In the automotive parts manufacturing industry, cost control has never been merely a purchasing activity, but rather a systematic engineering issue. Whether it is chassis parts, housings, shafts, bushings, or plastic interior structural parts, even if a single part is reduced by only a few cents, it will be amplified into a huge cost advantage over the entire vehicle lifecycle.CNC machining, due to its high precision, good stability, and strong adaptability, is widely used in sample making, small-batch, and medium-batch production of automotive parts. However, many purchasing and engineering personnel will find that: seemingly similar parts can have very large quotation differences among different factories.This is exactly because: Automotive CNC Machining Cost is not simply “working hours × unit price”, but a comprehensive cost jointly determined by design, process, quality, precision requirements, and equipment system.

What is Automotive CNC Machining?

Automotive parts CNC machining refers to a manufacturing method that uses CNC machine tools (CNC machining centers, mill-turn machines, CNC lathes, etc.) to perform high-precision and high-consistency machining on automotive metal or engineering plastic parts.

Typical applications include:

Chassis structural parts, brackets, connecting parts

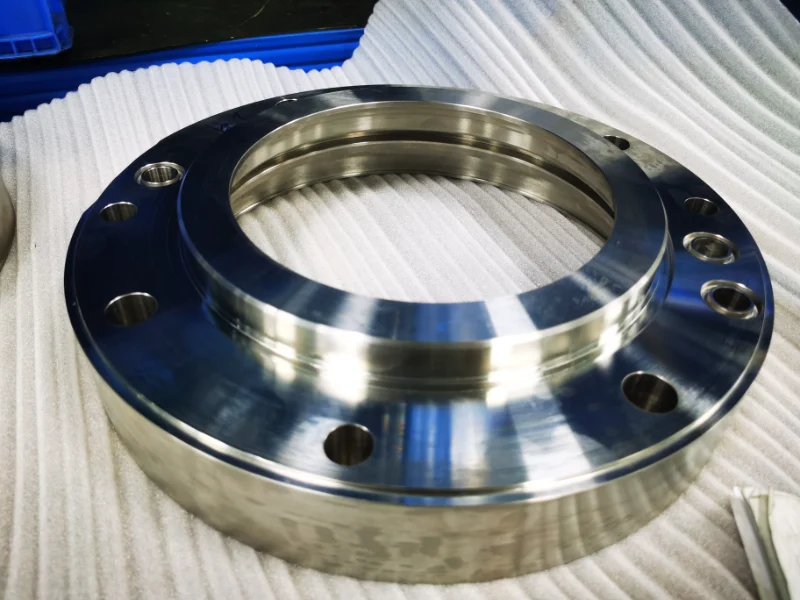

Various housings (motor housings, gearbox housings, pump housings, etc.)

Shaft parts, bushings, liners, sleeve-type parts

Plastic interior frames, support structural parts, buttons, knobs

Various functional mounting surfaces, sealing surfaces, and mating surface parts

CNC machining in the automotive industry mainly undertakes:

Sample prototyping, ramp-up before mass production, small and medium batch production, precision interface surface machining, and other key roles.

Symmetrical structures can be quickly produced by CNC turning. Parts with complex structures require manual milling machines or precision three-axis or five-axis CNC machines for precision milling. Symmetrical parts such as shaft parts, bushings, and sleeve parts have a significantly higher machining speed than milled precision-formed parts.

What parts does automotive CNC machining cost consist of?

A professional automotive parts CNC quotation usually includes the following parts:

Programming cost :

Professional programmers set machining programs and steps according to the received drawings and dimensional requirements, as well as notes on machining parameter settings (marking of spindle speed / feed rate / drilling depth and speed).

Fixture and tooling cost :

Workpieces with special structural dimensions or relatively soft engineering plastic materials need to consider possible vibration and displacement during machining. Most of them need to pre-make fixtures corresponding to the machining shape and material requirements to ensure smooth milling.

Machine machining cost :

Simple-structure single-face milling can use manual milling machines for fast machining. Compared with three-axis / four-axis / five-axis CNC machining, this can greatly reduce the unit time machining cost. For symmetrical bushing-type parts, lathes can be used for fast machining. Complex multi-face structural feature parts need multi-axis CNC machining for precision milling or drilling and tapping processes.

Tooling and tool wear cost :

Cast iron, aluminum alloys, and other metals can be machined using diamond / coated carbide milling cutters; stainless steel, alloy steel, hardened steel, and titanium alloy materials mostly require relatively expensive tools such as ultra-fine grain carbide / CBN / PCD coating / ceramic tools for milling in order to complete machining.

ABS / PP / PE / POM and other materials can use relatively inexpensive ordinary carbide tools to remove excess material; PA / PC / PMMA / PEEK / PPS / glass fiber reinforced plastics require polished-edge carbide, diamond, or PCD-coated carbide tools to effectively overcome difficult machining problems such as material stringing, easy melting, easy cracking, and high hardness and rigidity.

Inspection and quality cost :

Sampling inspection can reduce time cost. Full inspection greatly increases the required time, and the cost naturally increases. It is recommended to adopt sampling inspection plus key feature inspection, which can greatly reduce machining cost.

Management and manufacturing cost :

Standardized processing system parks require systematic and standardized management. Compared with small workshop-style CNC machining, the cost will be slightly higher, but it can greatly reduce the occurrence of defect rate and production disputes. At the same time, there are dedicated personnel for coordination and reliable services such as meetings and remote adjustment and optimization, which can better help the precision machining of automotive parts.

