Copper CNC machining is widely used in industries that require excellent electrical conductivity, superior thermal performance, and reliable corrosion resistance. Compared with aluminum and bronze, copper offers outstanding functional advantages, but it is also one of the more difficult non-ferrous metals to machine due to its softness, high ductility, and strong tendency to adhere to cutting tools.

To achieve stable quality and cost-effective production, manufacturers must fully understand copper material behavior, physical properties, machining parameters, tooling strategies, and grade differences. This article provides a comprehensive technical guide to copper CNC machining, including cutting parameters, tool selection, copper grades, application fields, and detailed comparisons with aluminum and bronze.

Machining Characteristics of Copper

From a CNC machining perspective, copper is challenging not because it is hard, but because of its mechanical and physical behavior during cutting. Its high ductility causes material to smear rather than shear cleanly, while its softness increases the risk of built-up edge on cutting tools. In addition, copper forms long, continuous chips that are difficult to break and evacuate.

Copper also has extremely high thermal conductivity, which rapidly transfers heat away from the cutting zone. While this helps prevent overheating, it also reduces the localized thermal softening effect that assists cutting in other metals. As a result, copper machining requires sharp tools, stable feeds, and carefully optimized cutting parameters.

Key Physical Properties of Copper

Before defining machining strategy, it is essential to understand the core physical properties of copper that directly influence cutting behavior, tool wear, chip formation, and surface finish.

Copper Physical Properties (Typical Pure Copper)

| Property | Typical Value | Machining Relevance |

|---|---|---|

| Density | ~8.96 g/cm³ | High mass affects thin-wall stability |

| Thermal Conductivity | ~390–400 W/m·K | Rapid heat dissipation, cooler cutting zone |

| Electrical Conductivity | ~58 MS/m (≈100% IACS) | Primary reason for electrical applications |

| Hardness | ~35–50 HB | Very soft, prone to smearing |

| Elongation | >30% | High ductility, difficult chip breaking |

These properties explain why copper requires higher spindle speeds, sharper tools, lighter depths of cut, and stable finishing passes compared with many structural metals.

Copper CNC Machining Parameters

Spindle Speed (RPM)

Copper machining generally benefits from medium to high spindle speeds, which help reduce built-up edge and improve surface quality. Excessively low speed often leads to rubbing and material adhesion.

Typical reference ranges for solid carbide tools:

- Ø3–6 mm end mills: 10,000–18,000 RPM

- Ø6–12 mm end mills: 5,000–10,000 RPM

Feed Rate

Feed rate strongly influences chip thickness and surface integrity. Copper is sensitive to too-low feed, which causes friction instead of cutting.

Recommended feed per tooth:

- Roughing: 0.08–0.15 mm/tooth

- Finishing: 0.02–0.05 mm/tooth

Stable and continuous feed motion is especially important during finishing.

Depth of Cut

Because copper is soft and easily deformed, extremely aggressive depths of cut are not recommended.

Typical strategies:

- Axial depth of cut: 0.5–2.0 mm

- Radial depth of cut: 10–30% of tool diameter

High-speed, shallow-cut strategies are commonly used for precision copper components.

Tool Selection for Copper CNC Machining

Tool selection is one of the most critical success factors in copper CNC machining. Due to copper’s softness, high ductility, and strong adhesion tendency, improper tooling quickly leads to material smearing, built-up edge, poor surface finish, and unstable dimensional accuracy.

Key tooling principles include:

- Extremely sharp cutting edges:

Copper requires clean shearing rather than material deformation. Even slight tool wear can significantly degrade surface quality. - High rake angle geometry:

Positive rake angles reduce cutting force and improve chip flow, helping prevent adhesion and surface galling. - Polished flutes and chip grooves:

Polished tool surfaces reduce friction and minimize chip sticking, especially for high-purity copper grades. - Appropriate tool materials and coatings:

Solid carbide is the standard choice. Diamond-coated tools are suitable for high-volume or ultra-fine surface finish requirements. Hard coatings such as TiAlN are generally not recommended due to increased adhesion. - Low flute count (2–3 flutes):

Fewer flutes provide larger chip space, improving chip evacuation and process stability.

