In the metalworking industry, Electrical Discharge Machining (EDM) is widely used for precision processing, such as mold manufacturing and processing complex-shaped components. Both fast wire cut EDM (Wire Cut EDM) and slow wire cut EDM (Slow Wire Cut EDM) are two important types of EDM, each with its unique advantages and application scenarios. This article will compare these two technologies in detail from multiple dimensions, including working principles, electrode wire, coolant, processing speed, accuracy, surface quality, cost, application scenarios, processing considerations, and alternative technologies.

Working Principles of Fast vs Slow Wire Cut EDM

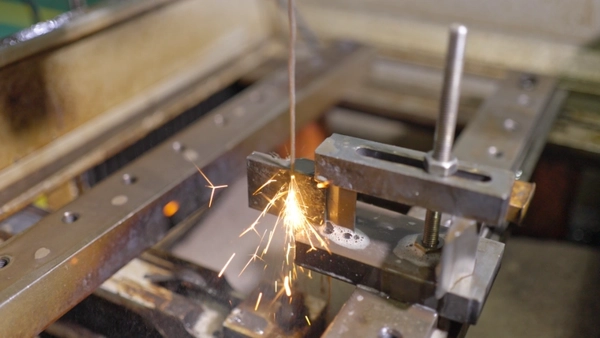

Fast Wire Cut: Fast wire cut EDM works by using high-frequency electrical discharges between the electrode wire and the workpiece surface to convert electrical energy into thermal energy, vaporizing, gasifying, or melting the metal to complete the cutting. Since the electrode wire is thicker and the current is higher, it can quickly perform cutting tasks for thicker materials, but at the cost of precision and surface quality.

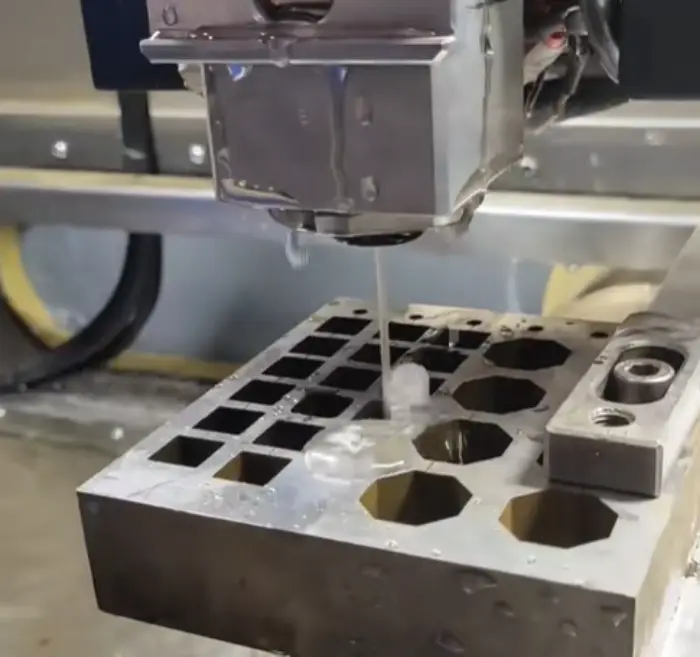

Slow Wire Cut: Slow wire cut uses smaller currents and finer electrode wires. The cutting speed is slower, but it allows for more detailed electrical discharges for precise cutting. Slow wire cut emphasizes high-precision processing and is suitable for tasks that require extremely high surface quality and dimensional tolerances.

Electrode Wire Comparison

Fast Wire Cut: Fast wire cut typically uses thicker electrode wires (0.2-0.25mm), suitable for quickly cutting thicker metal materials. While thicker electrode wires increase cutting efficiency, they also result in larger cutting marks and lower processing accuracy.

Slow Wire Cut: Slow wire cut uses finer electrode wires (0.03mm~0.15mm). The finer wire reduces the discharge area during the cutting process, thus improving precision and surface quality. Fine electrode wires effectively reduce surface roughness.

Electrode Wire Materials Comparison

Electrode wires play a crucial role in EDM, directly affecting machining accuracy, surface quality, cutting efficiency, and electrode wire lifespan. The materials used for electrode wires differ between fast and slow wire cuts. Common electrode wire materials include copper, copper alloys, molybdenum, and brass.

