In the process of transitioning products from the research and development stage to large-scale mass production, selecting the appropriate manufacturing process is one of the key factors that determines whether a project succeeds or fails. High-standard production processes directly determine component performance and long-term operational stability. High volume CNC machining has higher production standards and assembly stability in terms of production scale, material requirements, and complex feature machining capability.

What Is High Volume CNC Machining?

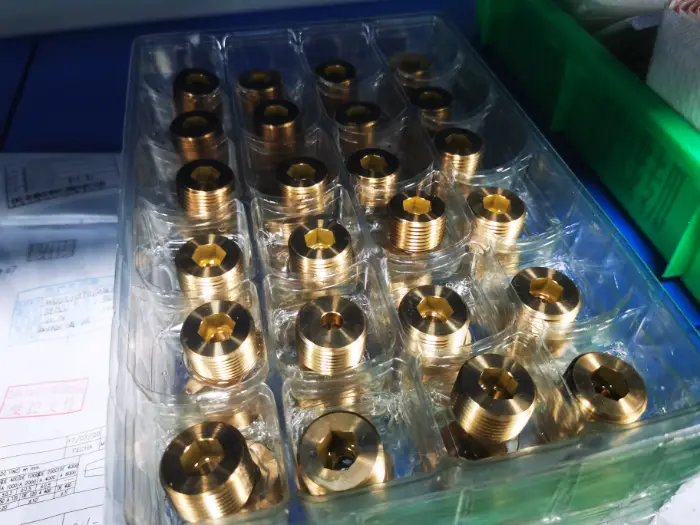

High volume CNC machining is a subtractive manufacturing process that performs cutting operations on batch workpieces using computer numerical control equipment. This process is widely used in precision component production ranging from medium to high volumes. The production process includes CNC milling, turning, surface grinding (cylindrical grinding), tapping, wire cutting, surface finishing, and other operations.

Unlike mold-based manufacturing processes, CNC machining usually does not require expensive mold investment, therefore providing greater flexibility in product design iteration and multi-variant production.

Main Advantages of High Volume CNC Machining

High dimensional accuracy and stable repeatability

As long as machining tools, cutting heads, and machine precision are properly maintained and replaced during batch CNC production, high precision standards and consistency can be maintained from the first component to the last workpiece (accuracy tolerance level of 0.005–0.01mm). According to milling conditions, replacing tools in a timely manner can ensure machining features meet precision requirements and significantly reduce defect rates.

Low mold investment cost

Directly bypasses mold design, sampling, and optimization stages, greatly saving production line time and cost.

Strong design modification flexibility

Drawing features and tolerance requirements can be adjusted promptly, reasonably reducing production difficulty, time cost, and machining cost.

Applicable to metals and engineering plastics

Strong adaptability to different materials. By selecting appropriate coated cutting tools, setting proper spindle speed and feed method, it can effectively handle machining challenges such as high hardness, brittleness, burr formation, and chip removal pressure.

Short production startup cycle

Once production quantity is determined, typically from hundreds to thousands of units, and the most efficient machining workflow is confirmed (integrating CNC milling, wire cutting, grinding, manual milling, etc.), production can be immediately deployed onto the production line for organized machining.

However, when the number of components reaches tens of thousands in extremely large production volumes, CNC machining usually has a longer per-part machining cycle compared to mold-based processes.

Alternative High-Volume Production Processes

Although CNC machining has high versatility, under specific production quantity requirements, injection molding and die casting processes often provide more cost-competitive solutions.

Injection Molding: Mainstream Solution for Plastic High-Volume Production

Injection molding forms components by injecting molten plastic into steel molds. Once mold development is completed, injection molding can achieve extremely high production efficiency and extremely low per-unit cost.

Injection Molding Advantages

- Ultra-low per-part cost (large-scale production)

- Stable and aesthetically consistent surface quality

- Extremely high production efficiency

- Capability to manufacture complex plastic structures

Injection Molding Limitations

- High initial mold investment cost

- Material selection mainly limited to plastics

- High design modification cost after mold completion

- Long early-stage project development cycle

Injection molding is highly suitable for manufacturing plastic products with stable design and extremely large production volumes.

Die Casting Process: Efficient Solution for Metal Batch Production

Die casting is a process that forms components by injecting molten metal into steel molds under high pressure, mainly applied to aluminum alloy, zinc alloy, and magnesium alloy component production.

Die Casting Process Advantages

- High production efficiency

- Good dimensional consistency

- Reduced secondary machining requirements

- Suitable for metal high-volume manufacturing

Die Casting Process Limitations

- Higher mold investment cost

- Limited alloy material selection

- Lower design flexibility after mold completion

- High-precision areas may still require secondary CNC machining

Manufacturing Cost Comparison

Production cost is usually the core factor determining manufacturing process selection. The following shows common industry cost range references.

Tooling Cost Comparison

| Process | Tooling Cost Range |

|---|---|

| CNC Machining | $0 – $2000 |

| Injection Molding | $2,000 – $80,000+ |

| Die Casting Process | $3,000 – $60,000+ |

CNC machining has the lowest initial investment, while mold-based processes require higher upfront investment but lower unit cost in large-scale production.

