Aluminium CNC machining is one of the most efficient ways to turn lightweight aluminium stock into precise, high-performance parts. From structural brackets and heatsinks to complex housings and fixtures, aluminium CNC machining combines fast cutting speeds, tight tolerances, and excellent surface finishes. In this guide, we’ll explore how aluminium CNC machining works, the role of modern aluminium cnc machining centres, key material choices, and the main advantages of cnc aluminium casting machining compared with solid billet machining.

What Is Aluminium CNC Machining?

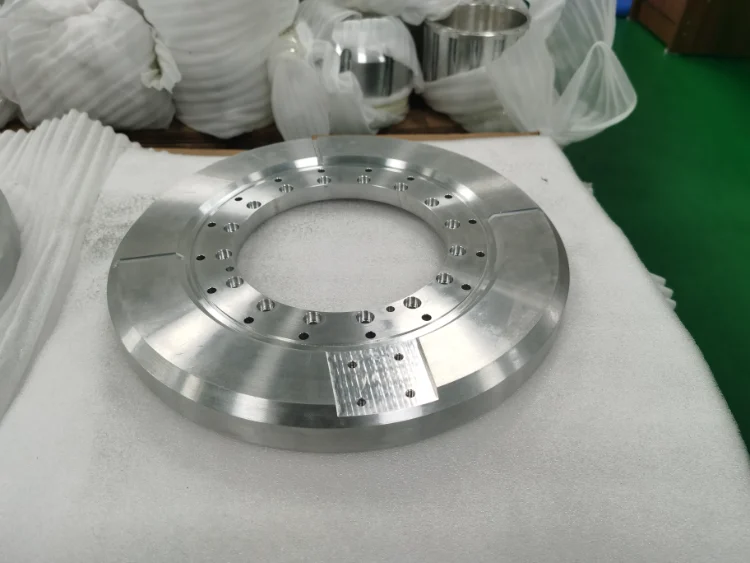

Aluminium cnc machining uses computer-controlled milling and turning machines to remove material from aluminium billets, plates, extrusions, or castings. Because aluminium is soft, thermally conductive, and easy to cut, it can be machined rapidly while still achieving high precision and stable dimensional accuracy.

A professional shop running advanced aluminium cnc machining centres can produce complex 3D profiles, tight-tolerance holes, pockets, grooves, and threaded features. Each aluminium cnc machining part is programmed from CAD/CAM data, allowing repeatable production from prototype to mass manufacturing.

Aluminium Grades Commonly Used for CNC Machining

Choosing the right aluminium alloy is a key part of successful aluminium cnc machining. Different grades offer different strength, corrosion resistance, and machinability.

6061 Aluminium

6061 is one of the most popular alloys in aluminium cnc milling machining service because it offers:

- Good strength-to-weight ratio

- Excellent machinability

- Easy anodizing and finishing

Typical applications include brackets, frames, fixtures, and general mechanical parts.

7075 Aluminium

7075 is used for high-strength applications:

- Very high tensile strength

- Slightly lower corrosion resistance than 6061

- Suitable for demanding aerospace or performance parts

An aluminium cnc machining part made from 7075 can replace heavier steel components in many designs.

6082 and 5052 Aluminium

6082 and 5052 are often used when enhanced corrosion resistance or specific forming characteristics are required. These alloys are common in structural components, marine fittings, enclosures, and profiles that still require precision aluminum cnc machining after extrusion or forming.

Aluminium CNC Machining Centres and Processes

Modern aluminium cnc machining centres are designed to take advantage of aluminium’s high cutting speed potential. These centres feature rigid spindles, automatic tool changers, and coolant systems that allow continuous high-speed machining.

3-Axis, 4-Axis, and 5-Axis Aluminium CNC Machining

- 3-axis machining handles most simple prismatic parts, pockets, slots, and drilled holes.

- 4-axis machining adds rotary motion for improved access around the part, reducing setups.

- 5-axis machining allows multi-face machining and complex surfaces in a single setup, ideal for intricate aluminium cnc machining part geometries.

Shops offering advanced aluminium cnc milling machining service often combine these capabilities to balance cost and complexity.

What an Aluminium CNC Milling Machining Service Includes

A complete aluminium cnc milling machining service goes beyond basic cutting. It usually includes:

- CAM programming and toolpath optimization

- Custom fixturing and workholding

- Roughing and high-speed finishing passes

- Drilling, tapping, and thread milling

- Deburring and basic edge finishing

For demanding industries, the service also covers dimensional inspection, CMM reports, and surface treatment coordination such as anodizing or powder coating.

Design Tips for a High-Quality Aluminium CNC Machining Part

Good design makes aluminum cnc machining faster and more economical. A few guidelines help engineers and buyers get better results and lower cost.