Defect rate and risk cost :

Parts with high machining tolerance and precision requirements will have a 3–10% defect rate during final inspection, so this part of loss will also increase the machining quotation. This can be improved by professional and reliable engineers conducting discussions before machining and “loosening” non-essential machining feature requirements.

How is Automotive CNC Machining Cost usually calculated?

Inside the factory, the following logic is usually adopted:

Total cost = (machine cycle time × hourly rate) + (labor / auxiliary time) + (tool consumption) + (fixture amortization) + (quality cost) + (management cost)

Among them:

Simple parts: the main cost lies in machine time

Complex parts: the main cost lies in the number of setups, setup time, and quality control

Small batches: engineering and fixture amortization account for a very high proportion

Large batches: cycle time and stability determine the cost

This is also why:

The unit price difference between 1 piece, 100 pieces, and 1000 pieces may be several times or even more than ten times.

Common automotive precision CNC machining application scenarios

CNC in the automotive industry is mainly used for the following types of parts:

Chassis system: brackets, mounting seats, steering structural parts

Power system: housings, end covers, pump bodies, functional interface parts

Transmission system: shafts, bushings, splines, liners

New energy: motor housings, battery structural parts, cooling system parts

Interior structures: plastic frame parts, support parts, mounting bases

The common characteristics of these parts are:

Either the structure is complex, or the precision requirements are high, or long-term stable consistency is required.

Main factors affecting Automotive CNC Machining Cost

Material type (aluminum, steel, copper, stainless steel, cast iron, plastics):

Aluminum, cast iron, and ordinary plastics such as POM and ABS have lower costs. Brass, bronze, stainless steel, and PEEK, PMMA, glass fiber, carbon fiber, and other composite engineering plastics have higher raw material costs.

Structural complexity (thin walls, deep cavities, multi-face machining):

Too thin wall thickness and complex deep cavity structures easily lead to workpiece cracking or tool failure problems. Multi-face machining, under the premise of needing to change fixtures, easily causes assembly errors. The workpiece can be divided into two or more structures for machining and then welded and assembled, which can greatly improve machining efficiency and reduce scrap rate.

Tolerance and geometric tolerance requirements:

Excessively high tolerance requirements and unnecessary geometric tolerance feature requirements need higher machine tool operation to achieve, and at the same time easily increase the scrap rate. It is possible to appropriately reduce the machining accuracy tolerance requirements of non-essential groove holes and other features, improve work efficiency, and reduce the production cost per piece.

Number of setups and process route:

Try to minimize fixture changes and workpiece posture adjustments. Simple workpieces use three-axis for fast machining. Complex multi-section parts can use four-axis or five-axis machines for machining. At the same time, after five-axis machining of feature surfaces, EDM cutting / three-axis machining can be added to remove excess material, which can greatly reduce five-axis machining time, effectively reduce cost, and improve workpiece surface finish.

Batch size:

The machining cost of samples is usually high. As the quantity increases, the machining cost per piece can be greatly reduced.

Automation level:

Efficient and precise machining machines can greatly reduce manual intervention time, effectively ensure the surface finish of automotive parts, and reasonably reduce manual participation in the machining process, which can better reduce costs.

Quality system requirements:

ISO and other quality system certification certificates, combined with commonly used tolerance grades in the industry for machining, can well control the cost of automotive parts.

10 practical methods to reduce automotive CNC machining cost

Consider DFM (manufacturability) at the design stage

Avoid unnecessary ultra-high precision tolerances

Avoid high-cost structures such as deep and narrow slots, deep cavities, small R corners

Use conventional materials and commonly used tool specifications

Reasonably combine milling, turning, and EDM processes to reduce the number of setups

Try to unify datums and reduce tolerance chain control cost

Reasonably increase batch size to dilute the cost of single-part production and fixture customization

Consider automated machining for mature parts

Avoid frequent changes to design parameters

Let the machining manufacturer participate early in process optimization and machining program simplification

In reality, 30%–70% of the machining cost of many parts is actually “designed”.

How to choose a cost-effective automotive CNC machining service provider?

A qualified automotive parts CNC supplier should have:

Engineering capability

Be able to understand the functional relationship behind the drawings: be able to understand the functional feature areas that customers care about,

Be able to propose DFM and cost optimization suggestions, and communicate and optimize difficult-to-machine areas in time.

Equipment capability

Reasonable configuration of 3-axis / 4-axis / 5-axis / mill-turn / EDM / CNC grinding and other processes

It is better to have automation or batch machining experience, to avoid your automotive parts being transferred and processed among multiple factories, causing unexpected losses and increasing machining time cost.

Quality system

At least have: ISO9001 / IATF16949

Have PPAP, CPK, SPC experience

Cost logic

The quotation is not random, and can explain the cost composition and roughly interpret the machining cost of machining features

Can provide cost reduction paths and optimized design suggestions as the batch size changes.

Industry experience

It is better to have done chassis parts / housings / shafts / structural parts / engine blocks

Understand the rhythm and ramp-up rules of automotive projects

Conclusion

Automotive CNC machining cost is never simply a matter of price negotiation, but the result of systematic engineering decisions. From part design, material selection, structural complexity, tolerance definition, process planning, equipment configuration to supplier capability, every step directly determines the final manufacturing cost. In practice, 30% to 70% of machining cost is already “designed in” at the early stage. Only by combining good design, proper process planning, stable manufacturing systems and capable suppliers can companies achieve long-term, sustainable cost optimization instead of short-term price cutting.