Per-Part Production Cost Comparison

CNC Machining Unit Price Range

| Material | Per-Part Price |

|---|---|

| Aluminum Alloy | $5 – $50 |

| Stainless Steel | $15 – $80 |

| Brass | $8 – $60 |

| Engineering Plastics | $2 – $30 |

CNC machining pricing is stable and supports highly flexible optimization and design.

Injection Molding Unit Price Range

| Production Volume | Per-Part Price |

|---|---|

| 10,000 pcs | $1 – $5 |

| 50,000 pcs | $0.5 – $2 |

| 100,000 pcs or above | $0.1 – $1 |

The larger the batch production quantity, the more obvious the cost advantage of injection molding.

Die Casting Unit Price Range

| Material | Per-Part Price |

|---|---|

| Aluminum Die Casting | $2 – $12 |

| Zinc Alloy Die Casting | $1 – $8 |

| Magnesium Alloy Die Casting | $4 – $15 |

Die casting balances cost and efficiency in metal batch manufacturing.

Production Volume Break-Even Analysis

Different production scales are suitable for different manufacturing solutions:

| Production Quantity | Recommended Process |

|---|---|

| 1 – 5,000 pcs | CNC Machining |

| 5,000 – 50,000 pcs | CNC or Die Casting |

| 50,000 – 500,000 pcs | Die Casting or Injection Molding |

| 500,000 pcs or above | Injection Molding |

When product demand is unstable or design is still being optimized, CNC machining is usually more economical.

Design Flexibility and Engineering Optimization Factors

Design for manufacturability plays a decisive role in mass production efficiency.

CNC machining supports rapid design adjustment with lower additional cost. However, injection molding and die casting processes usually require new mold development if structural modifications are involved.

Key design strategies to improve production efficiency include:

- Optimizing tolerance grades: Appropriately relaxing tolerance requirements for non-critical machining features to save time and cost

- Diversified material selection: During batch CNC production, materials with better cost advantages can be selected according to usage environments. For example, aluminum and stainless steel can sometimes be replaced with POM material, significantly reducing material cost

- Simplifying part structure: Structural adjustments can be made to unnecessary cavities or curved features to reduce multi-axis machining time and cost

- Modular product design: Producing difficult multi-surface complex structures in separated sections and assembling them later can greatly improve production efficiency

Engineering collaboration between manufacturers and suppliers can significantly improve production efficiency and reduce cost risk.

Hybrid Manufacturing Strategy

Many companies achieve performance and cost balance by combining multiple manufacturing processes.

Typical applications include:

- Die casting blanks + CNC precision finishing

- Injection molded housing + CNC metal structural components

- Transitioning from CNC prototype development to mold mass production

Hybrid manufacturing solutions help improve product performance and optimize cost structure.

Production Cycle and Delivery Efficiency Comparison

| Process | Tooling Development Cycle | Mass Production Efficiency |

|---|---|---|

| CNC Machining | 1 – 2 weeks | Moderate |

| Injection Molding | 4 – 10 weeks | Extremely Fast |

| Die Casting Process | 4 – 8 weeks | Fast |

CNC machining is suitable for rapid market introduction, while mold processes are suitable for long-term stable mass production.

When to Choose High Volume CNC Machining?

High volume CNC machining is usually suitable for the following situations:

Strict product precision requirements

Customers require high dimensional and precision consistency. Batch components requiring accuracy levels of 0.02 mm or higher require high assembly performance and stability.

Need for rapid market entry

Rapid production of hundreds to thousands of components can eliminate mold design optimization time cost and expense, as well as avoid subsequent mold idle waste. High volume CNC production can directly skip mold manufacturing and processing, enabling rapid and high-standard batch component production to enter the market within one week.

Future Development Trends of High-Volume Manufacturing

Modern manufacturing is developing toward intelligence, automation, and digitalization. CNC machining is gradually integrating with die casting and injection molding processes, forming a more flexible and efficient production system.

For example, mold-produced components can undergo batch CNC machining to remove excess material, avoiding additional mold optimization production for small batch component manufacturing.

Batch housing die casting processes sometimes act similarly to CNC rough milling. After batch housing die casting forming, components can enter CNC machining production lines to further process fillets, chamfers, grooves, cavities, threads, and tapping, improving assembly performance and standardization of die cast components.

Conclusion

High volume CNC machining for small/large components provides dimensional accuracy assurance for buyers with high-standard requirements. Traditional injection molding and die casting processes can also serve as complementary processes. For higher production quantity components, they can better reduce the manufacturing cost per component. Enterprises should comprehensively evaluate manufacturing solutions based on production scale, material machining performance, cost structure, time cost, and design flexibility. Through experimentation and multi-dimensional calculation evaluation, the best combined or single-process production workflow can be determined.

If you want get high volume cnc machining service or more details,you can feel free to contact with us.