When engineers design parts for sliding, friction, wear, and heavy-load applications, bronze is still one of the most reliable material choices. Even today, with advanced coatings and engineering plastics, CNC bronze machining remains essential for manufacturing bearings, bushings, gears, wear plates, and high-reliability mechanical components.

Bronze is not chosen because it is lightweight or cheap, but because it offers:

- Predictable wear behavior

- Long service life

- Stable performance under load

- Excellent corrosion resistance

When Does Bronze Make More Sense Than Steel or Aluminum?

Bronze is usually the better choice when parts operate under:

- Sliding contact instead of rolling contact

- Continuous friction and wear

- Heavy load or impact load

- Limited lubrication or dry-running conditions

- Humid, marine, or corrosive environments

Because of these properties, bronze is widely used in:

- Bearings and bushings

- Sliding blocks and guide components

- Gears and wear plates

- Valve and pump components

- Heavy-duty machinery and marine equipment

What Makes Bronze a Special Engineering Material?

Bronze is not just a copper alloy. It is a purpose-built wear material designed for long-term stability.

| Property | Engineering Value |

|---|---|

| Excellent wear resistance | Ideal for sliding and friction parts |

| Good self-lubrication | Reduces or eliminates external lubrication |

| High load capacity | Suitable for heavy-duty structures |

| Good machinability | Easier to machine than many steels |

| Excellent corrosion resistance | Perfect for marine and harsh environments |

In practice, this means:

- Longer service life

- Lower maintenance cost

- More stable system performance

Common Bronze Types for CNC Machining and Their Applications

Different applications require different bronze alloys. Below are the most commonly used bronze materials in CNC machining.

Tin Bronze

Tin bronze is known for good wear resistance, stable strength, and excellent friction performance. It performs reliably under medium speed and medium-to-high load conditions. It is commonly used for bushings, bearings, gears, sliders, and wear sleeves.

Machining Recommendations

- Tooling:

Use general-purpose carbide tools with good edge sharpness and wear resistance. - Cutting parameters:

Use medium to high cutting speeds and stable feed rates to achieve good surface finish. - Machining notes:

Some grades are slightly tough and may produce continuous chips; proper chip breaking and coolant use are recommended.

Aluminum Bronze

Aluminum bronze is a high-strength, highly corrosion-resistant bronze alloy and one of the strongest bronzes available. It performs extremely well in seawater, chemical environments, and heavy-load applications. It is commonly used for heavy-duty gears, pump and valve parts, marine components, and structural parts.

Machining Recommendations

- Tooling:

Use high-quality, wear-resistant carbide tools or coated inserts, because this material is strong and abrasive. - Cutting parameters:

Use lower cutting speeds and conservative feed rates compared to tin or lead bronze to protect tools. - Machining notes:

Generates high cutting forces and heat; rigid fixturing and sufficient cooling are strongly recommended.

Phosphor Bronze

Phosphor bronze is famous for excellent elasticity, fatigue resistance, and good wear resistance. It maintains stable mechanical performance under repeated loading. It is commonly used for springs, electrical contacts, precision sliding parts, and wear pads.

Machining Recommendations

- Tooling:

Use sharp carbide tools or fine-grain carbide inserts to handle its higher toughness. - Cutting parameters:

Use moderate cutting speeds and controlled feed rates to avoid work hardening and tool wear. - Machining notes:

This material is more ductile; stable setups and good chip evacuation are important for consistent quality.

Lead Bronze

Lead bronze is characterized by excellent self-lubrication and very low friction coefficient. It performs very well under low-speed and heavy-load conditions. It is commonly used for sliding bearings, bushings, and heavy-duty wear sleeves.

Machining Recommendations

- Tooling:

Use sharp carbide tools or polished inserts to prevent material smearing and built-up edge. - Cutting parameters:

Can use relatively high cutting speeds and moderate feed rates because this material machines easily and breaks chips well. - Machining notes:

The material is soft and may smear if tools are not sharp; keep tools clean and avoid excessive heat buildup.

Beryllium Bronze

Beryllium bronze is a high-performance copper alloy combining high strength, high elasticity, and extremely high fatigue life. It also offers good conductivity and corrosion resistance. It is commonly used for precision springs, connectors, mold components, and high-end mechanical parts.

Machining Recommendations

- Tooling:

Use premium carbide tools or coated tools with high wear resistance, and keep cutting edges sharp. - Cutting parameters:

Use moderate cutting speeds and stable feed rates, avoiding aggressive cutting to reduce tool wear and heat. - Machining notes:

Pay attention to dust and chip control; proper extraction and safety measures should be used due to health considerations.

