PTFE (Polytetrafluoroethylene) and HDPE (High-Density Polyethylene) are two widely used engineering plastics. Although both are plastics, they differ greatly in structure, temperature and chemical resistance, mechanical behavior, machinability, and cost. These differences directly affect part performance, service life, and manufacturing cost.

In engineering, material selection is not about choosing the “better” material, but about:

Choosing the material that meets application needs without unnecessary risk or cost.

This article compares PTFE and HDPE from an engineering perspective, covering properties, manufacturing and machining, advantages and limitations, cost, and practical selection guidelines.

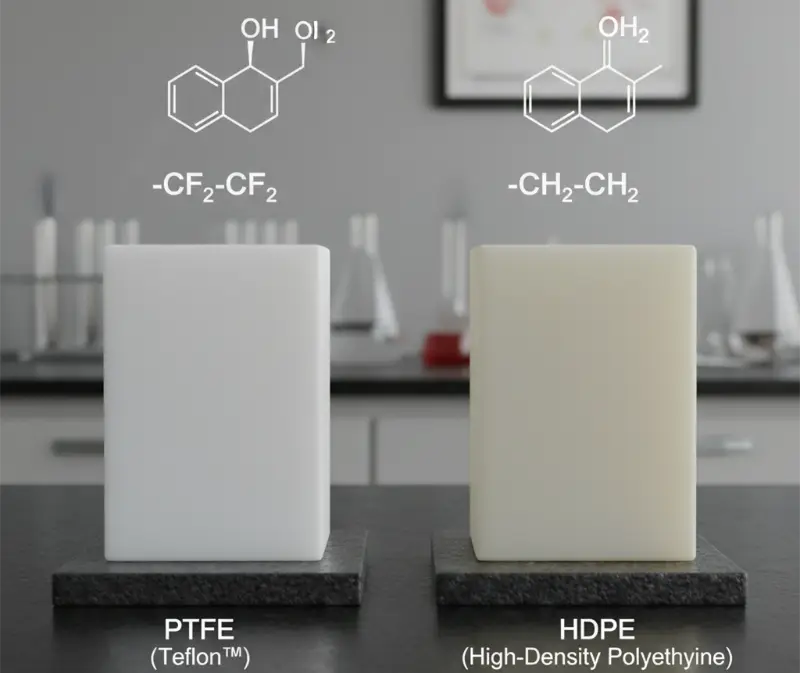

Molecular Structure and Material Fundamentals

PTFE (Polytetrafluoroethylene)

- Chemical formula: (C₂F₄)ₙ

- Structure: Carbon chain fully shielded by fluorine atoms

This structure leads to several important engineering consequences. First, PTFE has extremely low surface energy and therefore excellent self-lubricating and non-stick properties. Second, the fluorine “shell” makes the material chemically inert to almost all chemicals, including strong acids, strong bases, and most solvents. However, the same structure also causes PTFE to exhibit pronounced creep (cold flow), meaning it slowly deforms under long-term load.

For this reason, PTFE is ideal for sliding and sealing components, but it is not suitable for load-bearing structural parts that require long-term dimensional stability. Many real-world failures of PTFE parts are not caused by insufficient strength, but by long-term deformation that leads to loss of fit or sealing failure.

HDPE (High-Density Polyethylene)

- Chemical formula: (C₂H₄)ₙ

- Structure: Linear polyethylene with high crystallinity

Although the molecular structure of HDPE is relatively simple, its high crystallinity gives it a good balance of toughness, impact resistance, stiffness, and dimensional stability. From an engineering point of view, this means HDPE is neither brittle nor excessively soft, and it performs reliably under typical mechanical loads.

In addition, HDPE is a very manufacturing-friendly material. This has major practical significance in engineering: not only is it easy to process, but the manufacturing risk and scrap cost are also relatively low. This is why HDPE is widely used for large structural parts, support components, and cost-sensitive applications.

Mechanical and Physical Properties Comparison (with Engineering Meaning)

| Property | PTFE | HDPE | Engineering Meaning |

|---|---|---|---|

| Density | ~2.15 g/cm³ | ~0.95 g/cm³ | PTFE is much heavier |

| Service temperature | -180 to +260°C | -50 to +80°C | High-temperature applications require PTFE |

| Friction coefficient | ~0.04 | ~0.2 | PTFE offers true self-lubrication |

| Tensile strength | ~20–30 MPa | ~20–35 MPa | Similar strength level |

| Stiffness | Low | Medium | HDPE is more suitable for structural parts |

| Creep resistance | Poor | Better | PTFE deforms under long-term load |

| Chemical resistance | Almost universal | Good for most media | PTFE preferred in aggressive environments |

From an engineering perspective, these parameters are not independent. Operating temperature usually determines whether a material is usable at all. Friction coefficient determines whether additional lubrication is needed and affects maintenance cost. Creep resistance determines whether a part will slowly and irreversibly change shape over time.

In practice, many plastic parts fail not because they are “not strong enough,” but because they slowly deform under heat or sustained load, eventually causing assembly or sealing failure. At this level, the functional roles of PTFE and HDPE are already largely defined.

