In B2B scenarios where lightweight design, premium appearance, and delivery consistency all matter, CNC aluminum is often a “fast, low-risk, scalable” choice. It supports quick prototyping for validation and enables repeatable quality in volume through stable processes and inspection methods. For procurement teams, the real challenge isn’t “can it be made,” but how to combine material, machining process, surface finishing, and tolerances to optimize cost, lead time, and quality.

Below, we address common buyer questions, and expand into pricing drivers, material selection, quality control, and cost-down strategies, so you can turn the information into an actionable sourcing plan.

What is CNC aluminum?

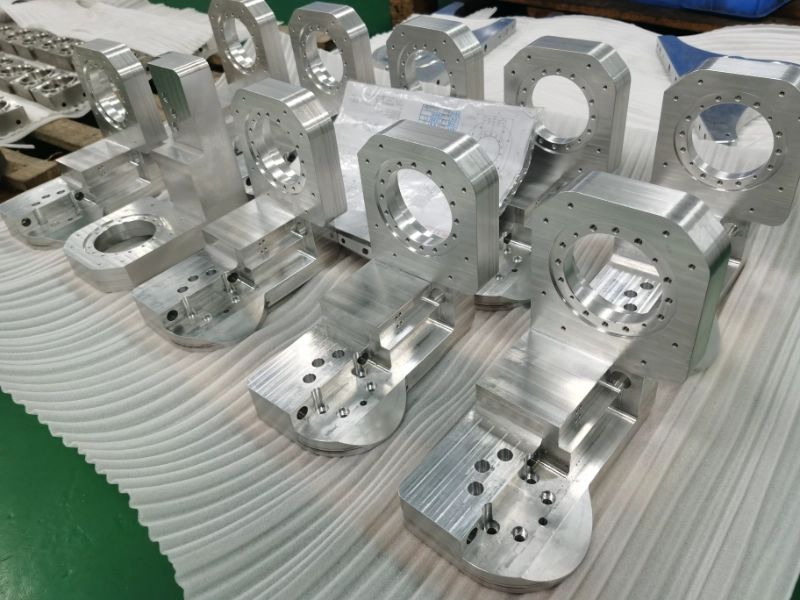

What is CNC aluminum? Simply put, CNC aluminum refers to aluminum or aluminum-alloy parts manufactured using CNC (Computer Numerical Control) machines through operations such as milling, turning, drilling, tapping, and boring to achieve precise geometry and repeatability.

From a procurement perspective, it usually implies two dimensions:

- Material dimension: The workpiece is aluminum or an aluminum alloy (common grades include 6061, 6063, 7075, 5052, 2024, etc.).

- Delivery dimension: The supplier can deliver parts that meet drawing requirements for dimensions, tolerances, surface finishing, and inspection—with consistent results across batches.

Key point: The value of CNC aluminum isn’t just “it can be made,” but traceable manufacturing (toolpaths/fixtures/inspection) + repeatable consistency.

Can a CNC machine cut aluminum?

A frequent buyer question is: can a cnc machine cut aluminum? The answer is yes—very commonly. Aluminum generally has lower cutting resistance than steel or titanium, enabling higher material removal rates and efficient production, which is why it’s widely used for prototypes and small-to-mid volume runs.

In B2B projects, however, “can cut” is only the baseline—what matters is stable machining, clean surfaces, and consistent dimensions. Common risks in aluminum machining include:

- Built-up edge / tool sticking: Poor tool choice or parameters can cause surface tearing and heavier burrs.

- Thin-wall deformation: Lightweight thin sections can distort from clamping force or cutting load.

- Chip scratching: Inadequate chip evacuation or handling can scratch cosmetic surfaces.

Key point: To evaluate a supplier, ask how they manage tooling strategy, coolant approach, and thin-wall fixturing, and during first-article approval focus on cosmetic surfaces, hole position/coaxiality, and burr control—these often reveal real capability more than a generic “we can hold tight tolerances.”

