The demand for highly transparent, precise, and visually appealing components has led many industries to rely on acrylic cnc machining prototype services. Acrylic (PMMA) provides excellent clarity, rigidity, and dimensional stability, making it ideal for optical housings, display parts, lighting components, medical covers, and engineering verification. This guide explains acrylic material options, machining processes, finishing methods, cost factors, and key precautions for producing a high-quality acrylic cnc machining sample or functional acrylic cnc machining part.

Why Acrylic Is Ideal for CNC Machined Prototypes

Acrylic is one of the clearest plastics available. Its optical-grade transparency, combined with robustness and ease of polishing, makes it suitable for prototypes that require both aesthetics and functionality.

Advantages of Using Acrylic

- Up to 92% light transmission, similar to glass

- Smooth, glossy machined surface

- Excellent dimensional stability

- Good rigidity and scratch resistance

- Lightweight yet durable

- UV and weather resistant

Because of these benefits, acrylic is frequently chosen for acrylic cnc machining prototypes used in product design, visual evaluation, and precision testing.

Common Applications of Acrylic CNC Machining Prototypes

Acrylic prototypes serve multiple industries that require clear visualization and accurate assembly validation.

Lighting and Optics

- Lenses

- Transparent light covers

- Light diffusers

Displays and Signage

- Retail display parts

- Transparent signage

- Protective windows

Medical and Laboratory Equipment

- Clear instrument covers

- Transparent fluid chambers

- Diagnostic casings

Consumer Electronics

- Acrylic display panels

- Protective housings

Engineering & Industrial Testing

Common acrylic cnc machining parts include:

- Transparent flow chambers

- Testing blocks

- Covers and brackets

- Viewing components

Acrylic Material Options for CNC Machining

Selecting the correct acrylic grade determines optical clarity and machining performance.

Cast Acrylic

- Higher clarity

- Less melting during machining

- Best for optical-grade prototypes

Extruded Acrylic

- More economical

- Slightly softer

- Good for general structural parts

Colored or Frosted Acrylic

- Used in lighting, branding, and decorative prototypes

How Acrylic CNC Machining Prototypes Are Produced

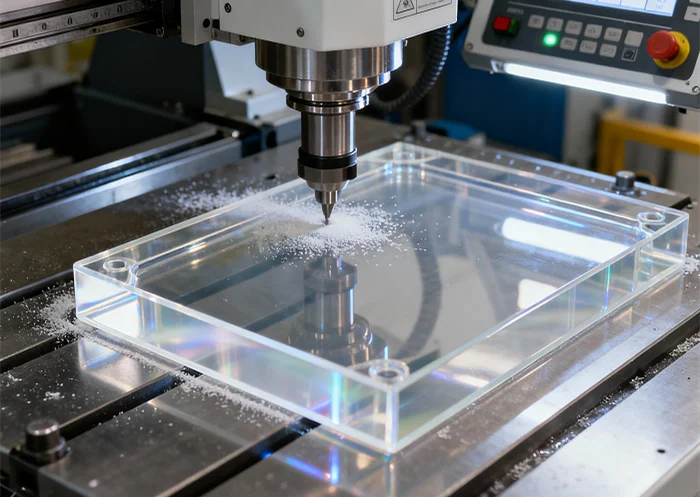

Producing a high-quality acrylic cnc machining prototype requires specialized machining strategies to maintain clarity and dimensional accuracy.

Step 1 — Engineering Review & DFM

Engineers analyze wall thickness, tolerances, tooling access, and finishing requirements to ensure the acrylic cnc machining sample meets specification.

Step 2 — CNC Milling,Turning and grinding

- Milling is used for pockets, windows, and flat surfaces

- Turning is used for cylindrical housings and round clear parts

- Grinding is used for flat surface grinding and polishing

Acrylic needs sharp cutting tools and controlled heat to avoid cloudiness.

Step 3 — Toolpath Optimization

To prevent melting:

- Use high spindle speed

- Use polished tools

- Maintain quick chip evacuation

Step 4 — Surface Finishing

Typical finishing:

- Diamond polishing

- Vapor polishing

- Flame polishing

- Fine sanding + buffing

This transforms machined surfaces into optical-grade clarity.

Step 5 — Assembly & Bonding

Acrylic parts may require adhesive bonding or mechanical fastening depending on prototype function.

Step 6 — Final Inspection

Inspection includes:

- Dimensional measurement

- Visual clarity check

- Crack detection

- Surface uniformity

Machining Precautions for Acrylic CNC Prototypes

Acrylic machining is more sensitive than other plastics. Proper handling ensures the best results for every acrylic cnc machining part.

1. Heat Buildup

Acrylic melts easily.

Solution:

- High spindle speed + light cut

- Air-blast cooling

- Polished single-flute cutters

2. Vibration & Chatter

Causes ripple lines and micro-chipping.

Solution:

- Reduce depth of cut

- Use sharp tools

- Strengthen fixturing

3. Cracking Around Thin Walls

Acrylic is brittle at thin sections.

Solution:

- Keep walls ≥ 1.5–2 mm

- Add fillets

- Reduce finishing pass load

4. Cloudy or Matte Surfaces

Caused by dull tools or aggressive cutting.

Solution:

- Diamond-polished tools

- Smaller stepovers

- Controlled finishing passes

5. Stress Whitening

Internal stress appears as white streaks.

Solution:

- Use cast acrylic

- Ensure smooth tool engagement

- Anneal thicker parts if needed

6. Burr Formation

Edges may collect soft burrs.

Solution:

- Sharp relief-angle cutters

- Light manual deburring

- Avoid heavy sanding

Tolerance and Accuracy Expectations

Acrylic prototypes offer excellent precision when machined properly.

- Standard: ±0.10–0.15 mm

- Precision: ±0.05–0.08 mm

- High precision: ±0.02–0.03 mm

Optical-grade prototypes may require additional polishing that slightly affects tolerance.

Cost Factors for Acrylic CNC Machining Prototypes

The cost of an acrylic cnc machining prototype depends on:

1. Material Type

Cast acrylic costs more but offers superior clarity.

2. Part Geometry

Deep pockets, thin walls, and optical features increase machining time.

3. Surface Finish

Optical polishing can account for 30–50% of prototype cost.

4. Quantity

Single pieces cost more; small batches reduce unit price.

5. Tolerance Requirements

Tighter tolerances require slower cutting and more finishing steps.

Design Tips for Better Acrylic CNC Machining Parts

Follow these guidelines to ensure better performance in prototypes:

- Add internal radii to reduce stress

- Maintain even wall thickness

- Avoid unnecessary polishing areas

- Include draft for visible surfaces

- Minimize deep thin-walled pockets

These practices help keep manufacturing cost-efficient while ensuring each acrylic cnc machining part meets performance expectations.

Why Choose Weldo Machining for Acrylic CNC Prototypes

Weldo Machining specializes in acrylic machining for industrial, optical, and consumer applications. We provide:

- Optical-grade clear machining

- Diamond, flame, and vapor polishing capability

- Tolerances as tight as ±0.02 mm

- Fast delivery for both prototypes and production

- Strong QC inspection for every acrylic cnc machining sample

- Engineering feedback during DFM review

Our experience ensures you receive consistent, high-quality acrylic prototypes that meet both visual and functional requirements.