When sourcing precision plastic parts, one of the most common questions engineers and buyers ask is: what is the real CNC POM price and what exactly determines it? POM (Polyoxymethylene), also known as Acetal or Delrin, is one of the most widely used engineering plastics in CNC machining due to its excellent strength, wear resistance, and dimensional stability. However, the cost of CNC POM parts can vary significantly depending on material grade, part design, tolerance strategy, and production volume. This article provides a comprehensive engineering-level analysis of CNC POM price, helping you understand not only how much it costs, but why it costs that much.

Understanding POM in CNC Machining

POM is a high-crystallinity engineering thermoplastic known for its outstanding stiffness, fatigue resistance, and dimensional stability. In real industrial applications, it is widely used for gears, bushings, bearing cages, sliding components, rollers, and various precision transmission parts.

Compared with Nylon, POM offers higher rigidity and much lower moisture absorption, which means better dimensional stability over time. Compared with metals such as aluminum or brass, POM provides lighter weight, self-lubricating behavior, lower noise, and usually a significantly lower total manufacturing cost.

Because of this balance, POM has become one of the most cost-effective materials in CNC plastic machining for mechanical functional parts.

Why CNC POM Is Considered a “Cost-Performance Champion”

From a manufacturing perspective, POM occupies a very favorable position among engineering plastics. It machines almost as easily as aluminum, produces stable chips, and does not require secondary processes such as heat treatment, anodizing, or anti-rust coating,This can help save time and costs associated with surface treatment.

In addition, POM has predictable deformation behavior during machining, which makes it much easier to control tolerances compared to many other plastics. Tool wear is relatively low, cycle time is stable, and the scrap rate is easy to control.

In many real projects, CNC POM parts can replace aluminum or brass parts with 30%–60% lower total cost, while still fully meeting mechanical and lifetime requirements.

What Really Determines CNC POM Price?

Material Grade Selection: The First Cost Multiplier

One of the biggest factors behind CNC POM price differences is the material grade. Many buyers only look at the raw material price per kilogram, but in reality, the grade affects the total cost in multiple ways: machining speed, tool life, surface finish difficulty, and scrap risk.

For example, glass fiber reinforced POM is much stronger than standard POM, but it is also more abrasive to tools, requires slower cutting parameters, and is more difficult to control in terms of surface quality. As a result, its total machining cost can easily be 40%–120% higher than standard POM-C or POM-H, even before considering the higher material price itself.

For most mechanical parts, standard POM-C or POM-H (Delrin) already provides more than enough strength and wear resistance, and offers the best cost-performance ratio.

Geometry and Structural Design: The Hidden Cost Driver

In CNC machining pom part, the shape of a component often matters more than its size. Features such as deep cavities, thin walls, long overhangs, or complex 3D surfaces require longer tools, slower cutting parameters, additional machining steps, and more inspection work. All of these factors directly increase machine hours, which are the core cost driver in CNC machining. In practice, a well-optimized design can often reduce the machining cost of POM parts by 20%–40% without changing their function.

| Design Feature / Requirement | Typical Description | Price Impact Range |

|---|---|---|

| Simple geometry | Flat surfaces, basic holes, no deep pockets | Baseline (1.0x) |

| Moderate complexity | Multiple holes, standard slots, simple profiles | +10% – +25% |

| Deep pockets | Pocket depth > 3× tool diameter | +20% – +40% |

| Thin walls | Wall thickness < 1.5 mm | +20% – +50% |

| Tight internal corners | Small radius or sharp internal corners | +15% – +30% |

| Complex 3D surfaces | Curved or freeform surfaces | +30% – +70% |

| Multiple setups | Repositioning required during machining | +20% – +50% |

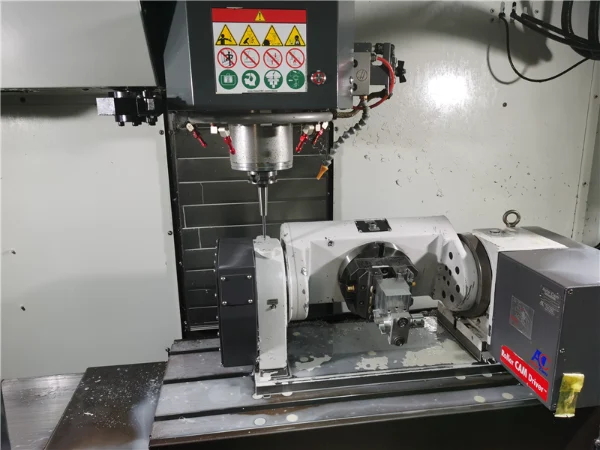

| 5-axis machining | Complex geometry not achievable with 3-axis | +40% – +100% |

Tolerance Strategy: Where Many Projects Burn Money

POM is capable of very tight tolerances, but that does not mean tight tolerances are cheap. Every step tighter in tolerance means slower cutting parameters, more finishing passes, more measurement operations, and higher rejection risk.