Is CNC aluminum good?

Is CNC aluminum good? For most B2B structural parts, cosmetic housings, and thermal components, the answer is yes—balanced and practical. Aluminum alloys perform well across weight, machinability, corrosion resistance, and finishing compatibility, making them ideal for projects with rapid iteration and frequent revisions.

Core advantages (with procurement context)

- Lightweight with strong structural efficiency: Great for mobile equipment, automation assemblies, and enclosures.

Added value: Lower weight can reduce logistics cost and improve dynamic performance (acceleration, energy use, noise), which is often an overlooked procurement benefit. - High machining efficiency and faster delivery: Typically faster cycle times than steel/titanium.

Added value: CNC aluminum often shortens the “design → validation → production” loop, reducing project delays that translate into real business cost. - Many finishing options with strong cosmetic consistency: Anodizing, bead blasting, hard anodizing are mature and scalable.

Added value: If branding appearance matters, define color standards and sample approval at the RFQ stage to avoid disputes from color variation later. - Excellent thermal conductivity: Ideal for heatsinks, thermal bases, and integrated heat-management housings.

Added value: For thermal parts, surface roughness and flatness at mating interfaces directly affect thermal performance—specify what matters.

Limitations to keep in mind (avoid “wrong material” decisions)

- Strength/wear ceiling is lower than steel: High load or high wear may require steel or surface hardening strategies.

- High-strength alloys (7075/2024) are less corrosion-resistant: They rely more on finishing and environment control.

Key point: For “cosmetic + light structural” parts, 6061/6063 is often the best value; for high-load structural components, consider 7075 with a defined corrosion/finishing plan.

Is CNC aluminum expensive?

Is CNC aluminum expensive? The most useful procurement conclusion is: unit cost is driven more by machining time and quality requirements than by aluminum itself.

In practical comparisons:

- Versus CNC stainless/titanium: CNC aluminum is often cheaper (faster machining, lower tool wear).

- Versus injection molding/die casting: CNC may be higher per unit at low volume, but offers fast development and easy design changes.

- Versus extrusion/forging + secondary machining: full CNC-from-solid can be higher cost, but with lower upfront investment—best when demand is uncertain.

What really drives price (define these clearly in RFQ)

- Machining time (Cost Driver #1): deep pockets, complex surfaces, thin walls, frequent tool changes increase cost.

- Tolerances and inspection: tighter tolerances often require slower machining, extra setups, and more metrology.

- Finishing and cosmetic standards: anodize color control, “A-surface” requirements, masking and hanger-mark limits add cost.

- Quantity and fixturing: prototypes are expensive per unit; larger quantities spread programming/setup costs.

Key point: To make quotes comparable, specify tolerance classes, key dimensions, cosmetic surface definitions, finishing requirements, and inspection methods (sampling vs. 100%, CMM reports, etc.). Otherwise price differences often reflect different assumptions—not supplier inconsistency.

How to choose common aluminum alloys

The selection logic: first categorize by load/function, cosmetic requirements, corrosion environment, and cost, then choose the grade that can deliver stable production consistency. If there’s no strong constraint, start with 6061.

6061-T6 (best all-around default)

- Machining & part characteristics: excellent machinability and dimensional stability; great for multi-op milling and mill-turn; reliable for threaded holes, locating features, and functional mating surfaces.

- Typical applications: automation brackets/bases, electronic structural parts, jigs/fixtures, thermal base plates, general connectors.

- Procurement note: 6061 tends to be the most production-stable option with lower rework risk—ideal as the baseline material.

6063 (cosmetic + anodizing performance)

- Machining & part characteristics: excellent for cosmetic components and profile-type structures; anodizing can achieve finer, more uniform appearance.

- Typical applications: housings, panels, decorative frames, lighting structures, extrusion parts with CNC secondary machining.

- Procurement note: If batch-to-batch cosmetic consistency is critical, 6063 is often easier to control; confirm strength for load-bearing use.