Recommended Wall Thickness and Features

- Keep minimum wall thickness around 1.0–1.5 mm for structural stability

- Use generous fillet radii in internal corners to match cutter geometry

- Avoid extremely deep pockets unless required for function

These choices reduce vibration, improve chip evacuation, and give a more stable aluminium cnc machining part.

Tolerances and Surface Finish

Aluminium allows tight tolerances, but not all surfaces need ultra-precision. Typical values:

- General features: ±0.05 mm

- Critical fits: ±0.01–0.02 mm

Advantages of CNC Aluminium Casting Machining

In some projects, you may start from cast aluminium rather than solid billet. Understanding the advantages of cnc aluminium casting machining helps you choose the right route.

Casting + CNC: Best of Both Worlds

CNC machining aluminium castings allows you to:

- Use cast near-net shapes for complex geometry

- Reduce raw material waste compared with solid billet

- Maintain critical dimensions by machining functional faces and holes

This hybrid approach delivers the visual and structural benefits of casting while still benefiting from precise aluminum cnc machining on key surfaces.

Functional and Economic Benefits

When part volumes are high enough, the advantages of cnc aluminium casting machining include lower per-piece cost, consistent external shape, and improved branding features such as cast logos and textures. CNC finishing ensures that sealing surfaces, bearing bores, and mounting faces still meet demanding tolerance requirements.

Typical Applications of Aluminium CNC Machining

Because aluminium is strong, light, and corrosion resistant, aluminum cnc machining is used across many industries.

Automotive and Motorsport

- Engine brackets

- Transmission housings

- Suspension components

- Lightweight structural parts

These often rely on multi-axis aluminium cnc machining centres to achieve complex shapes and weight-optimized structures.

Aerospace and UAV Components

- Structural ribs and frames

- Precision housings and covers

- Mounts and brackets for avionics

Here, an aluminium cnc machining part must deliver excellent strength-to-weight performance and consistent repeatability.

Electronics, Robotics, and Industrial Equipment

- Heatsinks and cooling plates

- Sensor housings

- Robotics end effectors and joints

An effective aluminium cnc milling machining service helps integrate mechanical design requirements with thermal and assembly constraints.

How to Choose an Aluminium CNC Machining Partner

Picking the right supplier for aluminum cnc machining is critical for long-term success.

Check Aluminium CNC Machining Centres and Capacity

Look for:

- Modern vertical and horizontal machining centres

- 4-axis/5-axis capability for complex geometry

- High-speed spindles optimized for aluminium

- Stable fixturing and in-process inspection

Suppliers with strong aluminium cnc machining centres can maintain quality even at higher volumes.

Review Experience With Your Part Type

Ask for examples of similar aluminium cnc machining part projects, industries served, and typical tolerances. Experience with thin walls, deep pockets, or tight positional tolerances is particularly valuable.

Evaluate Quality Control and Communication

Serious providers offer:

- Material traceability

- CMM or precision inspection reports

- Clear drawing review and DFM feedback

- Transparent lead time and cost estimates

All of these support smoother aluminium cnc machining workflows and fewer surprises.

Work With Weldo Machining for Aluminium CNC Machining

When you need a reliable partner for aluminium cnc machining, choosing a supplier with strong engineering support, advanced machining centres, and experience across multiple industries makes all the difference. Weldo Machining offers precision aluminium cnc milling machining service, supports complex multi-axis work, and produces custom aluminium cnc machining part solutions from prototypes to batch production. If you are exploring billet machining, cast part finishing, or want to understand the full advantages of cnc aluminium casting machining, our technical team can help you choose the best process.

For detailed quotations, lead times, and engineering advice on aluminum cnc machining, you can contact Weldo Machining to discuss your drawings, tolerances, and material requirements.

FAQ of aluminium cnc machining

What is aluminium CNC machining?

Aluminium cnc machining is the process of using computer-controlled milling and turning machines to cut aluminium into precise shapes, features, and assemblies based on digital CAD models.

Why use aluminium instead of steel for CNC machining?

Aluminium is lighter, easier to machine, and offers excellent strength-to-weight ratio. This makes aluminium cnc machining ideal for aerospace, automotive, and electronics where weight and heat dissipation matter.

What are aluminium CNC machining centres?

Aluminium cnc machining centres are specialized CNC machines designed with high-speed spindles, optimized tooling, and coolant systems that allow fast, accurate machining of aluminium alloys.

Can CNC machining be used on aluminium castings?

Yes. One of the key advantages of cnc aluminium casting machining is that you can cast near-net shapes and then CNC-machine critical surfaces, holes, and sealing areas to tight tolerances.