In practice, maintaining tool sharpness is more important than maximizing tool life when machining copper.

Machining Processes Suitable for Copper

Copper can be processed by many conventional and CNC machining methods. However, due to its softness, high ductility, and strong adhesion tendency, each process requires proper parameter and tooling control.

- CNC Milling:

Widely used for machining copper plates, heat sinks, cavities, and complex 3D shapes. High-speed milling with sharp tools and light cuts is preferred to avoid smearing and built-up edge. - CNC Turning (Lathe):

Suitable for shafts, bushings, rings, and rotational parts. Chip control and tool sharpness are critical because copper easily produces long, continuous chips. - Drilling:

Used for holes in busbars, plates, and components. Sharp drills with polished flutes are required to prevent chip welding and hole surface tearing. - Tapping and Thread Milling:

Threads can be machined in copper, but lubrication is strongly recommended to avoid galling and poor thread surface quality. - Boring and Reaming:

Used for high-precision holes. Light cutting and stable fixturing are required to avoid deformation and size variation. - Grinding and Polishing:

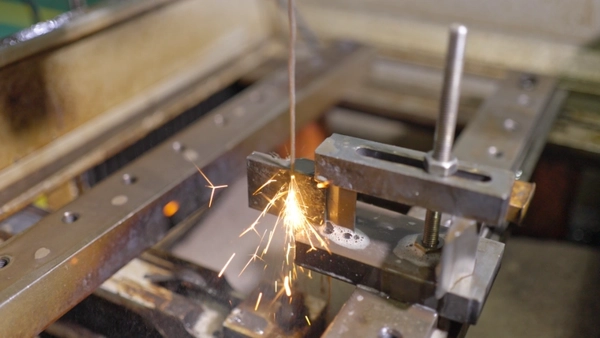

Often used as secondary processes to improve surface finish and meet high appearance or sealing requirements. - EDM (Electrical Discharge Machining):

Used for deep cavities, narrow slots, sharp internal corners, and complex features that are difficult or impossible to machine by conventional cutting tools.

In practice, milling and turning remain the main processes, while EDM is used as a complementary process for complex or high-precision features.

Climb Milling vs Conventional Milling in Copper Machining

Because copper is soft and has a strong tendency to stick to cutting tools, the choice between climb milling (down milling) and conventional milling (up milling) has a significant impact on surface quality, tool life, and dimensional stability.

Climb Milling (Down Milling)

Advantages:

- Better surface finish due to clean shearing instead of rubbing

- Less built-up edge and material adhesion

- Lower cutting force and more stable machining

- Strongly recommended for finishing and precision surfaces on copper

Disadvantages:

- Higher requirement for machine rigidity and workholding

- The cutter tends to pull the workpiece, which may cause vibration if fixturing is weak

Conventional Milling (Up Milling)

Advantages:

- Safer for rough surfaces, poor fixturing, or older machines

- Cutting force direction is more stable and less likely to pull the workpiece

Disadvantages:

- Worse surface finish on copper due to rubbing before cutting

- More heat, more adhesion, and more built-up edge

- Higher tool wear and lower surface quality

Common Copper Grades for CNC Machining (International Standards)

Commonly used copper grades include:

- C110 (ETP Copper): Excellent conductivity, poor machinability

The most commonly used high-conductivity copper, but difficult to machine due to strong adhesion and high ductility.

| Property | Typical Value | Machining Meaning | Recommended Tool & Requirement |

|---|---|---|---|

| Density | ~8.96 g/cm³ | Thin-wall parts are easy to deform | Rigid fixturing and low tool runout required |

| Electrical Conductivity | ~58 MS/m (~100% IACS) | Excellent electrical performance | — |

| Thermal Conductivity | ~390–400 W/m·K | Excellent heat dissipation | — |

| Hardness | ~40–50 HB | Very soft, high risk of built-up edge | Ultra-sharp solid carbide tools, high positive rake |

| Elongation | >30% | Extremely ductile, difficult chip breaking | 2-flute or single-flute polished tools, large chip space |