7075-T6 (high-strength structural)

- Machining & part characteristics: high strength and rigidity; suitable for high-load structures and thin-wall load-bearing designs; higher material cost and typically higher process demands; relatively lower corrosion resistance.

- Typical applications: drone/robot load arms, motorsport structural connectors, critical load-bearing fixture components, aerospace-grade structural parts (non-extreme corrosion environments).

- Procurement note: If you select 7075, define finishing and environmental protection early—otherwise corrosion-related risk can increase TCO.

5052 (corrosion resistance + forming-friendly)

- Machining & part characteristics: widely used in sheet forming (bending/drawing) with good corrosion resistance; CNC machining is possible but less common than 6061 for complex precision parts.

- Typical applications: sheet-metal housings, covers, guards, plate-type parts for humid/coastal environments.

- Procurement note: Great for “sheet-forming + light CNC secondary ops.” For fully CNC-from-solid precision parts, 6061 is usually preferred.

2024 (high strength, more dependent on protection)

- Machining & part characteristics: high strength and good fatigue performance; commonly used in aerospace; lower corrosion resistance makes finishing/environment control more important.

- Typical applications: fatigue-sensitive structural parts, aerospace-related components, high-strength projects with controlled specifications.

- Procurement note: Put finishing, corrosion-resistance acceptance, and packaging protection into the RFQ/inspection plan to reduce downstream disputes.

Alternatives Material to CNC Aluminum

Before choosing an alternative to CNC aluminum, be sure to make your decision based on the actual priority requirements of the part (such as load, wear, temperature, corrosion, appearance, or mass production costs). The best alternative material is rarely the “strongest” material; rather, it’s the material that minimizes risk and reduces overall costs in a specific application scenario.

Metal Alternatives (Strength / Wear / Heat / Corrosion Focus)

- High-load structural parts (load brackets, mounts, bases, load arms, shafts, threaded load-bearing features)

- Choose: Carbon/Alloy steels (e.g., 1045, 4140)

- Why: Higher strength, fatigue resistance, and wear resistance help reduce long-term deformation, looseness, and wear-out failure.When a failure can trigger safety risk or line downtime, steel is often “cheaper” in TCO because it reduces field failures and maintenance interventions.

- Corrosion-critical parts (outdoor cabinet hardware, coastal/humid connectors, chemical-environment supports)

- Choose: Stainless steel 304/316 (prefer 316)

- Why: Strong corrosion stability—especially in chloride exposure—reduces pitting/crevice-corrosion risk and lowers rework/replacement rates.In field-deployed equipment, corrosion resistance often matters more than unit price, because a single on-site replacement can cost far more than the material delta.

- High-temperature / hot-end structures (engine-adjacent brackets, hot-side fixtures, thermal-shock locations)

- Choose: Heat-resistant stainless (e.g., 310/321 per spec) / nickel-based alloys (per spec) or titanium alloys

- Why: Better strength retention and corrosion performance at elevated temperatures, avoiding stiffness loss or creep risk common to aluminum near its practical limits.If operating temperatures approach or exceed aluminum’s workable window, upgrading material becomes non-negotiable—no machining precision can compensate for long-term thermal instability.

- High-stiffness or vibration-sensitive components (precision bases, anti-vibration structures, positioning platforms)

- Choose: Steel or cast iron (depending on design/process)

- Why: Higher stiffness and damping help suppress vibration-driven dimensional drift and assembly misalignment.In precision positioning/metrology equipment, damping often drives repeatability more than weight reduction, so material selection directly affects usable accuracy.