Copper/Brass Electrode Wire

Copper electrode wires are one of the most commonly used materials in EDM, with good oxidation resistance and used in slow wire cut processing.

Excellent Electrical and Thermal Conductivity: Copper wire has excellent electrical conductivity and thermal conductivity, optimizing discharge performance and ensuring stable cutting.

One-Time Use: Copper wire is used once for each processing cycle, with a wire diameter precision of ±0.001mm, suitable for medium to high-precision processing.

Wide Adaptability: It is suitable for processing a wide range of metal materials, including carbon steel, stainless steel, aluminum alloys, and copper alloys, especially for regular batch production with lower precision requirements.

Mechanical Strength: Copper wire has a tensile strength of approximately 600 MPa, which is sufficient to maintain stable tension during the cutting process. While its tensile strength is lower than that of molybdenum wire, copper wire can still ensure good processing stability in the lower-tension operation of slow wire cut EDM, preventing wire breakage or vibration.

Molybdenum Electrode Wire

Molybdenum electrode wires are commonly used in precision processing due to their high melting point and strength, particularly in fast wire cut processing.

High Melting Point and High Tensile Strength: Molybdenum wire has a melting point of 2610°C and tensile strength of approximately 1000 MPa, making it suitable for high-temperature, high-tension conditions in fast wire cut EDM.

Cycle Use: Molybdenum wire can be used 5-10 times in repetitive cycles, providing cost-effectiveness for rough and semi-fine processing.

Strong Adaptability: It is ideal for processing materials such as carbon steel, stainless steel, and hard alloys, and can be used in fast wire cut EDM for medium-thick workpieces (up to 300mm).

High Processing Speed: Molybdenum wire offers fast processing efficiency, especially for high-speed rough cutting, making it suitable for regular precision requirements.

Tungsten wire

Extremely High Melting Point : Tungsten has a melting point of 3410°C, making it highly resistant to erosion in high-temperature environments, ensuring minimal wear during the cutting process.

High Tensile Strength : With a tensile strength of ≥1500 MPa, tungsten wire remains stable under high tension, preventing wire breakage and vibration during the cutting process.

Excellent Rigidity : Tungsten wire maintains high rigidity, even at ultra-fine diameters (0.02mm), making it ideal for ultra-fine micro-grooves and micro-holes that are difficult to achieve with other wires.

Resistance to High-Temperature Erosion : Tungsten wire resists high-temperature erosion effectively, allowing it to handle pulse discharge temperatures up to 8000–10000°C without significant wear, making it suitable for extreme cutting conditions.

The following is a summary and comparison of the three types of electrode wires.

| Electrode Type | Copper Wire (Brass/Galvanized/Pure Copper) | Molybdenum Wire (Standard Mo2) | Tungsten Wire (Pure Tungsten/Tungsten Alloy) |

|---|---|---|---|

| Applicable Machine | Exclusive for WEDM-LS (Low-Speed Wire EDM) | Exclusive for WEDM-HS (High-Speed Wire EDM) | Occasional use for WEDM-HS / Special working conditions for high-end WEDM-LS |

| Core Characteristics | Excellent electrical/thermal conductivity, melting point 1083℃, low wear | Melting point 2610℃, recyclable, moderate tensile strength | Melting point 3410℃, highest tensile strength, nearly no wear, high rigidity of ultra-fine wire |

| Machining Accuracy | ±0.005~0.01mm | ±0.01~0.02mm | Within ±0.001mm |

| Surface Roughness | Ra0.2~1.6μm | Above Ra3.2μm | Below Ra0.2μm |

| Usage Mode | Disposable | Recyclable for 5~10 times | Disposable (for special working conditions) |

| Application Scenario | Routine/high-precision machining of WEDM-LS (molds, precision parts) | Rough/semi-finish machining of WEDM-HS (general molds, batch parts) | Machining of ultra-thick workpieces, ultra-fine grooves, super-hard brittle materials |

| Cost Level | Medium-High | Extremely Low | Extremely High |

| Core Label | Standard for WEDM-LS, high precision/high finish | Standard for WEDM-HS, low cost/high efficiency | Special electrode, for difficult machining only |