Tool Recommendation:

✅ Solid carbide, ultra-sharp cutting edge, high rake angle, polished flute

❌ TiAlN / AlTiN coatings are not recommended (increase adhesion)

- C101 (Oxygen-Free Copper): Ultra-high purity, very difficult to machine

The highest purity copper with the best conductivity, but the most difficult to machine among these three.

| Property | Typical Value | Machining Meaning | Recommended Tool & Requirement |

|---|---|---|---|

| Density | ~8.94–8.96 g/cm³ | Similar to C110 | Very rigid workholding required |

| Electrical Conductivity | ~58.5–59 MS/m (~101% IACS) | Slightly higher than C110 | — |

| Thermal Conductivity | ~400 W/m·K | Extremely high heat dissipation | — |

| Hardness | ~35–45 HB | Even softer than C110 | Only brand-new, extremely sharp tools |

| Elongation | >35% | Very high ductility, severe smearing risk | Single-flute or 2-flute mirror-polished tools |

Tool Recommendation:

✅ Solid carbide with mirror-polished flutes and extremely sharp edges

✅ PCD (diamond) tools for high-volume or ultra-fine surface finish

❌ Any “wear-resistant but not sharp” tools are not suitable

- C145 (Tellurium Copper): Improved machinability with good conductivity

Copper grade optimized for machining, offering a good balance between conductivity and machinability. The best choice for CNC machining.

| Property | Typical Value | Machining Meaning | Recommended Tool & Requirement |

|---|---|---|---|

| Density | ~8.94 g/cm³ | Similar to pure copper | Fixturing requirements are less critical |

| Electrical Conductivity | ~49–52 MS/m (~85–90% IACS) | Slightly lower but still very good | — |

| Thermal Conductivity | ~330–350 W/m·K | Slightly lower than pure copper | — |

| Hardness | ~70–90 HB | Much harder and more stable | Standard sharp solid carbide tools are sufficient |

| Elongation | ~10–20% | Much better chip breaking | 2–3 flute tools for aluminum/copper machining |

Tool Recommendation:

✅ Standard solid carbide end mills with sharp cutting edges

✅ DLC or ZrN coating can be used to extend tool life

⚠️ Heavy-duty steel-cutting tools are still not recommended

C145 is the most popular choice for CNC-machined copper parts that require a balance between performance and manufacturability.

Quick Tool Selection Summary

| Material | Machining Difficulty | Recommended Tool Type |

|---|---|---|

| C101 | ⭐⭐⭐⭐⭐ (Very difficult) | PCD or ultra-sharp mirror-polished carbide |

| C110 | ⭐⭐⭐⭐ | Ultra-sharp polished carbide |

| C145 | ⭐⭐ | Standard sharp carbide / DLC-coated |

One-Sentence Engineering Conclusion

C101 and C110 are “performance-first” copper grades, while C145 is a “machining-optimized” copper grade. For CNC machining, C145 is usually the best overall choice.

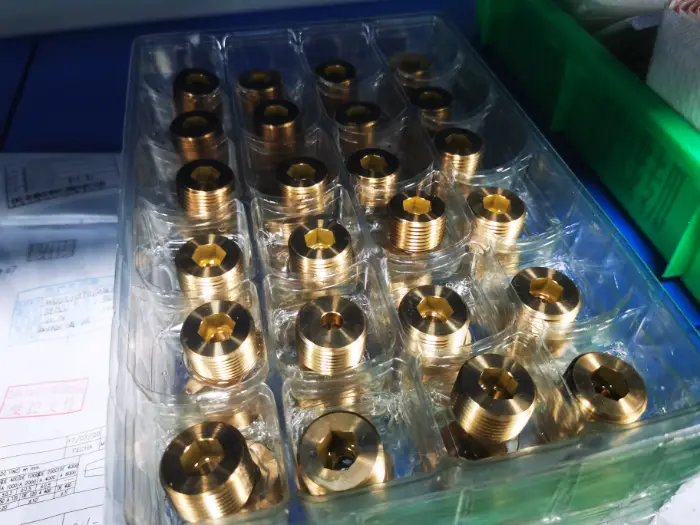

Applications of CNC Machined Copper Parts

CNC machined copper parts are mainly used in applications where functional performance outweighs machining efficiency.

