Acrylic CNC machining manufacturers play a vital role in delivering high-precision transparent plastic components for industries ranging from electronics and lighting to medical devices and consumer products. As customers increasingly demand flawless clarity, tight tolerances, and scalable production, the expertise of professional acrylic CNC machining manufacturers becomes more important than ever.

Compared with generic machining providers, specialized acrylic CNC machining manufacturers understand the unique characteristics of acrylic, including its brittleness, melting sensitivity, and strict surface-finish requirements. Their skill directly affects product precision, optical clarity, and production consistency. This article explores how professional manufacturers operate, what makes them valuable, and how to evaluate acrylic CNC machining price for different project needs.

What Defines High-Level Acrylic CNC Machining Manufacturers?

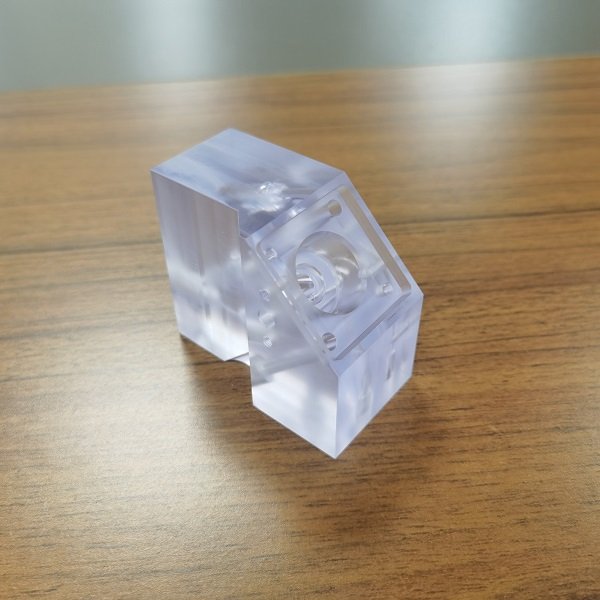

Top-tier acrylic CNC machining manufacturers combine material knowledge with advanced machining capabilities. They utilize high-accuracy CNC routers, mills, and polishing equipment to produce components with smooth edges, zero burrs, and perfect dimensional accuracy.

Unlike general-purpose machining workshops, acrylic CNC machining manufacturers often maintain dedicated clean areas to prevent scratches and contamination. Their process controls—including spindle speeds, feed rates, and coolant selection—are optimized specifically for acrylic.

Many customers also rely heavily on these suppliers for design support. Whether creating optical lenses, acrylic displays, fluid-control channels, or light-diffusion parts, the guidance provided by professional acrylic CNC machining manufacturers helps ensure the best structural strength and surface clarity.

How Acrylic CNC Machining Factories Ensure Precision in Every Part

A well-equipped acrylic CNC machining factory follows strict machining workflows designed to maintain stability and transparency. These factories adopt programming techniques that avoid tool-marking, overheating, and micro-cracking—issues that often occur when acrylic is machined incorrectly.

Most acrylic CNC machining factory processes include:

- Material inspection for purity and thickness consistency

- Multi-axis machining for detailed shapes

- Edge polishing (diamond polishing, flame polishing, or buffing)

- Cleaning and packaging to avoid scratches

- Optical inspection for clarity and uniformity

Because optical-grade parts require higher precision, customers often compare multiple acrylic CNC machining manufacturers to ensure that quality matches project expectations.

The Growing Demand for Custom Acrylic CNC Machining

Modern industries increasingly require custom acrylic CNC machining, especially in applications where transparency, lightweight structure, and strong aesthetics matter. For example:

- LED lighting housings

- High-transparency equipment windows

- Acrylic gears and mechanical components

- Retail display shelves

- Laboratory fluidic parts

- Touchscreen panels and control covers

Custom acrylic CNC machining enables unique geometries that cannot be produced through simple laser cutting or molding. With CNC methods, intricate details, threaded holes, curved surfaces, and multi-layer designs can be executed with high repeatability.

Professional acrylic CNC machining manufacturers also provide engineering recommendations such as wall-thickness optimization, stress-relief design, or rounding sharp corners to reduce crack risk.

Acrylic CNC Machining Service: What Customers Should Expect

A reliable acrylic CNC machining service includes far more than machining alone. Manufacturers typically offer end-to-end support, from material selection to post-processing and packaging.

Key services include:

- CAD/CAM programming

- CNC milling, routing, and turning

- Polishing and surface finishing

- Drilling, tapping, and engraving

- Bonding and assembly

- Quality inspection and optical evaluation

A comprehensive acrylic CNC machining service allows customers to complete their projects without relying on multiple vendors. This reduces delays, improves quality, and lowers overall risk.

The most advanced acrylic CNC machining manufacturers also integrate automated inspection tools to maintain consistent quality during high-volume production.

Factors That Affect Acrylic CNC Machining Price

Understanding acrylic CNC machining price helps customers select the right supplier and optimize product design. Several main factors determine pricing:

1. Part Complexity

Curved geometries, deep pockets, and multi-surface detailing increase machining time and cost.

2. Material Thickness and Grade

Cast acrylic is typically more expensive but offers better clarity and machinability than extruded acrylic.

3. Production Quantity

Higher volumes reduce the unit acrylic CNC machining price due to setup amortization.

4. Surface Finish Requirements

Optical polishing, flame polishing, or diamond finishing add labor and cost.

5. Tolerance Demands

Ultra-precise parts require slower cutting speeds and additional inspection.

6. Post-Processing and Assembly

Bonding, engraving, painting, or UV printing further affect cost.

Professional acrylic CNC machining manufacturers typically provide detailed quotations that break down machining steps, material costs, and finishing processes, helping customers understand cost structure more clearly.

Applications Across Industries That Depend on Acrylic CNC Machining Manufacturers

Because acrylic provides outstanding optical clarity and excellent structural stability, it is widely used across modern industries. Common applications include:

Consumer Electronics

- Transparent covers

- Light guides

- Protective windows

Medical Devices

- Diagnostic equipment panels

- Flow channels

- Transparent protective housings

Automotive and Transportation

- Instrument windows

- Light diffusers

- Decorative interior components

Retail and Display Industry

- Product stands

- LED display frames

- Custom signage

Industrial Equipment

- Protective machine windows

- Acrylic manifolds

- Control panel covers

In all of these sectors, acrylic CNC machining manufacturers provide unmatched precision and repeatability, ensuring that the material’s transparency and strength are preserved throughout production.

How to Choose the Right Acrylic CNC Machining Manufacturers

Selecting the right supplier affects the performance, appearance, and reliability of your final product. Consider the following checklist:

- Experience with optical-grade acrylic

- Availability of polishing and finishing options

- Ability to handle complex custom acrylic CNC machining projects

- Inspection capabilities such as optical measurement

- Sample quality and machining accuracy

- Transparent acrylic CNC machining price structure

- Production capacity and delivery time

Top acrylic CNC machining manufacturers can provide test samples, machining suggestions, and long-term production support, ensuring a seamless product lifecycle.

Conclusion

Acrylic CNC machining manufacturers deliver essential precision components for industries that demand clarity, strength, and aesthetic quality. By understanding how acrylic is machined, what services manufacturers provide, and what influences acrylic CNC machining price, customers can make smarter decisions and achieve higher-quality results. Whether you require prototypes or large-scale production, relying on specialized acrylic CNC machining manufacturers ensures consistent performance and professional-grade transparency in every part.

If you want to get more details or quote later,you can contact with us Weldo now.