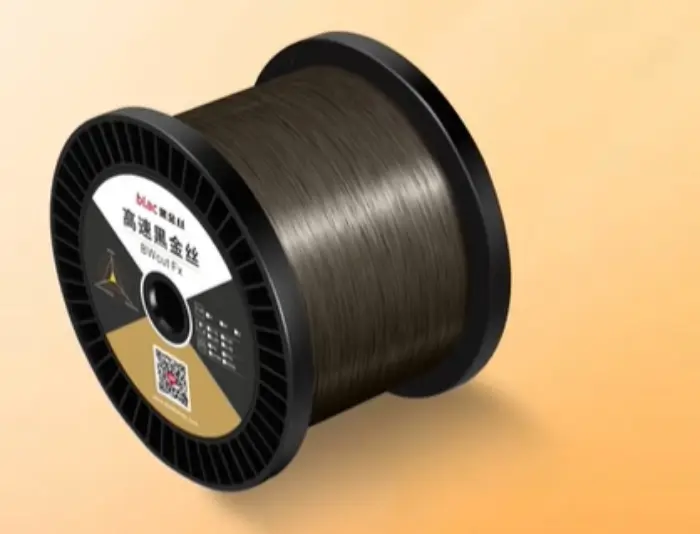

Black Gold Wire – new design wire for edm machining

Black Gold Wire is a high-performance composite electrode wire exclusively used for slow wire EDM. It is commonly referred to as “Black Wire” or “Black Gold Coated Wire” in the market. The core is typically made of high-tensile brass, with a special alloy coating on the outer layer (such as zinc-nickel, cobalt alloy, or diamond-like carbon coatings), giving it a black-gray or matte black-gold appearance. It is considered a more advanced model than ordinary zinc-coated wire.

- Higher tensile strength compared to regular zinc-coated wire, making it suitable for cutting thick, high-tensile materials.

- More stable discharge, with lower wire breakage rate, reduced wear, and faster cutting speed.

- The coating suppresses arcing, improves chip removal, and provides better surface finish and accuracy than regular zinc-coated wire.

- Used exclusively for slow wire EDM, for one-time use. It is more expensive than regular zinc-coated wire but cheaper than pure tungsten wire.

- Positioned as a high-end production wire, between ordinary zinc-coated copper wire and special tungsten wire.

Coolant’s Role and Requirements

Fast Wire Cut: In fast wire cut EDM, the choice of coolant is crucial because cutting generates a significant amount of heat. Typically, an emulsified oil coolant is used. It provides excellent cooling, quickly removing heat generated during cutting, preventing overheating and deformation of the workpiece. Additionally, emulsified oil offers some lubrication, reducing friction between the electrode wire and the workpiece, thus extending the lifespan of the electrode wire. The cleaning function of the coolant also helps remove cutting debris, maintaining the stability of the discharge process, thereby improving processing efficiency and surface quality.

Slow Wire Cut: In slow wire cut EDM, coolant choice is more focused on precision processing requirements, typically using deionized water or kerosene. Deionized water has extremely low electrical conductivity and contains no ions, avoiding electrolysis and ensuring stable electrical discharges. It provides good cooling, effectively removing heat generated during cutting and preventing overheating or oxidation on the workpiece surface. At the same time, deionized water has strong cleaning capabilities, helping to remove cutting debris, reduce electrode wire wear and contamination, ensuring the stability of high-precision processing and surface quality.

Processing Speed Comparison

Fast Wire Cut: Fast wire cut has a faster cutting speed, with linear processing speeds ranging from 8 to 10 meters per second, making it suitable for mass production or tasks that require quick turnaround. It can quickly complete cutting of thicker metal materials, giving it a significant advantage in production efficiency.

Slow Wire Cut: Slow wire cut has a slower processing speed, with linear processing speeds less than 0.2 meters per second. It is ideal for high-precision and complex shape processing. Due to its slower cutting speed, it requires more processing time and is suited for high-precision machining and small-batch production.

Processing Accuracy and Surface Quality Comparison

Fast Wire Cut: Since fast wire cut uses thicker electrode wires and higher currents, although it can complete cutting quickly, it leads to larger discharge areas, resulting in lower precision. Typical machining accuracy is ±0.02mm to ±0.08mm, with surface roughness typically ranging from Ra 3.0μm to 4.0μm. Post-processing techniques such as grinding are usually required to improve surface quality.