Non-metal / Forming Alternatives (Cost-down / Insulation / Lightweight / High Volume)

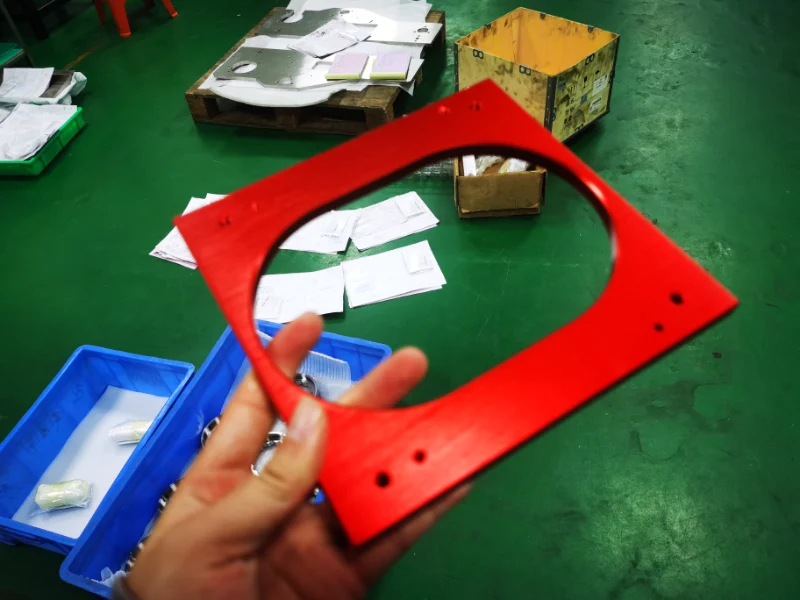

- Low-load structural & cosmetic parts (instrument housings, guards, covers, light-duty blocks)

- Choose: Engineering plastics—POM, PA (nylon), PC, ABS

- Why: Lower overall cost, lighter weight, and faster forming make them ideal when load requirements are modest but lead time matters.When the need is “coverage + assembly friendliness” rather than load-bearing, plastics shift cost from machining time to forming efficiency—especially effective for volume cost-down.

- High-temperature / chemical resistance / dimensional stability needs (fixture locating blocks, insulating parts, semiconductor fixtures, chemical-exposure parts)

- Choose: PEEK, PPS, PTFE

- Why: More stable under heat, chemicals, and clean environments, with better long-term dimensional retention than many commodity plastics.Although material price is higher, these polymers often lower total cost by reducing scrap, contamination risk, and unplanned downtime in high-stakes processes.

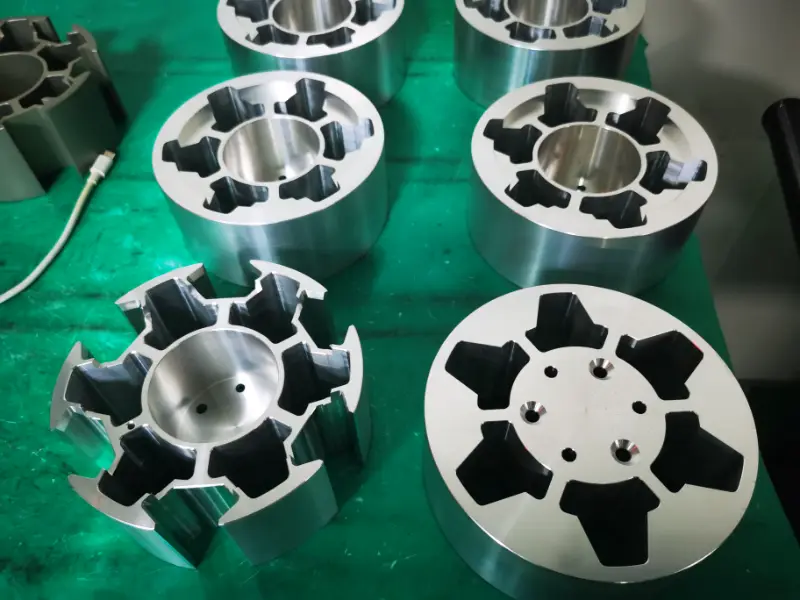

- High-volume, stable-geometry structural parts (housings, brackets, heatsink-like shapes, standardized enclosures)

- Choose: Aluminum/Zinc die casting or extrusions + secondary CNC

- Why: Lower unit cost and higher throughput when the design is stable and long-term supply is expected.Once volume is enough to amortize tooling, cost shifts from per-part machining hours to economies of scale—improving both pricing and delivery predictability.

