“CNC milling type” is not a single term—it is a multi-dimensional classification system that includes machine capability (axis count), machine structure, feature-based milling methods, toolpath/cutting strategies, and material- or condition-driven approaches. Understanding CNC milling types helps reduce setups and datum transfers, improve process stability, and make cost and lead time more predictable while meeting geometry, tolerance, and surface requirements.

Manual (Conventional) Milling vs CNC Milling: Capability and Stability

Milling is commonly divided into manual (conventional) milling and CNC milling. Both can produce basic milled features, but they differ significantly in repeatability, complexity handling, and tolerance stability.

Manual/Conventional Milling

Manual milling relies on operator skill to control travel, feed, and dimensional adjustments. It suits simple geometries, small quantities, and repair/rework tasks. It is flexible to modify, but consistency depends heavily on operator technique and shop conditions.

- Typical uses: basic facing, slotting, chamfering, small quantity work, rework/repair, quick trial cuts

- Main limitations: limited capability for complex contours and tight positional tolerances; higher variation risk for tight tolerances and cosmetic requirements

- Common issues and fixes:

- Large dimensional variation: use a “leave stock—finish cut—re-check” rhythm for critical dimensions; keep critical features within one setup and datum whenever possible; add simple stops or locating aids to improve repeatability.

- Rough tool marks / surface tearing: reduce tool stick-out, keep tools sharp, improve clamping rigidity; on visible surfaces, use continuous single-direction passes to avoid uneven texture from frequent stops.

- Inconsistent burrs/edges: specify measurable edge break and deburring requirements (e.g., a standard chamfer range) to reduce interpretation differences.

CNC Milling

CNC milling uses programmed toolpaths, cutting parameters, and operation order, making it suitable for multi-feature, multi-face parts, tight tolerances, and consistent production. Its key strengths are repeatability, traceability, and standardizable quality control.

- Typical uses: dense hole patterns, pockets/cavities, complex contours, 3D surfaces, critical datum and assembly faces

- Process note: defining datums, critical tolerances, and surface requirements (roughness/cosmetic standard), and completing critical features in fewer setups significantly improves consistency and reduces rework risk.

CNC Milling Types by Machine Capability (Axis Count)

Axis count determines tool access and number of setups, which directly affects positional accuracy and overall cost. Fewer setups usually mean fewer datum transfers and lower cumulative error risk.

3-Axis CNC Milling

3-axis milling covers most functional and structural parts with broad availability and controlled costs. Complex parts may require multiple re-clamps; high positional requirements depend on a strong datum plan and repeatable fixturing.

- Best for: planes, steps, common hole patterns, shallow pockets, simple profiles

- Common issues and fixes:

- Feature-to-feature mismatch after flipping (holes/steps don’t align): machine and “lock in” datum faces/holes first; add locating pin holes or register features for re-clamping; keep critical positional features within one setup when possible.

- Wall waviness / size drift: reduce cutting load (lighter engagement, more finishing passes) and shorten stick-out to increase rigidity; for thin walls, improve support and use staged machining to reduce clamping distortion.

Indexing / 3+2 Milling (Positional Multi-Axis)

This approach reduces setups by indexing the part to multiple orientations while most cutting is performed like stable 3-axis machining. It is a common balance between complexity and cost.

- Best for: multi-direction tapped holes, multi-face hole patterns, multi-face assembly features

- Common issues and fixes:

- Multi-face tolerance stack variation: standardize the “datum—process order” to avoid frequent datum changes; finish critical faces/holes under the same locating scheme and validate repeatability during first-article runs.

4-Axis CNC Milling (Indexing with Rotary Axis)

4-axis adds a rotary axis for indexed machining, ideal for circumferential patterns and repeated side features. Quality stability depends on indexing accuracy and fixture reliability.

- Best for: circular bolt patterns, side slots, repeated circumferential features

- Common issues and fixes:

- Angular error / accumulated pitch error: align the workpiece axis with the rotary axis; use reliable center or datum-hole locating; for critical holes, establish them first and then use stable finishing routes (ream/boring) to reduce side-force sensitivity.

