficiency, reduce waste, and control 3 axis CNC machining costs.

Conclusion

The structure of 3 axis CNC machining cost is complex, involving raw materials, equipment, machining time, and tool replacement. To manage costs effectively while ensuring quality, businesses must consider design optimization, process improvements, equipment selection, and production batch size. By optimizing these factors, companies can reduce 3 axis CNC machining costs and improve profitability.

If you want know more details or get an instant quote,please feel free to contact with us.