In real industrial projects, a very large percentage of parts are over-specified in tolerance. Simply reviewing which dimensions truly need high precision and which do not can often save 15%–30% of total machining cost.

In CNC machining, tolerance requirements have a direct and often underestimated impact on the final cost of POM parts. The following table shows the typical relationship between tolerance level and machining cost in real production.

| Tolerance Level | Typical Range | Machining Difficulty | Cost Impact |

|---|---|---|---|

| Standard | ±0.1 mm | Low | Baseline (1.0x) |

| Medium Precision | ±0.05 mm | Medium | +10% to +25% |

| High Precision | ±0.02 mm | High | +30% to +60% |

| Ultra Precision | ±0.01 mm or tighter | Very High | +60% to +150% |

Batch Size and Production Strategy

CNC POM price also follows a very typical production rule. Prototypes are expensive because programming, setup, and fixture costs are shared by very few parts. As quantity increases, the unit price drops because these fixed costs are diluted and the process becomes more stable and optimized.

For long-term and stable projects, factories often further optimize the process specifically for POM parts, achieving very competitive unit costs in medium and large batch production.

CNC POM Quantity vs Unit Price (Reference)

| Production Type | Typical Quantity | Unit Price Level | Typical Price Change |

|---|---|---|---|

| Prototype | 1–5 pcs | Very High | 1.0x – 1.0x (baseline) |

| Small Batch | 10–100 pcs | High → Medium | ~0.6x – 0.8x |

| Medium Batch | 100–500 pcs | Medium | ~0.4x – 0.6x |

| Large Batch | 500+ pcs | Low | ~0.3x – 0.5x |

Typical CNC POM Price Range (Market Reference)

In the global CNC machining market, typical POM parts usually fall into these ranges:

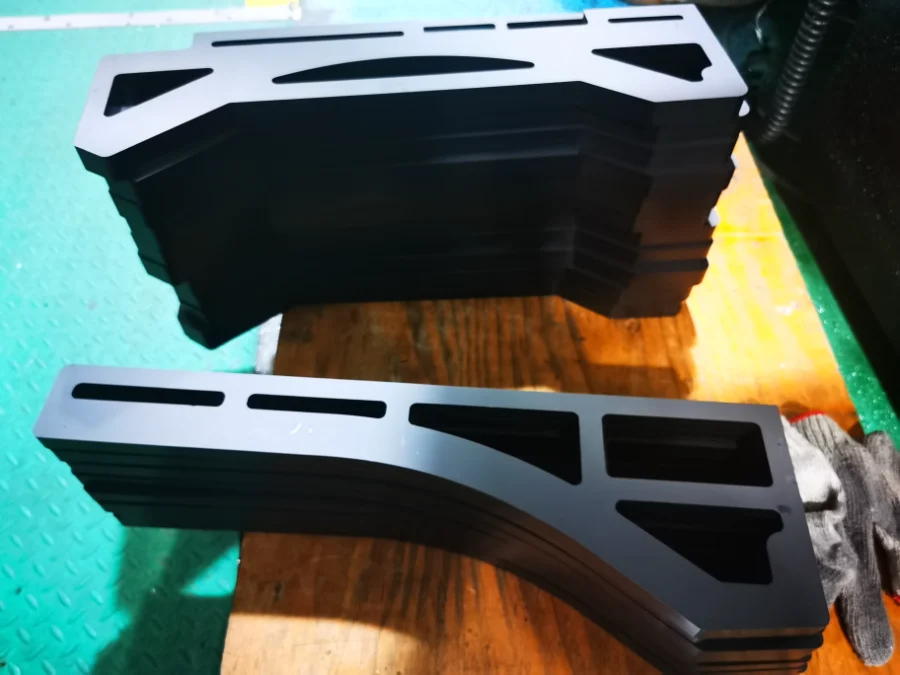

- Simple spacers, sleeves, and bushings: $2 – $10 per piece

- Medium precision functional parts: $10 – $60 per piece

- High-precision transmission or structural parts: $60 – $300+ per piece

The actual price always depends on the drawing, tolerance requirements, surface finish, and order quantity.