- Extreme lightweight + high specific strength (special industries) (drones, sports equipment, ultra-light frames)

- Choose: Carbon fiber composites (CFRP)

- Why: Excellent strength-to-weight advantage for weight-critical designs.CFRP depends heavily on design, process control, and inspection (layup, hole-making, joint strategy), so it fits performance-driven programs more than fast-iteration, cost-constrained general parts.

How to choose surface Treatment

Procurement logic: decide the functional goal first—cosmetics, wear resistance, corrosion resistance, conductivity, weatherability, dimensional impact—then choose the most stable, scalable process that fits the alloy. Many issues (color variation, thickness stack-up, assembly interference) come from not addressing finishing effects upfront.

Bead blasting + anodizing (cosmetic + texture)

- Main function: improved appearance uniformity and premium texture; anodic film improves corrosion resistance and light scratch resistance.

- Most common alloys: 6061 and 6063 (better cosmetic outcomes and more stable color).

- Quality notes: define blast media and roughness range; define “A-surface” rules for masking and hanger marks.

Clear anodize / black anodize (general purpose, cost-effective)

- Main function: corrosion protection + consistent look; black anodize is common for optics/instrument glare reduction and general enclosures.

- Most common alloys: 6061 and 6063; 7075 can be used but requires tighter control on corrosion and film consistency.

- Quality notes: confirm color with a reference sample; specify whether threads/mating surfaces are masked or post-machined.

Hard anodizing (Hard Anodize, wear resistance)

- Main function: significantly higher surface hardness and wear resistance for sliding contact and frequent assembly.

- Most common alloys: 6061 is most common; 7075 is used in some projects with stricter corrosion/process control.

- Critical notes: thickness affects dimensions—plan tolerance compensation for critical bores/mating faces; hard anodize is a functional finish more than a “perfect cosmetic” finish.

Electroless nickel plating (functional, uniform coverage)

- Main function: corrosion resistance + wear resistance + very uniform coating; better coverage for holes/internal cavities; often easier to achieve stable electrical conductivity than anodizing.

- Most common alloys: 6061, 7075, 2024, especially for functional parts, wear areas, and critical mating surfaces.

- Quality notes: specify thickness range and dimensional impact; if grounding/conductivity matters, define electrical requirements or contact-point design.

Painting / powder coating (weatherability + color coverage)

- Main function: strong color coverage and outdoor durability; can hide minor substrate imperfections.

- Most common alloys: 6061, 6063, 5052, especially for housings, guards, and cabinets.

- Quality notes: coating thickness affects assembly—mask holes and mating surfaces; not ideal for precision mating parts where metallic texture or tight fits matter.

Procurement execution: what to request before placing the order (reduce rework and disputes)

To bring risk forward into the RFQ/PO stage, specify:

- Material certification: grade and temper (e.g., 6061-T6) + material reports when needed

- Key dimensions & GD&T: mark truly critical functional dimensions to avoid over-tightening the entire drawing

- Cosmetic standards: define A-surfaces, allowable defect boundaries, and color references (sample/swatches)

- Inspection & reports: whether CMM, roughness, coating thickness, corrosion testing, etc. are required

- Packaging & protection: aluminum scratches easily—packaging impacts yield at receipt

- Both parties agree to keep all CNC aluminum project information confidential and not disclose it to any third party without written consent.

Key point: many B2B disputes aren’t machining capability issues, but “acceptance criteria not defined.” Clear, executable requirements often reduce TCO more than aggressive unit-price negotiation.

Conclusion

The most effective cost-down move in CNC aluminum sourcing isn’t squeezing unit price—it’s defining material–tolerance–finish–inspection clearly at the RFQ stage so suppliers quote and deliver under the same assumptions, reducing rework, disputes, and lead-time risk at the source.