Typical application areas include:

- Electrical power systems:

Busbars, terminals, and connectors rely on copper’s low electrical resistance to reduce energy loss and heat generation. - Thermal management:

Heat sinks, cooling plates, and heat spreaders use copper’s high thermal conductivity to efficiently dissipate heat. - Electronics and semiconductor equipment:

Precision copper components are widely used in vacuum systems, chip manufacturing equipment, and high-frequency devices. - RF and microwave components:

Copper housings and waveguides help minimize signal loss and electromagnetic interference. - Welding and industrial equipment:

Welding electrodes and conductive components benefit from copper’s combined electrical and thermal properties.

Aluminum as a Comparison Material in CNC Machining

Aluminum is considered one of the most CNC-friendly metals and is often used as a baseline comparison material.

Aluminum Physical Properties (6061 Reference)

| Property | Typical Value | Machining Relevance |

|---|---|---|

| Density | ~2.70 g/cm³ | Lightweight, ideal for high-speed machining |

| Thermal Conductivity | ~167–237 W/m·K | Good heat dissipation |

| Electrical Conductivity | ~35–38 MS/m | Moderate conductivity |

| Hardness | ~95 HB | Stable cutting behavior |

| Tensile Strength | ~290 MPa | Good strength-to-weight ratio |

Copper vs Aluminum CNC Machining: Pros and Cons

Copper and aluminum serve very different purposes in CNC machining: copper is performance-driven, while aluminum is efficiency-driven.

Copper – Advantages

- Much higher electrical and thermal conductivity, ideal for busbars, connectors, and heat sinks.

- Better performance in high-current and compact thermal designs.

- More stable electrical performance in demanding environments.

Copper – Disadvantages

- Poor machinability: sticky chips, tool adhesion, surface smearing.

- Lower production efficiency: slower speeds, lighter cuts, more finishing.

- Higher cost and much heavier than aluminum.

Copper vs Bronze CNC Machining: Pros and Cons

Copper and bronze serve different engineering purposes: copper is performance-driven, while bronze is durability- and machinability-driven.

Copper – Advantages

- Much higher electrical and thermal conductivity, ideal for electrical, thermal, and high-current applications.

- Better heat transfer performance for heat sinks, cooling plates, and conductive components.

- Preferred for functional parts where conductivity is the main requirement.

Copper – Disadvantages

- Poor machinability: soft, sticky, long chips, easy to smear.

- Lower dimensional stability during machining due to high ductility.

- Lower wear resistance and higher tool adhesion risk.

Additional Considerations in Copper CNC Machining

- Workholding must prevent deformation:

Copper is soft and easily deformed under clamping force. Fixtures should distribute pressure evenly and avoid localized stress, especially for thin-wall or precision parts, otherwise dimensional accuracy may be affected after unclamping. - Tool edges must be kept extremely sharp:

Copper relies on clean shearing rather than compressive cutting. Even slightly worn tools will cause smearing, tearing, and built-up edge, leading to poor surface finish and unstable dimensions. - Coolant or mist lubrication reduces adhesion:

Copper has a strong tendency to stick to cutting edges. Proper coolant or mist lubrication helps reduce friction, prevents chip welding, and improves both surface quality and tool life. - Finishing passes and polishing may be required:

Due to copper’s ductility, it is difficult to achieve perfect surface quality in roughing. Light finishing passes and, if necessary, secondary polishing are often used to meet tight tolerance and surface finish requirements.

Conclusion

Copper CNC machining is essential for high-performance electrical and thermal applications, despite its machining challenges. By understanding copper’s physical properties, selecting the correct grade, and optimizing cutting parameters and tooling strategies, manufacturers can achieve excellent dimensional accuracy and surface quality. Compared with aluminum and bronze, copper remains the preferred material when conductivity and thermal performance are the primary requirements.