High-Strength Wear-Resistant Bronze

This type of bronze is specially designed for extreme wear and high-load applications. It remains stable under continuous friction and impact loads. It is commonly used for heavy machinery sliding parts, guide rails, support components, and special bushings.

Machining Recommendations

- Tooling:

Use heavy-duty carbide tools or coated inserts designed for abrasive materials. - Cutting parameters:

Use lower cutting speeds and stable, conservative feed rates to maintain tool life and dimensional accuracy. - Machining notes:

These alloys are designed for durability, not machinability; expect higher tool wear and plan processes accordingly.

General Machining Tips for CNC Bronze

- Always use sharp tools to avoid built-up edge and surface tearing

- Ensure good chip evacuation, especially for ductile bronze alloys

- Use coolant or air blast to control temperature and improve surface finish

- For high-precision parts, consider finishing passes, grinding, or honing

How Machinable Is Bronze?

In general, most bronze alloys have good machinability, but their cutting behavior varies by alloy type.

- Lead bronze and some tin bronzes – Very easy to machine, with good chip breaking and stable surface finish, ideal for high-volume production.

- Phosphor bronze – Moderate machinability, tougher and more ductile, requiring sharper tools and optimized parameters.

- Aluminum bronze and beryllium bronze – Much harder and stronger, requiring lower cutting speeds, rigid setups, and better tool quality.

- Compared with steel – Most bronzes cut more smoothly and produce better surface finish, but some grades are prone to built-up edge.

Is Bronze Harder to Machine Than Brass?

In most cases, bronze is harder to machine than brass.

- Brass – Extremely easy to machine, with excellent chip control, low cutting force, and very high cutting speeds.

- Bronze – Tougher and more ductile, higher cutting resistance, and more sensitive to tool geometry and parameters.

- Production efficiency – Brass is faster and cheaper to machine, while bronze usually requires more careful process control.

- Performance trade-off – Bronze is chosen for wear resistance and load capacity, not for machinability.

What Is the Best Bronze for Machining?

There is no single “best” bronze, only the best choice for your application.

- Best for easy machining – Lead bronze and some tin bronzes, offering stable cutting and lower tool wear.

- Best for high strength and heavy load – Aluminum bronze and beryllium bronze, offering excellent strength but lower machining efficiency.

- Best for fatigue and elastic parts – Phosphor bronze and beryllium bronze, designed for repeated stress and long service life.

- Selection logic – The right bronze depends on whether you prioritize machinability, strength, wear resistance, or fatigue performance.

The right bronze grade can reduce lifetime cost even if machining cost is higher.

The Corrosion Resistance of Bronze

One major reason bronze is widely used is its excellent corrosion resistance, especially in harsh environments.

- Bronze does not rust like steel

Because bronze contains no iron, it does not form red rust, and its surface oxidation layer is stable and protective, helping prevent further material degradation. - Performs very well in marine and humid environments

Many bronze alloys, especially aluminum bronze and tin bronze, maintain stable performance in seawater, coastal, and high-humidity environments where steel would corrode quickly. - Good resistance to many chemicals and industrial atmospheres

This makes bronze suitable for pumps, valves, and fluid-handling systems where long-term material stability is critical.

This is why bronze is commonly used in ships, pumps, valves, outdoor equipment, and coastal or chemical machinery.

Brass or Copper: Which Is Better for CNC Machining?

From a machining perspective, brass is much better than pure copper.

- Brass: easy chip breaking, high cutting speed, excellent surface finish

Brass machines cleanly and consistently, allows very high productivity, and is ideal for precision parts, fittings, and high-volume CNC production. - Pure copper: very soft, very sticky, difficult to machine

Copper tends to form long, sticky chips, causes tool buildup, and usually requires special tooling and conservative cutting parameters. - Different application focus

Copper is mainly selected for electrical and thermal conductivity, while brass is chosen for mechanical parts, connectors, and components where machinability and dimensional accuracy are more important.

In short: brass is chosen for manufacturing efficiency, copper is chosen for functional conductivity.