Slow Wire Cut: Slow wire cut, with its finer electrode wires and low-current discharge characteristics, achieves higher machining accuracy and surface quality. Its machining accuracy can reach ±0.002mm to ±0.01mm, and surface roughness can range from Ra 0.2μm to 0.8μm. Since slow wire cut has a smaller heat-affected zone, surface smoothness is higher, requiring almost no subsequent processing. If very high surface smoothness is needed, CNC grinding can further improve the surface finish.

Working Environment Requirements Comparison

Fast wire cut EDM has relatively relaxed temperature requirements, typically operating within a range of 10°C to 30°C. Although the temperature is not strictly controlled, it is still important to maintain it within a reasonable range to avoid issues with coolant stability and smooth cutting processes during high-volume cutting tasks.

In contrast, slow wire cut EDM has much stricter temperature requirements for its working environment. To ensure high-precision processing, slow wire cut requires a constant temperature environment, with the temperature controlled between 20°C and 26°C. Temperature fluctuations can lead to slight errors during the workpiece processing, which would affect the accuracy and surface quality, making a stable temperature critical for slow wire cut operations.

Electrode Wire Feeding Method Comparison

In fast wire cut EDM, the electrode wire feeding method is usually manually assisted. Since fast wire cut has higher cutting speeds and thicker electrode wires, manual feeding is more adaptable to rapid processing and larger-sized workpieces.

In slow wire cut EDM, the electrode wire feeding method is automated. The automated feeding method ensures that the electrode wire enters the cutting area precisely, minimizing errors during manual operation, which is essential for high-precision and long-duration stable processing.

Electrode Wire Usage Comparison

Fast wire cut EDM typically uses molybdenum wire for electrode wires due to its high melting point and strength, allowing it to work stably under high temperatures. Molybdenum wire can be reused, but it experiences wear during use, so it needs to be regularly checked for wear and replaced when necessary to ensure cutting effectiveness and precision.

On the other hand, slow wire cut EDM uses copper wire for its electrode wire. Copper wire is typically for one-time use, meaning it needs to be replaced with a new electrode wire after each workpiece is processed. Copper wire is prone to wear and oxidation during cutting, and to ensure high precision and surface quality, one-time-use copper wire is typically used to minimize errors and improve accuracy.

Cost Comparison

Fast Wire Cut: Fast wire cut has lower production costs, mainly in terms of equipment purchase cost, consumables (electrode wire) costs, and labor costs. Due to its fast cutting speed, it is suitable for mass production, resulting in a lower overall cost. Therefore, fast wire cut is ideal for non-precision cutting tasks where cost is a critical factor.

Slow Wire Cut: Slow wire cut has higher costs, with more expensive equipment and electrode wire costs, as well as longer processing times, leading to higher labor costs. While the unit cost of slow wire cut is higher, it is suitable for high-end markets that require high precision, such as precision mold processing and aerospace industries.

Application Field Comparison

Fast Wire Cut: Due to its fast processing speed and lower cost, with labor costs ranging from $10 to $50 per hour, fast wire cut is suitable for mass production, mold manufacturing, cutting thicker metals, and automotive parts. It is mainly used for cutting parts that do not require stringent precision.

Slow Wire Cut: Slow wire cut is suitable for tasks that require extremely high precision, with labor costs ranging from $30 to $200 per hour. It is widely used in precision mold manufacturing, medical equipment, aerospace, high-precision components, and complex shape cutting. It is ideal for tasks requiring high surface quality and small dimensional tolerances.

Processing Considerations and Solutions

Fast Wire Cut Processing Considerations:

- Electrode Wire Wear: Fast wire cut uses thicker electrode wires and higher currents, which can cause faster wear or breakage. Therefore, it is important to regularly check the condition of the electrode wire and replace it in a timely manner. Using more wear-resistant electrode wire materials or optimizing current intensity during the cutting process can help reduce wear.

- Surface Roughness: Larger surface roughness may occur after cutting. This can be improved by adjusting the cutting speed, optimizing the current, and the electrode wire diameter. Increasing the coolant flow also helps reduce thermal effects.