Manufacturing Processes Supported by Each Material

PTFE: Manufacturing Methods and Limitations

PTFE does not melt and flow like normal thermoplastics; instead, it tends to decompose when heated. Therefore, it is:

- ❌ Not suitable for conventional injection molding

- ❌ Not suitable for standard extrusion

- ✅ Typically manufactured by: Cold pressing powder → Sintering → CNC machining

This process chain means long manufacturing cycles, unavoidable shrinkage, low material utilization, and heavy reliance on machining for final accuracy. As a result, PTFE parts are expensive not only in material cost, but also in processing cost and manufacturing risk.

Typical PTFE parts include seals, gaskets, bushings, sleeves, sliders, valve seats, and electrical insulators. Their common feature is that functional performance is far more important than load-bearing capability.

HDPE: Manufacturing Methods

Compared with PTFE, HDPE is a very “manufacturing-friendly” material. It can be:

- CNC machined from sheets or rods

- Injection molded

- Extruded

- Thermoformed

- Welded

This flexibility is extremely valuable in practice. For large batch production, molding can significantly reduce unit cost; for small batches or custom parts, CNC machining allows fast and economical manufacturing.

This dual capability—scalable mass production and flexible customization—is one of the main reasons HDPE is widely used for machine structures, guards, supports, and protective components.

Process Comparison

| Process | PTFE | HDPE |

|---|---|---|

| CNC machining | ✅ | ✅ |

| Injection molding | ❌ | ✅ |

| Extrusion | ⚠️ Special | ✅ |

| Compression molding & sintering | ✅ | ❌ |

| Welding | ❌ | ✅ |

| Thermoforming | ❌ | ✅ |

CNC Machining Considerations for PTFE

PTFE is very soft, elastic, and exhibits strong creep and spring-back. Typical machining problems include dimensional rebound after machining, round holes becoming oval, thin walls deforming, and surfaces being “pulled” rather than cleanly cut.

Clamping force must be minimized, preferably using soft jaws or large-area support. Point contact and excessive clamping force often cause significant dimensional change after release. Tooling must be extremely sharp with large rake angles; dull tools will tear the material instead of cutting it.

In terms of strategy, light multiple passes with sufficient finishing allowance are preferred. The final finishing cut should be very light to minimize residual stress.

From a design standpoint, thin walls, long cantilevers, and highly load-bearing structures should be avoided. PTFE is best used for rings, sleeves, gaskets, sliders, and seals—functional parts rather than structural parts.

Engineering Pros and Cons of PTFE

Advantages:

- Extremely low friction (self-lubricating)

- Excellent chemical resistance

- Very high temperature resistance

- Non-stick surface

- Excellent electrical insulation

Disadvantages:

- Low stiffness and structural strength

- Severe creep

- Poor dimensional stability in machining

- Cannot be injection molded or welded

- High material and processing cost

CNC Machining Considerations for HDPE

HDPE is tough, relatively soft, heats up easily, and tends to produce long stringy chips. If cutting parameters are not appropriate, typical problems include chip stringing, tool sticking, local melting, and poor edge quality.

Tools should be sharp, polished, and with large rake angles. In terms of cutting parameters, the general rule is:

It is better to cut faster than to rub slowly.

Slow cutting increases frictional heat, which softens the material and causes sticking. Coolant is usually not critical, but chip evacuation is very important.

In terms of fixturing, HDPE is much more stable than PTFE, but large thin plates still require uniform support to avoid deformation.

Engineering Pros and Cons of HDPE

Advantages:

- Low cost

- Easy to machine

- Good dimensional stability

- Tough and not brittle

- Weldable and joinable

- Can be injection molded and extruded

Disadvantages:

- Limited temperature resistance (typically < 80°C continuous)

- Worse friction properties than PTFE

- Slightly inferior chemical resistance compared to PTFE (still good)

- Medium stiffness and strength level

Cost Range and Its Engineering Reasons

In engineering projects, “expensive or cheap” must be judged by total part cost, including material, processing time, yield rate, and manufacturing risk.

| Material | Typical total cost (material + normal machining) |

|---|---|

| HDPE | ~3–8 USD/kg |

| PTFE | ~20–60 USD/kg |

The high cost of PTFE comes from its powder sintering process, long production cycle, low machining efficiency, and high material loss. In real projects, it is very common for a PTFE part to cost 5–10 times as much as an HDPE part of the same volume.

Typical Application Logic

PTFE is widely used in high-temperature, chemically aggressive, and sliding applications not because it is “the best in everything,” but because under these constraints it is often one of the very few materials that can work reliably long-term—especially where lubrication is not allowed or contamination must be avoided.

HDPE is better suited for structural parts and large components because it offers a very balanced compromise between stiffness, toughness, dimensional stability, and cost. Its weldability also enables large fabricated structures, which is a decisive advantage in many equipment designs.

Practical Material Selection Logic

In real engineering projects, material selection is a step-by-step filtering process:

- Check environment (temperature and chemical exposure): can the material survive?

- Check structural and load requirements: will it keep its shape long-term?

- Check functional requirements (sliding, sealing, non-stick, etc.).

- Finally, optimize cost and manufacturing risk.

From this perspective:

PTFE mainly solves functional problems, while HDPE mainly solves structural and cost problems.

Conclusion

PTFE and HDPE are not simply “high-end” and “low-end” materials. They are two solutions aimed at completely different engineering problems. PTFE’s value lies in friction, chemical resistance, and temperature stability. HDPE’s value lies in structural reliability, manufacturing friendliness, and cost control.

In CNC machined parts, understanding this fundamental difference is far more important than simply comparing a few numbers in a datasheet.if you want to know more details,please feel free to contact with us for more details.