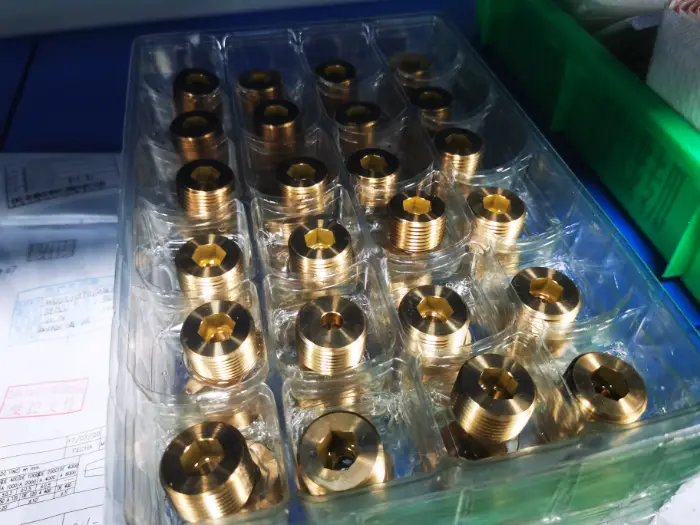

How Are CNC Bronze Parts Manufactured?

CNC bronze parts are typically produced using precision subtractive machining processes from bar, plate, or forged materials, and different processes are combined depending on part geometry, tolerance, and surface requirements.

- CNC turning (bushings, sleeves, bearing parts)

Mainly used for round and rotational parts, and is the most common process for producing bronze bearings, bushings, and sleeves with tight tolerances and good concentricity. - CNC milling (blocks, complex shapes)

Used for structural parts, wear plates, and complex geometries that require accurate profiles, pockets, and multi-axis machining. - Mill-turn machining

Combines turning and milling in one setup, improving positional accuracy, concentricity, and overall production efficiency for complex functional components. - EDM (Electrical Discharge Machining)

Used for machining complex internal shapes, deep slots, or features that are difficult to cut with conventional tools, especially when high precision or sharp internal corners are required. - CNC grinding

Applied when parts require very tight tolerances, high dimensional accuracy, or superior surface finish, especially for bearing surfaces and critical fitting areas. - Drilling, boring, tapping, and precision finishing

These secondary operations are used to achieve precise fits, smooth surfaces, and reliable assembly performance in critical components.

Typical tolerance capability:

- Standard machining: ±0.05 ~ ±0.1 mm

- Precision machining: ±0.01 ~ ±0.02 mm

For bearing and sliding parts, additional honing, grinding, or fine finishing processes may be used to further improve surface quality, accuracy, and service life.

Is Bronze Expensive?

Bronze is generally more expensive than aluminum and carbon steel, but the actual cost depends heavily on the specific bronze alloy and the copper market price.

Below are typical raw material price ranges (approximate, for bar/plate stock, USD per kg):

- Lead bronze: ≈ $8 – $12 / kg

One of the most cost-effective bronzes, widely used for bearings and bushings. - Tin bronze: ≈ $9 – $14 / kg

Balanced in price and performance, very common in general wear parts. - Phosphor bronze: ≈ $10 – $16 / kg

Slightly more expensive due to better fatigue and elastic properties. - Aluminum bronze: ≈ $12 – $20 / kg

Higher cost because of high strength and excellent corrosion resistance. - Beryllium bronze (Beryllium copper): ≈ $30 – $60+ / kg

One of the most expensive copper alloys due to its exceptional strength, elasticity, and fatigue performance.

These are material-only costs. Final part price also depends on:

- Machining time and difficulty:The more difficult the processing, the longer the processing time, and naturally, the higher the processing cost.

- Tool wear:Different types of bronze require different cutting tools for processing, and the prices of these tools vary. For harder types of bronze, the cutting tools are generally more expensive, resulting in higher costs.

- Tolerance and surface finish requirements:Excessively strict tolerance standards and surface finish requirements can significantly increase manufacturing difficulty. Appropriately controlling tolerances and surface finish standards can make costs more manageable.

- Part size and quantity:The larger the size and volume, the higher the cost of raw materials; the greater the quantity processed, the lower the processing cost per unit will be.

However, in many applications:

Although bronze parts cost more upfront, they often reduce total lifetime cost because of longer service life, lower maintenance, and fewer failures.

Bronze vs Steel vs Aluminum: Which One Should You Choose?

| Property | Bronze | Steel | Aluminum |

|---|---|---|---|

| Wear Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐ |

| Self-Lubrication | ⭐⭐⭐⭐ | ⭐ | ⭐ |

| Strength | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

| Cost | Medium–High | Medium | Low |

If your part is about sliding, wear, and long-term reliability, bronze is usually the right answer.

Final Thoughts: CNC Bronze Is Not Old, Still Irreplaceable

CNC bronze machining is not a traditional solution, but a proven and irreplaceable engineering solution. In bearings, wear parts, sliding systems, and heavy-duty machinery, bronze still offers a unique combination of reliability, predictability, and durability.

Choosing the right bronze alloy is not just a material decision — it is a system reliability decision.