- Coolant Management: Since cutting generates a large amount of heat, effective coolant use is critical. Ensuring sufficient cooling helps prevent overheating and maintains stable processing.

Slow Wire Cut Processing Considerations:

- Heat Deformation Control: Slow wire cut has lower current and finer electrode wires, reducing heat deformation. However, it still requires control over the heat generated during processing. This can be achieved by optimizing coolant usage (e.g., using deionized water) and reducing cutting current to minimize heat accumulation and ensure processing accuracy and workpiece quality.

- Electrode Wire Wear/Pollution: Deionized water can reduce ion and impurity interference. Regular electrode wire replacement is necessary to maintain good conductivity.

- Cutting Speed: Slow wire cut processes more slowly, requiring longer production cycles. Adjusting cutting parameters, using appropriate electrode wire diameters, increasing discharge frequency, and reducing excessively long cutting paths can help improve processing efficiency.

Alternative Technologies Comparison

Alternative Technologies for Fast Wire Cut:

- Laser Cutting: Suitable for rapid cutting, especially for complex-shaped metals, but inferior to slow wire cut in surface quality and cutting precision.

- Waterjet Cutting: Suitable for cutting most metals and non-metals. Waterjet offers better cutting precision but is slower and not suitable for very thick materials.

Alternative Technologies for Slow Wire Cut:

- Laser Processing: Laser processing offers similar high precision and surface quality as slow wire cut but is more expensive in terms of equipment and maintenance costs.

- Electroforming or Precision Casting: For some high-precision parts, electroforming or precision casting is a viable alternative, though it is less flexible and not suitable for all cutting applications.

Comprehensive Comparison and Selection Suggestions

In summary, both fast wire cut and slow wire cut have their advantages and limitations. When choosing the appropriate processing method, users should consider the specific processing task requirements, product specifications, and budget:

- Fast Wire Cut is suitable for:

- Rapid processing speed and lower cost for mass production.

- Cutting thick metals or non-precision parts.

- Tasks that do not have stringent requirements for surface roughness or precision.

- Slow Wire Cut is suitable for:

- High precision, high surface quality parts.

- Precision mold manufacturing, complex shape cutting, aerospace, and medical equipment.

- Small-batch, high-value-added products.

In actual applications, many factories choose a combination of fast wire cut and slow wire cut based on the specific characteristics of the workpiece to maximize production efficiency and product quality.

Summary Table for Fast Wire Cut vs. Slow Wire Cut

| Comparison Item | Fast Wire Cut | Slow Wire Cut |

|---|---|---|

| Working Principle | High-frequency electrical discharges, thicker electrode wire, larger current, suitable for rapid cutting | Low current discharge, finer electrode wire, focuses on high-precision processing |

| Electrode Wire Diameter | 0.2-0.25mm | 0.03mm-0.15mm |

| Electrode Wire Material | Molybdenum Wire | Copper Wire |

| Coolant | Emulsified oil | Deionized water / kerosene |

| Processing Speed | Fast, suitable for mass production | Slower, suitable for high-precision, small-batch processing |

| Processing Accuracy | ±0.02mm to ±0.08mm | ±0.002mm to ±0.01mm |

| Surface Quality | Ra 3.0μm to 4.0μm | Ra 0.2μm to 0.8μm |

| Cost | Lower, suitable for mass production | Higher, suitable for precision processing |

| Application Areas | Mold manufacturing, mass production, cutting thick metals, automotive parts | Precision mold manufacturing, high-precision components, small-batch production |

Conclusion

Through a detailed comparison of fast and slow wire cut EDM technologies, it’s clear that each has distinct advantages in terms of processing speed, accuracy, surface quality, cost, and application fields. Fast wire cut is ideal for high-volume production and tasks that don’t require high precision, thanks to its fast cutting speed and lower costs. On the other hand, slow wire cut excels in precision and surface quality, making it suitable for high-precision parts in industries like mold manufacturing and aerospace. Users should choose the appropriate technology based on specific processing needs, product accuracy requirements, and budget. By effectively combining both methods, manufacturers can enhance overall productivity while maintaining a balance between product quality and cost efficiency.