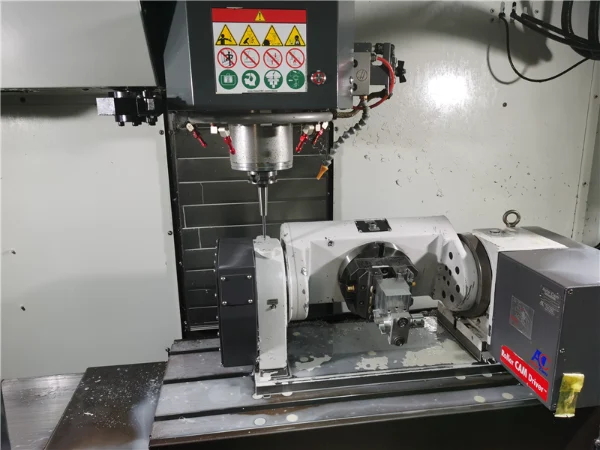

5-Axis CNC Milling (Continuous Simultaneous)

5-axis is used for complex surfaces, angled holes, and hard-to-reach walls. It improves surface quality and positional stability by reducing long-reach tooling and setups. Simulation and process validation are essential to avoid collisions or overcuts.

- Best for: complex 3D surfaces, angled holes, deep-wall finishing, high positional multi-face assemblies

- Common issues and fixes:

- Surface waviness / visible blend lines: tighten scallop control and smooth toolpath transitions; reduce abrupt direction changes; control tool runout and use a rigid holder system to prioritize consistent finish.

- Overcut/interference risk: ensure adequate clearance and retract space; select appropriate tool taper/length; simulate and validate critical zones with trial cuts before locking the process.

CNC Milling Types by Machine Structure

Machine structure affects rigidity, chip evacuation, and workable part size—critical for deep cavities, long-travel planes, and large components.

Vertical Milling

Highly versatile for small-to-mid parts. Deep cavities are more prone to chip recutting, so chip-evacuation toolpaths and clearing routines are important.

- Common issue and fix:

- Deep-pocket wall scratches: use layered roughing and chip-friendly toolpaths (e.g., helical entry, periodic lifts to clear chips), and optimize coolant/air direction to prevent recutting.

Horizontal Milling

Better natural chip evacuation, often preferred for deep cavities, box parts, multi-face machining, and production stability. It requires disciplined fixture/datum planning.

- Common issue and fix:

- Multi-face inconsistency: keep fixture datums aligned with drawing datums; use repeatable locating (pins + register surfaces); standardize operation order and finish critical features under one locating scheme.

Gantry (Large-Travel) Milling

Used for large parts and long planar travel. Flatness can be influenced by residual stress and temperature gradients; staged removal and stabilization steps are often necessary.

- Common issue and fix:

- Flatness variation: apply symmetric material removal and zoned machining; rough first, stabilize, then finish; for sensitive parts, use more stable stock or add intermediate stabilization/stress-relief steps.

CNC Milling Types by Feature (Geometry-Driven Methods)

Feature-based classification maps directly to real part geometry. Different features vary in sensitivity to tooling rigidity, chip evacuation, and surface finish control.

Face Milling

Used to create large planes and establish datum surfaces. Quality depends on cutter stability, path strategy, and machine rigidity.

- Common issues and fixes:

- Uneven pattern / glossy patches: check cutter runout and insert height consistency; keep a stable direction and continuous passes on cosmetic faces.

- Unstable flatness: separate roughing and finishing; zone large faces and manage heat; use staged removal to reduce stress release effects.

End Milling

The most universal method for walls, steps, profiles, roughing, and semi-finishing.

- Common issues and fixes:

- Wall waviness / corner overcut: reduce stick-out and improve clamping; finish with light engagement and multiple passes to minimize deflection; add a light “spring pass” if needed to stabilize size.

Pocket/Cavity Milling

Used for cavities and weight reduction. Deep pockets are sensitive to chip evacuation and heat.

- Common issues and fixes:

- Galling/scratches on walls: optimize chip evacuation paths and clearing rhythm; finish floors with smoother, consistent toolpaths to unify texture.

- Inconsistent pocket depth: use a controlled finishing floor pass and increase in-process checks to prevent drift from heat/load changes.

Slot Milling

Used for guide slots, keyways, and retention features. Deep narrow slots elevate load and chip evacuation challenges.

- Common issues and fixes:

- Unstable slot width / breakage risk: avoid full-width heavy slotting; use step-over side milling in layers; prioritize short, rigid tools and add chip clearing cycles.

- Heavy burrs: maintain sharp tooling and appropriate direction; specify edge break and deburring expectations for assembly-critical edges.

Profile/Contour Milling

Defines outer geometry and boundary lines; critical for fit and cosmetic consistency.

- Common issues and fixes:

- Edge chipping / cosmetic scratching: keep tools sharp and prevent chip recutting; use continuous finishing contours and consistent mark direction; add a light secondary finish pass if needed for edge quality.

- “Stepped” profile look: tighten step-over and smooth linking moves to reduce witness lines.