POM Mechanical Properties Comparison (Key Grades)

The following table shows the typical mechanical performance differences between common POM grades and is mainly used for engineering material selection.

| Property | POM-C | POM-H (Delrin) | Glass Fiber POM | PTFE-Filled POM |

|---|---|---|---|---|

| Density (g/cm³) | 1.41 | 1.42 | 1.55–1.65 | 1.45 |

| Tensile Strength (MPa) | ~60 | ~70 | 85–110 | ~55 |

| Flexural Strength (MPa) | ~85 | ~100 | 130–160 | ~80 |

| Elastic Modulus (GPa) | ~2.8 | ~3.2 | 5.0–7.0 | ~2.5 |

| Impact Strength (kJ/m²) | ~8 | ~7 | ~6 | ~5 |

| Friction Coefficient | ~0.35 | ~0.35 | ~0.4 | ~0.15 |

| Wear Resistance | Good | Very good | Excellent | Excellent |

| Machinability | Excellent | Excellent | Medium | Good |

| Material Cost | $2.0 – $3.5/kg | $2.5 – $4.0/kg | $1.5 – $2.4/kg | $1.7 – $2.4/kg |

Typical Applications and Selection

Although the mechanical properties table shows the performance differences between various POM grades, in real engineering practice, correct material selection is mainly driven by application type rather than theoretical strength alone. Using the right POM grade not only ensures functional reliability, but also avoids unnecessary cost caused by over-specification.

POM Material Application Guide (Short Version)

POM-C (Copolymer) – General-purpose, best cost-performance, easiest to machine.

Typical parts: sliding blocks, bushings, spacers, low-to-medium load gears, guide parts, rollers, fixtures, and general mechanical components.

POM-H (Delrin) – Higher strength and stiffness than POM-C, for higher load parts.

Typical parts: drive gears, load-bearing bushings, cams, structural supports, high-rigidity sliders, and transmission components.

Glass Fiber POM – High stiffness and structural strength, but not suitable for sliding parts.

Typical parts: load-bearing brackets, frames, mounting bases, structural housings, and reinforcement components.

PTFE-Filled POM – Low friction and self-lubricating, designed for sliding systems.

Typical parts: self-lubricating bushings, sliding bearings, wear pads, silent sliders, maintenance-free guides, and high-speed sliding components.

POM Material Quick Selection Table

| Part Type | Recommended Material |

|---|---|

| Sliding blocks / Bushings / General structural part | ✅ POM-C |

| High-load gears / High-rigidity parts | ✅ POM-H (Delrin) |

| Load-bearing structural components | ✅ Glass Fiber POM |

| High-speed / Maintenance-free sliding parts | ✅ PTFE-Filled POM |

How These Material Differences Affect CNC Machining Cost

Although reinforced or modified POM grades may look much better on paper in terms of strength or friction, in actual machining they usually require more conservative cutting parameters, produce more tool wear, and are more difficult to control in terms of surface finish and dimensional stability.

This is why in many projects, using standard POM-C or POM-H instead of over-specified materials can significantly reduce cost while still fully meeting functional requirements.

POM vs Other CNC Plastics: Cost and Application Logic

In CNC plastic machining, material selection is never only about strength. Nylon is cheaper, but its moisture absorption affects long-term stability. PTFE has excellent chemical resistance, but it is weak and extremely expensive to machine. PEEK is very strong and heat resistant, but its price makes it unsuitable for most cost-sensitive projects.

POM stays in the “sweet spot” between performance, machinability, and cost, which is why it is so widely used in mechanical and automation industries.

Practical Engineering Cost Optimization Suggestions

In real projects, CNC POM machining cost can often be reduced significantly by applying a few simple engineering principles: avoid unnecessary ±0.01 mm tolerances, avoid deep blind pockets and thin unsupported walls, use POM-C instead of Delrin where possible, design parts to be machined in fewer setups, and plan production in reasonable batch sizes instead of no more than 5 PCs orders.

Conclusion

In practice, the CNC POM price is never determined by a single factor, but by the combined result of material selection, part design, tolerance strategy, batch size, and manufacturing efficiency. POM remains one of the most cost-effective engineering plastics because it offers an exceptional balance between mechanical performance, dimensional stability, and machinability. By making rational engineering decisions and working with an experienced CNC supplier, most projects can achieve 20%–50% cost reduction without sacrificing functionality or reliability.