3D Surface Milling

Used for complex surfaces using ball or corner-radius tools; results depend on scallop control and transition smoothness.

- Common issues and fixes:

- Waviness / witness seams: reduce scallop height targets and improve blending; control runout and holder rigidity; use smoother paths to reduce dynamic artifacts from acceleration changes.

Hole Making on Milling Machines (Drill/Ream/Bore Routes)

Hole quality depends heavily on the process route. Precision holes often require finishing operations beyond drilling.

- Common issues and fixes:

- Diameter variation / poor roundness: use a stable finishing route (reaming/boring) for fit holes instead of drilling to size; keep critical holes within one datum scheme and strengthen measurement feedback.

- Positional drift: reduce datum transfers/setups; standardize the machining order around primary datums.

Thread Milling

Thread milling is well-suited for difficult materials or when thread consistency is critical. Risk is more controllable than tapping in many cases.

- Common issues and fixes:

- Incomplete threads / interference / gauge failure: verify retract space and hole-bottom geometry; calibrate thread compensation and tool-wear compensation; for difficult materials, use more conservative staged cutting for stability.

CNC Milling Types by Toolpath and Cutting Strategy

Strategy determines whether cutting load is stable, which affects chatter, thermal drift, finish defects, and tool life.

Roughing vs Finishing

Roughing focuses on removal rate and chip stability; finishing focuses on size, surface, and positional relationships. Separating rough/finish and leaving appropriate stock reduces drift and finish risk, especially for thin walls, long parts, and multi-face assemblies.

Dynamic/Trochoidal Milling

Maintains more constant tool load to reduce heat and shock, particularly effective for deep-pocket roughing and tougher materials. It is commonly used to improve process stability and reduce breakage.

High-Speed Milling (HSM)

Can improve efficiency and surface quality under proper conditions, but demands strong machine dynamics, tool balance, and chip evacuation. For cosmetic goals, smooth transitions and stable tooling typically matter more than simply increasing speed.

High-Feed Milling

Effective for large-area roughing with shallow depth and high feed, but relies heavily on rigidity and toolpath control. Thin-wall parts require cautious staging to avoid deformation and size variability.

CNC Milling Types by Material and Operating Condition

Material changes wear mechanisms, thermal behavior, burr formation, and defect modes, so material-driven methods are important for stable routing and risk control.

Aluminum Milling

High efficiency for structural and cosmetic parts.

- Common issues and fixes:

- Built-up edge / fuzzy surfaces: use sharp tools and keep chip evacuation effective to reduce edge smearing; keep cosmetic finishing passes continuous to maintain uniform texture.

- Chip scratches on cosmetic faces: improve chip direction/clearing rhythm to prevent recutting; add a dedicated finishing path to unify tool marks where needed.

Stainless Steel Milling

Heat concentration, faster tool wear, and stubborn burrs are common.

- Common issues and fixes:

- Burning/galling and short tool life: use a steadier load with effective coolant/evacuation; avoid running after tool dulling, which amplifies defects; apply stable roughing approaches for deep pockets/high removal.

- Heavy/inconsistent burrs: define edge break and deburring standards; add dedicated deburring for critical holes and assembly edges to prevent functional issues.

Titanium Milling

Low thermal conductivity and high cutting temperature narrow the process window and increase tool cost.

- Common issues and fixes:

- Edge chipping / high-temperature wear: control heat and load, avoid long “rubbing” contact; prioritize stable removal and reduce dwell; validate critical regions with trial cuts before finalizing the process.

Engineering Plastic Milling (POM/PA/PEEK, etc.)

Plastics are more sensitive to heat and clamping deformation.

- Common issues and fixes:

- Melting/smeared edges, glossy patches: use sharp tools and reduce heat buildup; prefer air/mist approaches when appropriate to limit local softening.

- Stringing/fuzz and unclear edges: optimize direction and chip clearing; add a light finishing pass to clean edges; specify consistent edge break requirements.

- Clamping distortion and unstable size: use uniform support and gentler clamping; stage machining on thin sections and re-locate before finishing when needed.

Summary: CNC Milling Type Selection Is About Process Match and Stability

“CNC milling type” can be viewed as a framework composed of milling mode (manual vs CNC) + axis capability + machine structure + feature-based methods + toolpath strategy + material condition. By defining critical features, datums, tolerance/surface standards, and matching the right machine capability and process strategy, setups and cumulative errors can be reduced, chatter and finish defects can be minimized, and batch consistency can be improved—making cost and lead time more predictable.if you want get more information or quote from a reliable precision milling manufacturer,you can contact with us Weldo machining now.